STEP responds to "double carbon" and creates high-quality cooling tower frequency conversion solutions

- Views:

- Time of issue:2022-11-21 00:00

STEP responds to "double carbon" and creates high-quality cooling tower frequency conversion solutions

- Views:

- Time of issue:2022-11-21 00:00

Cooling towers are widely used in air-conditioning cooling systems and industrial water cooling fields such as aluminum profile processing, steam turbines, tanning, power generation, injection molding, foaming, and air compressors.

As a leading enterprise in the field of industrial control, STEP has mastered the core technology of variable frequency drive and has accumulated rich experience in industrial applications. It has developed a driving layer solution for cooling towers with AS170Plus frequency converter + permanent magnet direct drive motor, which has low noise and high torque. Large size, good control performance, high protection level, and convenient maintenance, etc., help customers produce higher value-added and competitive products, and also use practical actions to help achieve the "double carbon" goal.

#01 Introduction to Working Principle of Cooling Tower

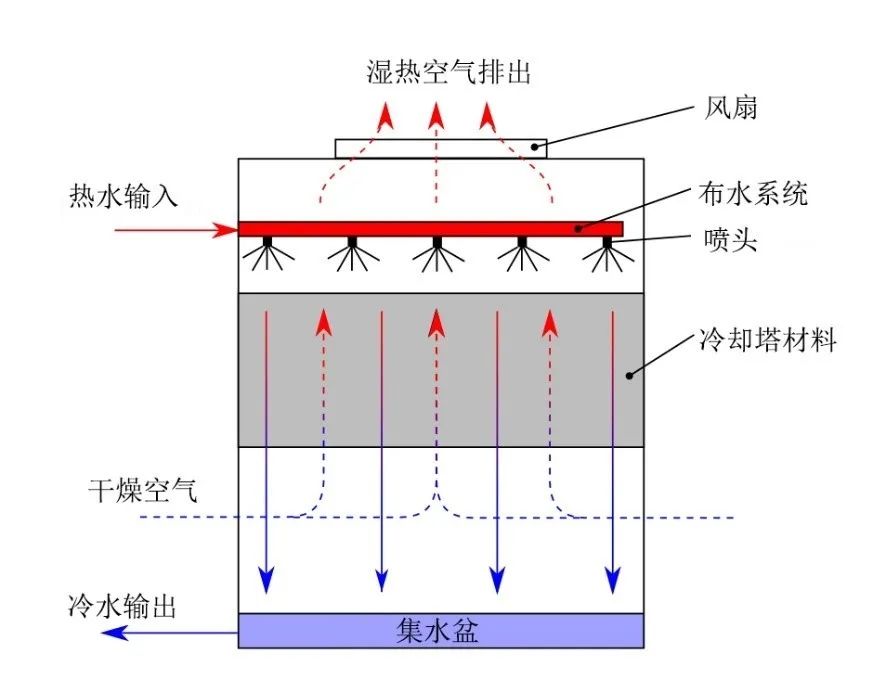

Working principle diagram of cooling tower

A cooling tower is a device that cools water, generally consisting of a sump, a ventilation tower, a water distribution pipe, a fan, and a water eliminator. The water pump presses the hot water into the water distribution pipe, sprays the hot water evenly on the filler with the help of the nozzle on the pipe, and forms a water film, and at the same time exchanges heat with the dry air flowing in from the bottom of the ventilation tower to evaporate and take away the heat in the air. The cooling water drips into the sump at the bottom and continues to be recycled.

The evaporation of water into the air is not endless. With the increase of air humidity, when the air on the water-air contact surface reaches saturation, the water molecules cannot evaporate. At this time, a fan is needed to send the hot and humid air to the air. High altitude to prevent backflow, and continuously inhale dry air from the bottom of the cooling tower, so that there is air flow inside the cooling tower. The role of the fan in the whole process is to increase the air supply volume and speed up the air flow to facilitate heat exchange.

#02 Cooling Tower Fan Features

√ Large moment of inertia;

√ There may be an initial speed before starting;

√ PID control with temperature as the control object is commonly used;

√ Working in a relatively humid environment for a long time;

√ Loud noise, easy to cause resonance;

√ It can adopt multiple driving methods such as direct drive, gearbox and belt.

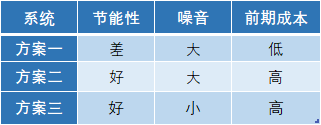

#03 Cooling Tower Fan Control Scheme

Option 1: Inverter + asynchronous motor + gearbox/belt + fan

Solution 2: Inverter + Permanent Magnet Synchronous Motor + Gearbox/Belt + Fan

Solution 3: Inverter + permanent magnet direct drive motor + fan

Option One

Advantages: low initial investment cost and simple debugging.

Disadvantages: high power consumption, poor control performance, poor system stability, high maintenance cost, and high noise.

Option II

Advantages: Compared with Option 1, it has the following advantages

① energy saving;

②Large torque, high efficiency and strong overload capacity;

③ Good control performance, high control precision and fast response;

④The motor is smaller in size, easy to install and maintain in weight;

⑤ High protection level and long service life.

shortcoming:

The upfront cost is high, and because the fan is driven by the gearbox, the system stability is poor, the maintenance cost is high, and the noise is loud.

third solution

Advantages: Compared with the second solution, the motor directly drives the fan, and the dragging structure in the middle is removed, the structure is stable, the installation is convenient, the control performance is good, the precision is high, the system stability is high, the wear is reduced, and there is almost no need for maintenance in the later stage.

Cons: High upfront cost.

#04 Cooling Tower Energy Efficiency

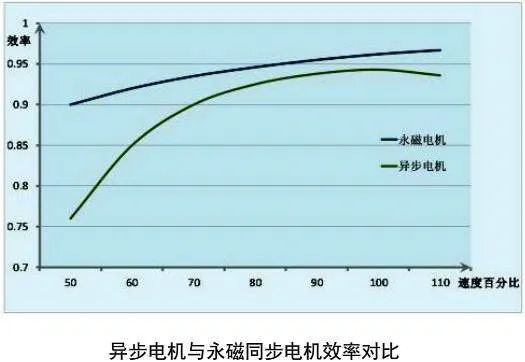

In the fan control system, energy saving has become the main concern of many customers. The following figure shows the efficiency comparison of asynchronous motor and permanent magnet synchronous motor.

At 50% speed, the efficiency of permanent magnet motor reaches 90%, while the efficiency of asynchronous motor is only about 76%. The efficiency of permanent magnet motor is about 14% higher than that of asynchronous motor; when the speed is about 100%, the efficiency of permanent magnet motor can reach 96%. %, while the efficiency of asynchronous motors almost reaches the maximum value, about 94%; the efficiency of permanent magnet synchronous motors is about 2%~14% higher than that of asynchronous motors. Taking 55kw as an example, assuming an average operation of 20 hours a day, 330 a year day, the electricity fee is 0.7 yuan/kWh, then:

Energy saving: 55kw×(2%~14%)=1.1kw~7.7kw

Cost saving: (1.1kw~7.7kw)×20h×330 days×0.7 yuan/degree=(5082~35,574) yuan

Compared with asynchronous motors, permanent magnet synchronous motors have good energy-saving effects and can save a considerable amount of electricity. In addition to meeting the needs of asynchronous motors, permanent magnet synchronous and permanent magnet direct drives, STEP inverters have corresponding solutions, especially the "STEP inverter + permanent magnet direct drive" scheme not only retains the good performance of permanent magnet synchronous motors The energy-saving effect also improves the control accuracy of the system, reduces noise, and reduces maintenance costs.

#05 STEP Inverter Features

Various installation methods: According to different schemes and different working conditions, cabinet machines and all-in-one machines (inverter + motor) are optional.

Match a variety of motor types: such as asynchronous motors, permanent magnet synchronous motors, permanent magnet direct drive motors, reluctance motors, etc.

High protection level: The protection level of AS170Plus is IP55, which can be combined with permanent magnet direct drive motor to form an integrated machine.

Intelligent functional design:

√ Solve the pain points of cooling tower fans working in harsh environments such as cold and humidity;

√ Solve problems such as resonance, communication failure and shutdown;

√ Make the cooling tower fan system have good self-diagnosis and self-protection capabilities.

#06 COOLING TOWER APPLICATIONS

Case 1: Inverter + asynchronous motor

main feature:

By setting the built-in PID function of the inverter, the closed-loop control is completed with temperature as the control object;

Control the switching between motor frequency conversion and industrial frequency through frequency detection upper limit and lower limit;

Set the acceleration and deceleration rounded corners to make the fan start and stop more smoothly;

With flying start, when the fan is reversed by external wind force or has an initial speed, flying start can make the fan start smoothly and without impact.

Case 2: Inverter (cabinet machine) + permanent magnet direct drive

The frequency converter used in this application is AS500, which is installed in the control cabinet:

main feature:

The permanent magnet direct drive method has the advantages of high efficiency and energy saving, high control precision, good control performance, and large starting torque compared with the use of gearboxes/belts. It can be used in conjunction with AS500 inverters to provide customers with Bring a smarter user experience, improve convenience, and reduce maintenance costs.

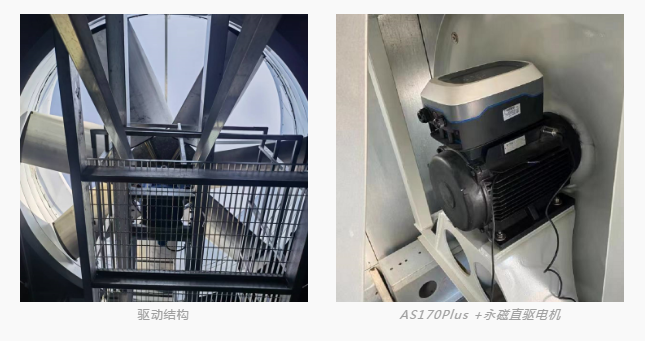

Case 3: Inverter (integrated machine) + permanent magnet direct drive

As shown in the figure, the frequency converter has a high protection level and is directly installed on the motor. It has a simple structure, convenient installation, high efficiency, large torque, good control performance, low noise, and almost no maintenance.

Scan the QR code to read on your phone