Applications:Furniture Industry

Keywords:panel furniture

Related products:

With the gradual disappearance of the demographic dividend and rising labor costs, the furniture industry to build a new manufacturing system with intelligence, digitalization, robotization as the fundamental characteristics of the development trend.

In the whole furniture manufacturing process, assembly is the follow-up link, and its human, material and financial resources consumption occupies a large proportion in the whole process of product manufacturing. Robots can be used to assemble parts or components of cabinets, chairs, wooden door frames, etc., effectively improving assembly efficiency and assembly precision.

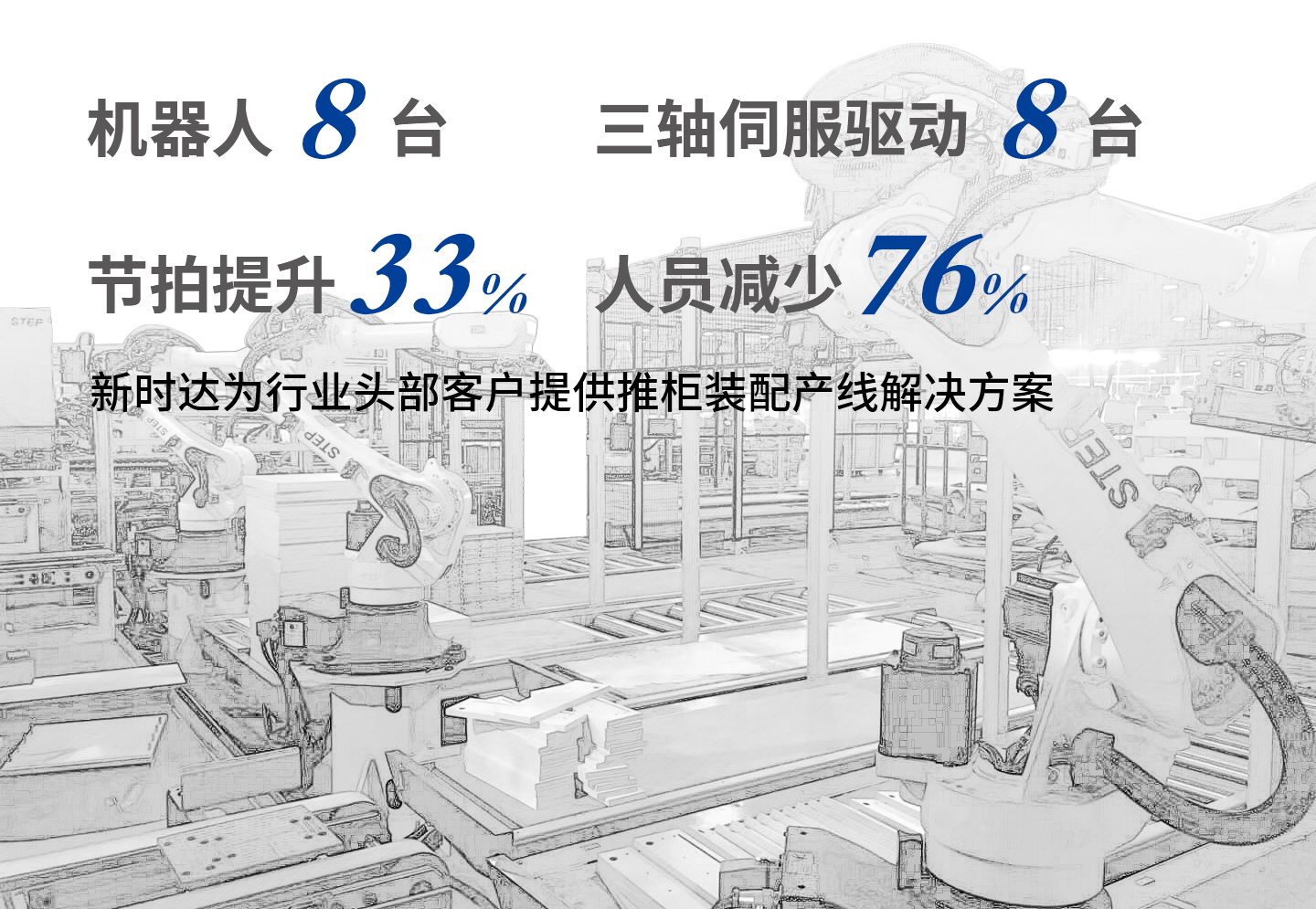

Focusing on the common problems in the transformation and upgrading of traditional furniture industry, relying on years of hard core strength in robotics and vision technology, NewSky is the first in the industry to launch intelligent assembly line solutions for panel furniture push cabinets, which can reduce manual intervention in production lines, carry out reasonable planning scheduling and quality monitoring, and quickly improve the level of intelligent manufacturing in the whole industry.

Our push cabinet assembly solution can be customized according to customer's scale, site, production process and investment capital, and has brought excellent benefits to customers.

Industry Pain Points

In today's home furnishings, the material of furniture is more often made of man-made boards in addition to the use of solid wood, connected using hardware, and furniture of this material is commonly known as panel furniture. Panel push cabinet structure mainly consists of side panels, pull stops, drawers and other parts.

The traditional assembly process of the push cabinet assembly line is mainly manual, with a low degree of automation and the following problems:

· Multi-species, small-lot, multi-combination form, low efficiency of line change and assembly;

· Product quality cannot be monitored;

· There is an imbalance in the rhythm between processes, and there is a wait for operations.

Program Highlights

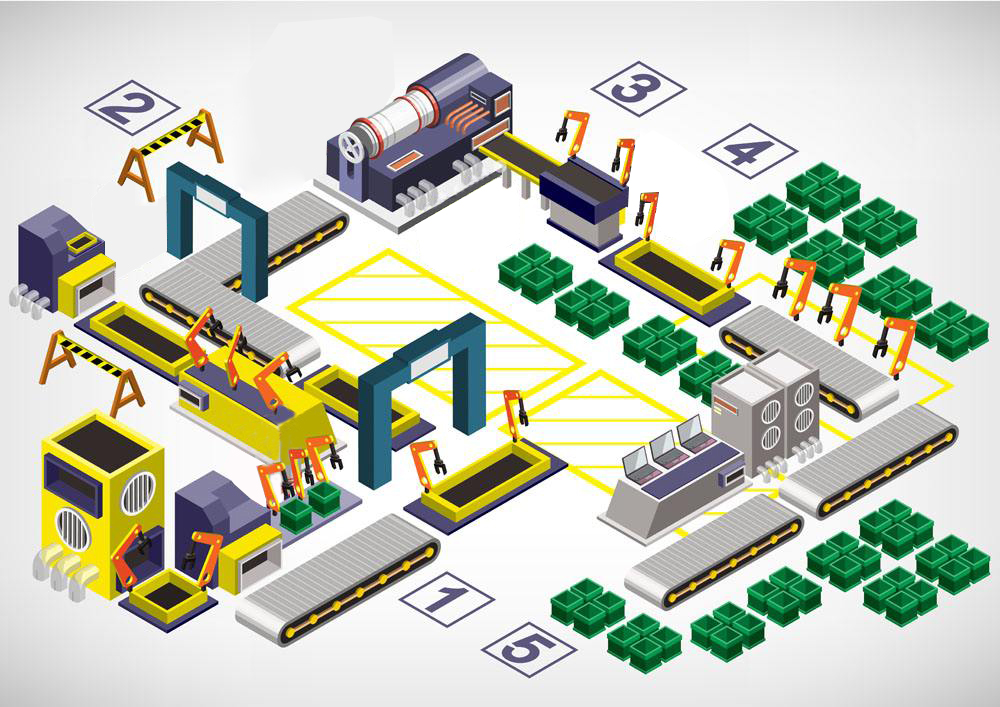

According to the assembly process of push cabinets - drawer assembly and plate pressing pin process, we split it into several automated equipment units to implement in pieces, and finally, we can also add the automated packaging link, and the whole process is laid out with the new Sida robot for loading and unloading, palletizing operation.

1// Standardized and modularized design

A large number of modular and standardized designs, for example, in drawer fitting and rail installation, they are equipped with standardized automatic tightening system and gluing mechanism respectively, which can solve various process requirements; automatic supply and press pin system adopts modularized combination design, so as to have horizontal press pin and vertical press pin functions; through the robot with 3D vision function, it can automatically identify the incoming material status of products and realize automatic grasping and positioning, etc. In the production management system, it is possible to change models with one key or switch models automatically according to orders; the back-end packaging line is fully automated.

2// Flexible production method and flexibility

According to the needs of users each equipment unit can be produced independently or the whole line can be produced together, through flexible production methods to face the push cabinet parts are the same, the overall structure of the products with large differences. In the intelligent production line solution for push cabinets, the unitized operation mode is used to realize that different types of parts can be produced separately without affecting the whole production line. When needed, the parts produced by different unit modules can also be transported to the main line through the conveyor line to achieve efficient production of the whole line.

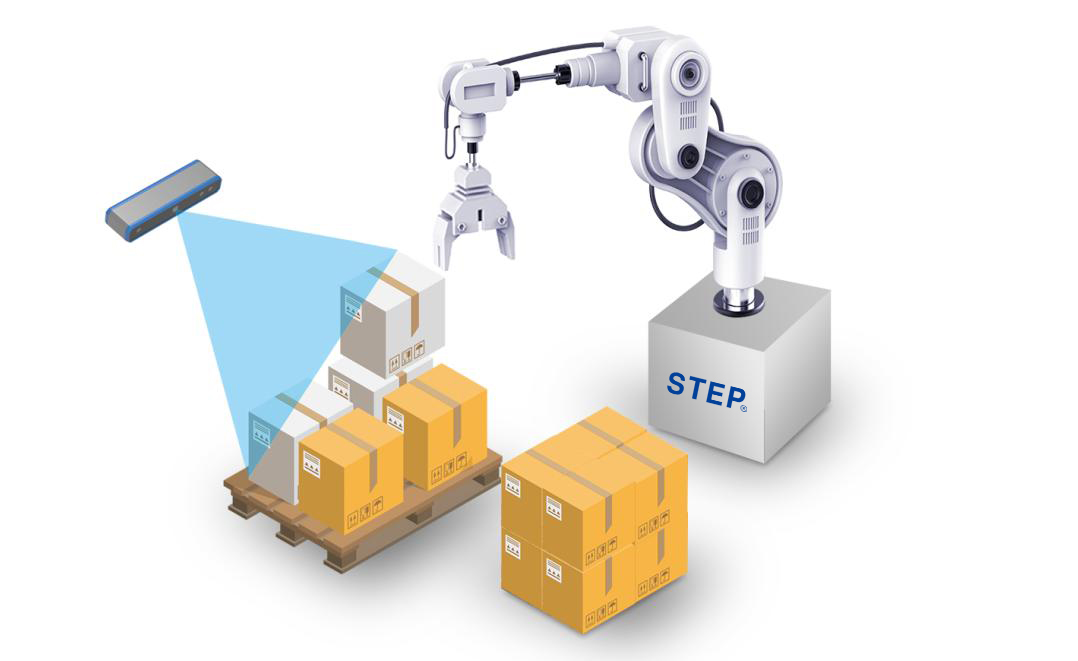

3// Large-scale application of vision technology

With the mass application of 2D/3D machine vision technology, the machine can automatically identify mixed or incorrect incoming material in the process of automatic sheet loading. When the incoming material is offset, the offset can also be compensated automatically by the robot vision algorithm.

4// Quality monitoring

Use MES system to realize the digitization of production process, realize the data record and quality monitoring of the whole process of pushing cabinet assembly, improve the efficiency of pushing cabinet production and product quality.

Benefit Embodiment

The intelligent assembly line solution for panel furniture push cabinets aims to create an Industry 4.0 benchmark production line for the furniture industry. Without increasing the overall layout size, both the entire production line with quality control system, production management system, product traceability system and flexible production, making the user brand competitiveness and production efficiency significantly improved and production costs significantly reduced.