Strategize and aim at thousands of "lithium"! New SCARA products dedicated to the STEP lithium battery industry are released

- Views:

- Time of issue:2022-11-17 00:00

Strategize and aim at thousands of "lithium"! New SCARA products dedicated to the STEP lithium battery industry are released

- Views:

- Time of issue:2022-11-17 00:00

In 2008, Zhongweixing, a subsidiary of STEP, entered the field of SCARA robots with the attitude of a domestic pioneer. Since then, the products have continuously conveyed their brand attitude and strength in the market, leading the innovation and reform of the industry. By unlocking more scene applications, they truly Create landing value for customers.

Against the backdrop of global energy transformation, STEP will make in-depth plans for the lithium battery industry in 2021, launching a 50kg heavy-duty SCARA, which has attracted other brands to follow suit and has also received good market feedback. Now, witnessing the transformation and upgrading of the manufacturing industry and the rapid increase of lithium batteries in new energy vehicles and energy storage applications, STEP has once again led the way and announced the update and upgrade of its SCARA product family, for AR series, YR series, and FR series models At the same time, the WR series side-mounted SCARA will also make a new appearance.

This updated SCARA has a total of 20 models, the arm length covers 350mm-1200mm, the maximum load is 20kg, and there are three installation methods: front installation, reverse installation and side installation. These new models further enrich the product matrix of STEPSCARA's full range. Thanks to the diversification of optional models and installation methods, STEPSCARA can accurately carry out efficient handling operations in the process links of lithium battery cell stacking, assembly, liquid injection, plugging and pulling out nails, chemical capacity separation, and module segment inspection. , to provide more efficient and cost-effective robot solutions for the full-scenario and full-process intelligent manufacturing of lithium batteries, and help users effectively improve production efficiency and product quality.

Flexible modular design

From the integration of drive and control to the integration of video and control, almost every important node of domestic SCARA technological change has STEP. This time, the STEPSCARA product team once again leads the industry trend. The body of the new SCARA adopts a highly modular structural design, which integrates core components such as the base, machine cover, screw cover, and large and small arms into parts, which can quickly provide users with Customized SCARA models with arm length and installation methods to meet your needs.

Rigid upgrade of special research and development

In terms of product research and development, STEP adheres to the orientation of solving the pain points of the industry, promotes the continuous innovation of lithium battery production technology, and brings new value breakthroughs to the industry. This time, STEP carried out a special research and development of pre-stacked module section technology for double-station gluing machine and small surface gluing process. By adding two guide rod accessories to the main body, the rigidity of the robot was improved to meet the requirements of the process . Requirements for robot rhythm, stability, and gluing accuracy.

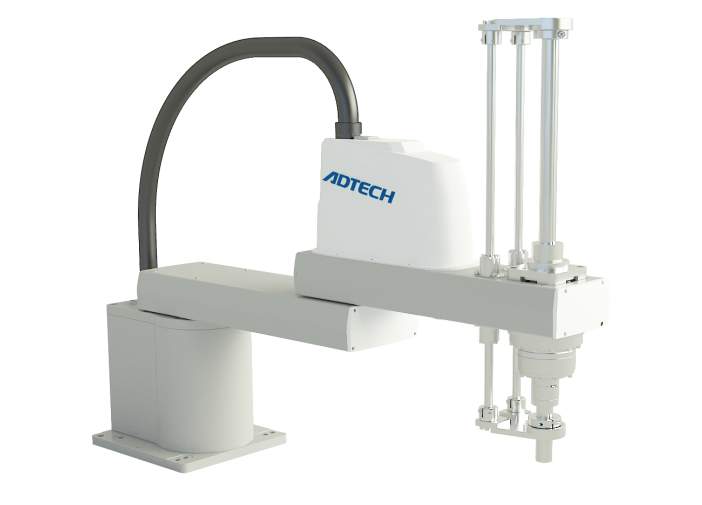

YR81030 SCARA robot

Persist in "fast, precise and stable"

In terms of product performance, it will continue to benchmark international first-line brands. The new SCARA focuses on the details, reduces the volume of the hood by 35%, effectively reduces the running wind resistance, and at the same time optimizes and upgrades the rigidity of the arm, J4 axis, and J3 axis. , The key performance indicators of the robot, such as operating rhythm, stopping accuracy, eccentric load capacity, and stability, have been greatly improved. Among them, the repeated positioning accuracy of the XY axis is increased by 50%, and the repeated positioning accuracy of the Z axis is increased by 100%. The rated J4-axis allowable moment of inertia is increased by 300%, and the maximum allowable moment of inertia of the J4-axis is increased by 120%.

Protection clean upgrade

In sensitive industries such as lithium batteries, food, medicine, semiconductors, glass, photovoltaics, etc., production requires a clean room environment to avoid foreign matter from reducing product yield and safety. Reached ISO Class 5, prevent oil and particulates and other pollutants from leaking. It is worth mentioning that STEP has also created a protection system comparable to a "golden bell cover" for the new SCARA, raising the protection level to IP65. The robot has also achieved a major leap in coping with harsh, complex and changeable working environments.

Under the guidance of the "dual carbon" goal, new energy is "riding the wind and waves", and intelligent manufacturing has become the biggest driver of industry progress. STEP will always be supported by a comprehensive robot, operation and control product line and solid technology to provide partners with higher precision, higher efficiency, and more stable intelligent solutions, and promote the new energy industry to continuously create a new situation of high-quality development .

Scan the QR code to read on your phone