Continue to give strength | Zhongweixing boosts the production of masks and presses the "fast forward button"

- Views:

- Time of issue:2020-03-30 00:00

Continue to give strength | Zhongweixing boosts the production of masks and presses the "fast forward button"

- Views:

- Time of issue:2020-03-30 00:00

[STEP Group丨Zhongweixing]Nowadays, the country has passed the darkest moment of the epidemic, while the epidemic prevention situation overseas is becoming more and more severe, medical supplies are consumed in large quantities, and the demand for mask machines in the market continues to heat up.

Trust the relationship, find an acquaintance to get a mask machine, or buy a blueprint for 10 yuan in a certain treasure, and develop it yourself according to the picture, but in the end you find that it is not the price that defeats you, but the equipment debugging.

The so-called "three points to do, seven points to adjust", due to the length of the mask machine line, the large number of parts, and the soft material of the mask, the stability is poor. After the equipment is assembled, many technical parameters need to be adjusted to the optimal state. This is related to Core performance such as machine failure rate and yield rate.

The entire debugging process is highly dependent on the experience of the engineer. If more efficient PLC programming and an easier-to-operate HMI human-machine interface are added at the same time, the debugging efficiency can also be improved.

For example,

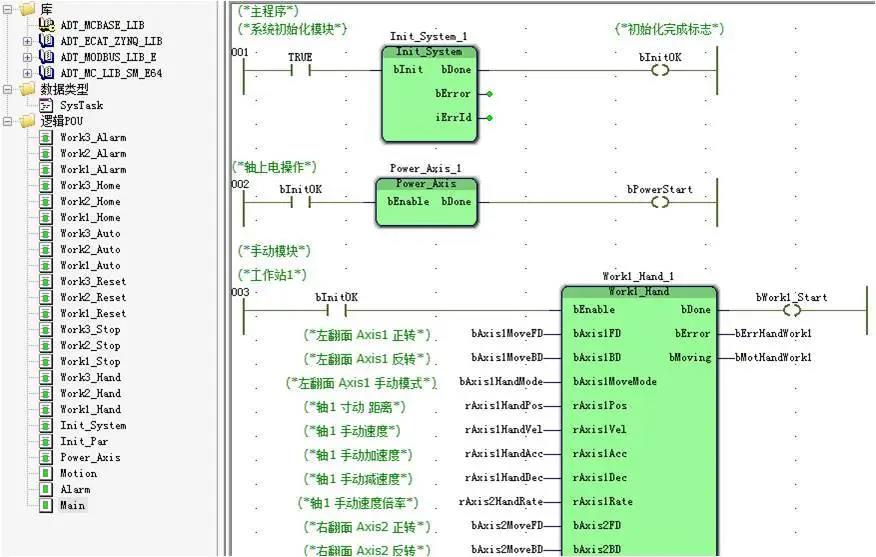

PLC programming adopts function block calls, which can clearly display the real-time status of the status, which is convenient for finding problems in a targeted manner

;

Recently, Zhongweixing took the AMC1600E bus controller as the core, and designed a fully automatic "one-to-two" planar mask machine control scheme that successfully passed the customer's acceptance.

The customer's mask production line is being debugged on site

This solution adopts bus control, which facilitates the expansion of external IO on the basis of improving the operation response speed and increasing control accuracy; the PLCOpen motion control command library can easily meet various motion requirements in mask production; use IEC61131-3 standard language (IL, FBD, SFC, ST, LD) for programming, give full play to the flexibility of ST language, write tedious and complex actions in function blocks, and make the operation call more simple and clear.

Equipment introduction

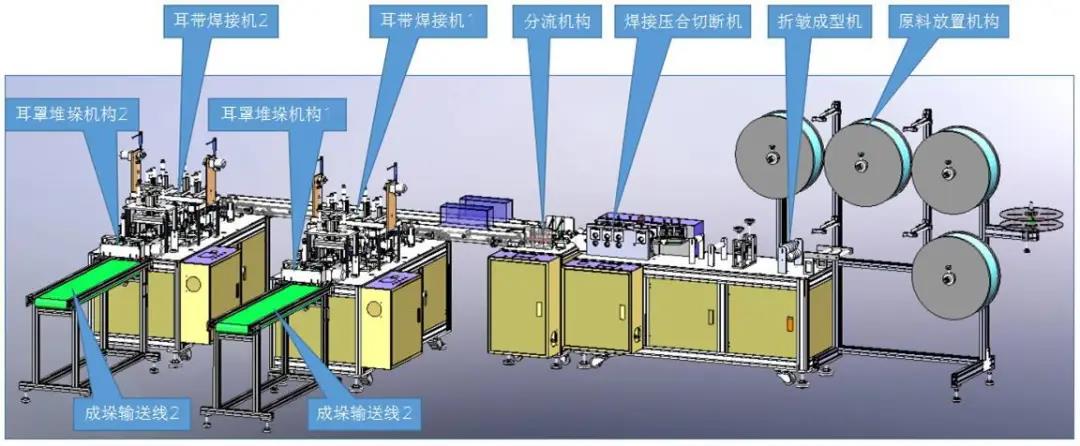

Equipment composition (click to enlarge)

This scheme is suitable for the fully automated production of flat masks, mainly including coil material feeding, folding synthesis, nose bridge feeding, mask forming, mask cutting, ear strap feeding and welding, and finished product blanking. The equipment can also be regarded as a printing machine. It consists of three parts: sheeting, slicing, and welding. The equipment can complete the entire production process from coil raw materials to finished masks. The masks produced are comfortable to wear and have no sense of pressure. Among them, according to the needs of users, the turning and distributing motors can be changed to cylinder actions, which is beneficial to reduce the use of motors.

Electrical Parts List

*The above only lists the parts provided by Zhongweixing

Electrical system configuration

PLC program introduction

The program is mainly divided into three parts: main program, alarm and automatic operation.

Through the use of ST language, many complex actions are integrated with FBD function blocks according to the equipment station, and the function blocks are called in the three main programs, which not only facilitates the reasonable division of difficult and easy programs in the programming process, but also ensures that during the equipment debugging process, Avoid the display of too many irrelevant variables, thereby improving the readability of the program, and finally use the multi-tasking mechanism to run the main program easily.

HMI Human Machine Interface

The HMI man-machine interface is divided into automatic, manual, parameter, function, alarm and other pages.

Automatic interface: mainly includes the real-time position display of the axis position, equipment production count statistics, start, stop, reset, zero return, pause, clear and other operation functions of different stations.

Manual operation interface: Firstly, it is divided into manual interfaces of different stations, and then the state interfaces of different stations include manual motor operation interface, manual cylinder operation interface and sensor monitoring interface.

Parameter page: divide the interface according to different workstations, and set the corresponding manual, automatic and zero return parameters in different interfaces.

Alarm interface: It includes real-time alarm and historical alarm interface. The alarm information includes date, time and specific time of occurrence. Historical alarm can query the alarm information within one week.

Next, let's take a look at a video demonstration to experience the operation process of the HMI human-machine interface→

Scan the QR code to read on your phone