STEP launched VD8849, which can realize programming and visual debugging at the same time on the PC side

- Views:

- Time of issue:2021-08-27 00:00

STEP launched VD8849, which can realize programming and visual debugging at the same time on the PC side

- Views:

- Time of issue:2021-08-27 00:00

The miniaturization of electronic products and more concentrated internal chips have led to explosive growth of visual dispensing equipment. As the core brain of the entire equipment, the dispensing controller is used to solve the technological problems of the dispensing process control. Through data communication with the machine vision positioning system, it can control the "precision" for complex working environments. In terms of the teaching method, it is flexible and convenient to edit dispensing paths and configure parameters through handheld teaching. However, some users’ needs for PC-side interactive experience should not be ignored.

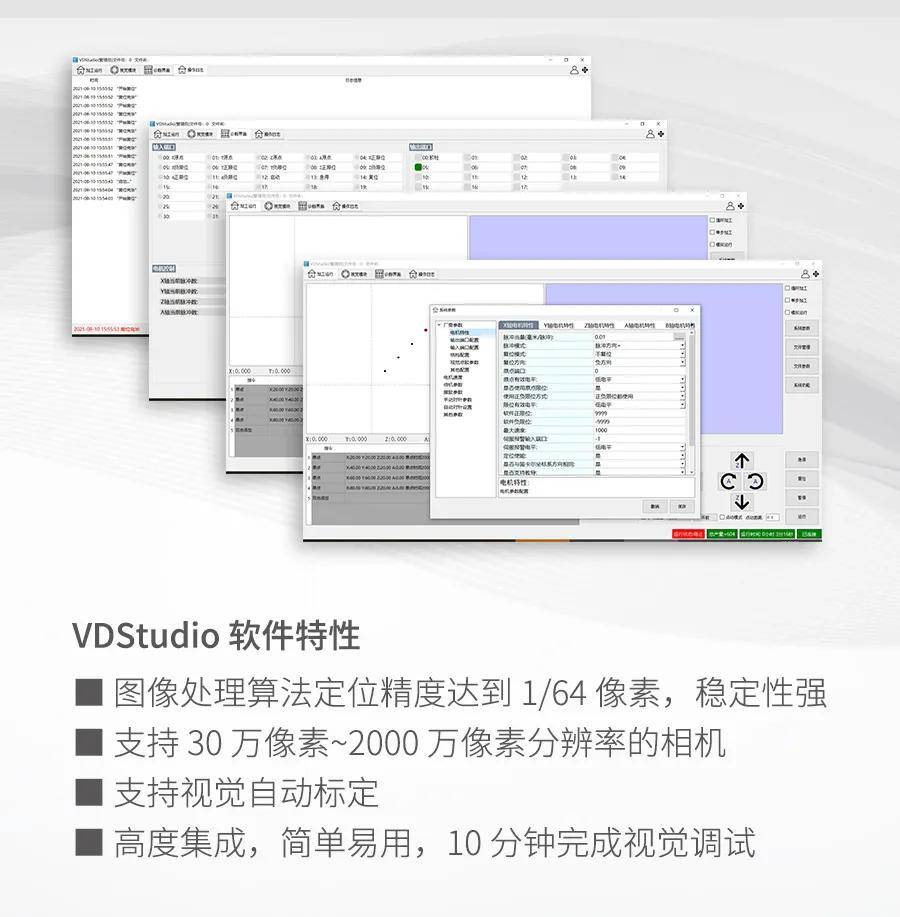

STEP's latest multi-functional embedded visual dispensing control system VD8849, hands-free teaching pendant, through the VDStudio host computer software, can simultaneously realize a series of operations such as programming, visual debugging, diagnosis and operation log recording on the PC side.

In terms of hardware, VD8849 has been enhanced compared with the previous generation. It is composed of AVS2610 vision system + motion controller based on OMC system. The devices are connected through network communication. The AVS2610 industrial computer is used for visual inspection, and the offline motion control card Then complete the operation of motion control and IO port, which ensures the high precision of dispensing as a whole.

Video: Processing Demonstration of VD8849 Dispensing Control System

Next, let's take a closer look at the biggest highlight of VD8849——VDStudio, according to the function blocks!

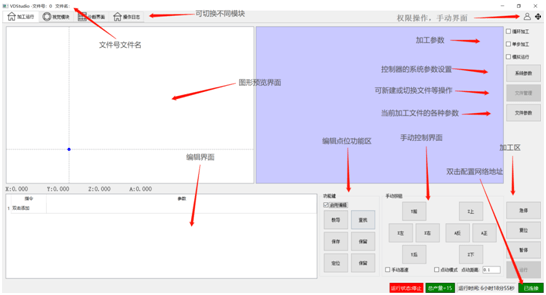

# Processing operation

The processing operation interface is used to edit processing files, modify processing parameters, and select processing programs. The parameter settings of the controller, including system parameters, file parameters, file management and other functions, are all in the processing operation interface.

System setting: The parameters used as a system are the same for any file, such as the parameters corresponding to the mechanical structure (motor characteristics, etc.), or some basic system configurations (port configuration) and other parameters that have nothing to do with the processed product.

File parameters: For different processed products, different processing speeds (trajectory speeds), different processing times, and different glue switching times may be required, which lead to different parameters for different processed products. Classify this type of parameters as file parameters. Therefore, the location of the parameter can be found according to the characteristics of the parameter.

During monitor operation, monitor mode or edit mode can be set. You can check "Start Editing" to switch modes.

Monitoring mode: It can only monitor the processing, but cannot modify the processing point. Monitor mode has a gray background:

Edit mode: You can edit the processing point. For safety reasons, the external signal is invalid in this state. Edit mode has a white background:

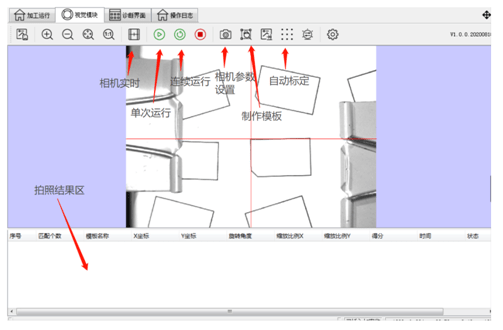

# Vision module

The vision module interface is used to set the camera, perform nine-point calibration, make visual templates, monitor camera data, etc. Visual module interface.

# Diagnosis

The diagnostic interface is used to monitor the input and output ports and view the program version number:

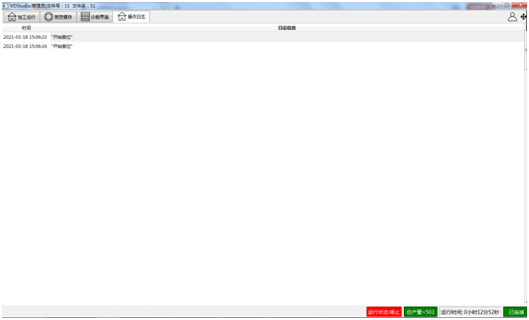

#Operation log

The operation log interface is used to view the operation process and obtain historical alarm information.

Scan the QR code to read on your phone