Research and practice of usability technology of STEP operation and control products

- Views:

- Time of issue:2021-01-08 16:51

Research and practice of usability technology of STEP operation and control products

- Views:

- Time of issue:2021-01-08 16:51

The "2021 China Motion Control/Direct Drive Industry Summit Forum" was grandly held in Shenzhen on December 17, 2020. More than 500 people in the industry gathered together to plan for the development of the industry.

Dr. Wang Ke, STEP Central Research Institute

In the sub-forum on motion control technology, Dr. Wang Ke from STEP Academia Sinica gave a speech titled "Research and Practice on Usability Technology of Motion Control Products". Through intelligence, digital twins, networked operation and maintenance, and ease of operation, he shared some feelings about motion control technology. The following content is organized according to the speech.

Under the commercialization mode of industrial products, ease of use has become a new core competition point, and under the current background of intelligent manufacturing, ease of use has more different interpretations. For example, intelligence, whether the product is free of debugging, environmental adaptability, and digital twins. So how do we improve usability based on this? For example: programming-free robots, model simulation, and visualization, networked operations, and operation and maintenance, based on predictive maintenance.

1. Intelligent debugging-free

Intelligent and debugging-free technology is a comprehensive technology, which involves all aspects of the servo, such as the current loop, and it is related to the hardware current loop, such as the FPGA hardware current loop, as well as the identification of the body parameters, the identification of the hardware structure, and the prediction of the current. In the speed loop, there are online identification, speed pulsation suppression, adaptive online mechanical resonance suppression technology, speed observation, etc. Among them, V-type vibration suppression is our unique technology. Friction damping identification and over-quadrant protrusion suppression technology are also our advanced technologies, including one-button parameter setting, automatic switching of module algorithms in different environments, and also support third-party motors. Vibration is complex, including terminal vibration, mechanical resonance, and its own interaction vibration. These technologies are used in the new generation of products.

Intelligent complex environment adaptation. What our country is doing now is to replace human beings, and machine vision is a major trend in the future. Traditional machine vision can no longer adapt to various complex environments, and our AI algorithm is needed here. For example, the seasoning packets are stacked together and cannot be separated. Visual AI algorithms, such as the relatively mature LeNet-5 algorithm, are divided into two to three levels of convolution, deep learning, layer-by-layer screening, and then full connection, and finally form a set of training models.

The whole process is the same as our usual training process, and this experiment is shorter than we thought. We trained with 200 pictures, and then verified that the recognition time is less than 1 millisecond, which means that we can use it in many occasions. In the past, we thought that the AI algorithm took a long time, which depended on mixing the training model and the execution model, and the execution was not so slow. In addition, in terms of ease of use, we can add voice control, human recognition, and gesture recognition to many operations, which are all an upgrade to human-computer interaction. Voice control is also a relatively mature algorithm, which does some convolution and time series processing.

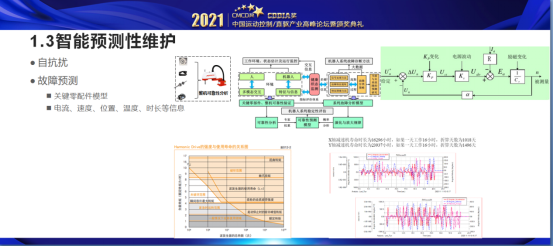

Based on predictive maintenance. The first is the model of some key spare parts, which will be based on the understanding of reducers, motors and other equipment, and make some models for the combination of current and speed. Then combined with big data, life expectancy is provided.

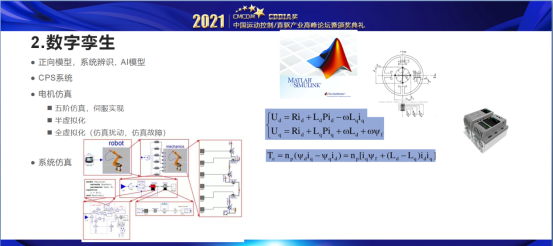

2. Digital twin

Our advantage lies in adopting many ways to realize on the embedded system, but it is difficult for matlab to run on the single-chip microcomputer. How to build the model? There are many ways here, one is called the forward model, the formula of a typical motor is shown in the figure, which can be used for modeling, and it is integrated in our company's servo. There are also some advanced servo simulations on the controller side, such as how to simulate its disturbances and faults.

3. Network operation and maintenance

For us, it is mainly to provide some spare parts, how to access the cloud? The combination of edge controllers is now advocated. What is an edge controller? Not only to collect data, the edge is more emphasis on collaboration in the cloud, and collaboration with other edge layers. This kind of controller is also a new concept, as long as the real and non-real are distinguished, it is not difficult. On a real-time network, TSN is an important third-party standard protocol and an important technology of choice in the future; there are some more open ones on the upper-layer network, such as OPC UA. OPC UA TSN is an important cross-OT and cross-automation real-time technology. We have a lot of clouds, such as Alibaba Cloud, Tencent Cloud, and Huawei Cloud, and we have a unified architecture to access the cloud. The picture below shows the software we can provide, such as cloud debugging, there are more cross-platform UIs now, mobile phones, computers, we have also launched software for debugging servos, including cloud firmware upgrades.

Which controllers have these functions? Here is a collection of STEP and popular controllers. Both PLC and industrial control machines have cloud edge computing functions. The top layer is STEP Automation Studio, which provides tools for visual configuration, secondary development tools, and cloud configuration networking. tool.

4. Ease of operation

Regarding ease of operation, how about one-handed operation? We have done different experiments to ensure safety and reliability, and the method with LED lights next to the terminals can be solved.

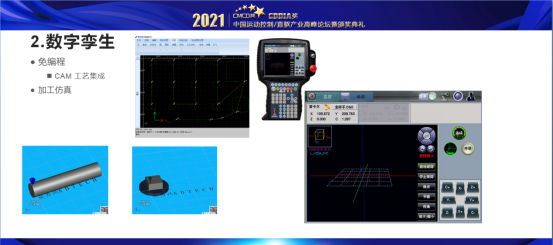

On the basis of PLC, we provide Chinese programming, which is a very practical programming method; we also provide CAM-based system free programming, and engineering wizards. If the customer wants to make an application, they can directly generate a robot, motion control, or PLC project through the engineering wizard, then configure and configure it through visual programming, and finally complete their own application project through the service-oriented architecture and interface we provide . The service-oriented architecture and interface are not widely used in our industry. It is how to make our functions service-oriented. We have a set of maintenance backgrounds, such as our alarm system.

In the deep cultivation of industry applications, the more industrial technologies are provided for users, the more convenient it is for users to use. We have made some technology packages to facilitate the integration of users.

Scan the QR code to read on your phone