VC+VR | Shanghai Xiaoao demonstrates virtual commissioning production technology

- Views:

- Time of issue:2017-09-14 00:00

VC+VR | Shanghai Xiaoao demonstrates virtual commissioning production technology

- Views:

- Time of issue:2017-09-14 00:00

The 2017 Shanghai International Automobile Manufacturing Technology, Assembly and Materials Exhibition was held at the Shanghai New International Expo Center on September 5-8. Shanghai Xiaoao Xiangrong Automotive Industry Equipment Co., Ltd. and Shanghai STEP Robot Co., Ltd. jointly participated in the exhibition.

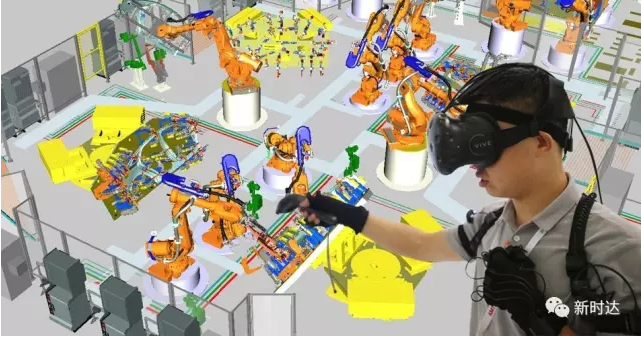

VC+VR virtual debugging technology display

VC+VR virtual debugging production technology

Xiaoao virtual debugging is an electrical debugging technology based on digital simulation technology. Through the combination of simulation environment and physical PLC, HMI and other automation equipment, the joint debugging of PLC program and robot program can be completed, and the design and program can be verified in advance before construction, thereby reducing risk costs and improving project quality.

Using Xiaoao virtual debugging technology can greatly shorten the on-site debugging cycle, reduce downtime, train operators in a virtual environment, reduce on-site PLC program errors, improve the quality of on-site robot trajectory, reduce the workload of engineers on site, and provide safe test environment.

NC Locator Flexible Positioning System

NC Locator flexible positioning system is

a standard product independently developed by Xiaoao based on the servo control technology of STEP robots. It is mainly used for floor positioning of various models. It can be applied to the welding and assembly workshop: base plate sub-assembly line (front and rear base plate lines, warehouse delivery lines, etc.), base plate main line, general assembly line, repair welding line, etc., suitable for multi-model collinear flexible production.

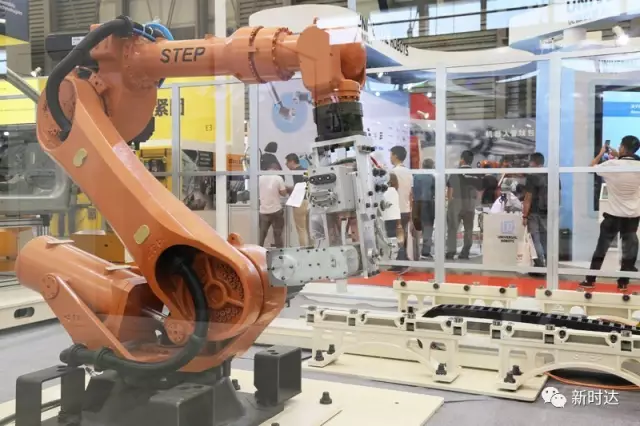

Robotic servo welding system with additional axes

The robot servo welding system with additional axis

Xiaoao robot outer axis track cooperates with STEP robot control technology. It can be used in standard spot welding, handling, gluing and other occasions. Modular design, compact structure, easy to plan and arrange. Integral frame reduces installation and adjustment time. The positioning repeatability is good, and it can be adapted to various robot brands.

At the booth at the same time, Xiaoao also displayed products and technologies such as robot riveting system, high-speed roller bed and positioning trolley, and tooling automatic switching system.

Xiaoao Booth

Scan the QR code to read on your phone