Applications:Tire and rubber industry

Keywords:Inverter application cases

Related products:

Project NameProject Name:Jiatong Hefei Plant B vulcanizing workshop Jing Yuan vulcanizing machine F01-F05 hydraulic station.Jiatong Hefei Plant B vulcanizing workshop Jing Yuan vulcanizing machine F01-F05 hydraulic station.

Reason for transformationReason for transformation:Vulcanizing machine hydraulic station due to frequent work start and stop, resulting in frequent damage to the contactor (soft start), the motor monthly average burned 3; at the same time, mechanical shock and noise are larger, the life of mechanical parts are relatively reduced, the maintenance costs are higher; energy saving and emission reduction.Vulcanizing machine hydraulic station due to frequent work start and stop, resulting in frequent damage to the contactor (soft start), the motor monthly average burned 3; at the same time, mechanical shock and noise are larger, the life of mechanical parts are relatively reduced, the maintenance costs are higher; energy saving and emission reduction.

Remodeling methodRemodeling method:Replacement of the contactor solution with the new Timex ME500-4T 0037 inverter.Replacement of the contactor solution with the new Timex ME500-4T 0037 inverter.

Modification principleModification principle:Soft start and soft stop of the inverter, closed-loop feedback control, reduce the motor idling energy consumption.Soft start and soft stop of the inverter, closed-loop feedback control, reduce the motor idling energy consumption.

Remodeling timeRemodeling time:2 hours.2 hours.

Put into operationPut into operation:May 15, 2014.

Remodeling process

Keeping the original control system circuit unchanged, the contactor of the hydraulic station of the vulcanizer is replaced by a frequency converter, and the start/stop signal given by the system PLC is directly connected to the frequency converter to control the frequency converter start/stop (eliminating the intermediate relay), while the pressure signal of the hydraulic station is connected to the analog port of the frequency converter to make the pressure signal feedback closed-loop control, and the speed of the frequency converter is controlled by the pressure signal.Keeping the original control system circuit unchanged, the contactor of the hydraulic station of the vulcanizer is replaced by a frequency converter, and the start/stop signal given by the system PLC is directly connected to the frequency converter to control the frequency converter start/stop (eliminating the intermediate relay), while the pressure signal of the hydraulic station is connected to the analog port of the frequency converter to make the pressure signal feedback closed-loop control, and the speed of the frequency converter is controlled by the pressure signal.

Working ProcessWorking Process

After the PLC gives the start signal, the inverter starts, the pressure of the hydraulic station rises rapidly to the set value, providing hydraulic power to the hydraulic device to open or close the mold; when the action of opening and closing the mold is completed, the voltage (or current) output of the pressure sensor decreases, the frequency of the inverter decreases to low frequency, the motor runs at low speed, and the pressure of the hydraulic station is kept at the set value at this time; when the hydraulic device starts to act, the flow of the hydraulic station When the hydraulic device starts to act, the hydraulic station flow increases and the pressure decreases, the pressure sensor voltage (or current) output increases, the frequency of the inverter increases rapidly to the quota frequency, the motor runs fast and provides the required pressure to the hydraulic station; so on and so forth, when the PLC gives a stop signal at the end of a cycle, the inverter stops and is in the standby state, waiting for the next work cycle to start.After the PLC gives the start signal, the inverter starts, the pressure of the hydraulic station rises rapidly to the set value, providing hydraulic power to the hydraulic device to open or close the mold; when the action of opening and closing the mold is completed, the voltage (or current) output of the pressure sensor decreases, the frequency of the inverter decreases to low frequency, the motor runs at low speed, and the pressure of the hydraulic station is kept at the set value at this time; when the hydraulic device starts to act, the flow of the hydraulic station When the hydraulic device starts to act, the hydraulic station flow increases and the pressure decreases, the pressure sensor voltage (or current) output increases, the frequency of the inverter increases rapidly to the quota frequency, the motor runs fast and provides the required pressure to the hydraulic station; so on and so forth, when the PLC gives a stop signal at the end of a cycle, the inverter stops and is in the standby state, waiting for the next work cycle to start.

Remodeling effect

1)Stable and reliable performance. Since it was put into operation, the inverter has been working stably. In summer, the working environment temperature of the hydraulic station of vulcanizer is close to 50℃, ME500 breaks the bottleneck that conventional inverter cannot work normally in high temperature and dusty environment without any failure, thus ensuring continuous and uninterrupted production and improving output.

2) Lower maintenance cost. Because the inverter works stably and reliably, there is no downtime and device damage during production, so there is no need to stop and replace the damaged contactor (or soft start) and other spare parts, and only dust removal, tightening screws and other routine maintenance work on the inverter during downtime maintenance, saving human resources and spare parts costs, while ensuring the continuity of production and improving output.

(3) Reduce the impact, extend the service life of mechanical parts and motors, and reduce the purchase cost of spare parts and other spare parts. Frequent direct start or stop of the equipment will produce a strong mechanical shock, resulting in the loss of mechanical parts too fast or even damage, the motor will also be 6-10 times the impact of the starting current, resulting in the aging of the coil and thus shorten the life, burned, and the soft start and soft stop function of the frequency converter, can ensure that the equipment in the process of starting and stopping work smoothly, and when the hydraulic station in the absence of hydraulic output, frequency low frequency working state motor low speed operation Also reduces the mechanical wear and tear of the equipment, thus reducing the mechanical shock, extending the service life of mechanical parts and motors, reducing the purchase cost of spare parts, etc.

(4) Energy saving. Before the equipment transformation, the hydraulic station installed electricity meter statistics to calculate the cost of electrical energy of a single tire; according to the meter measurement of electrical energy cost statistics can be seen, the use of inverters there is still a lot of room for energy saving:.

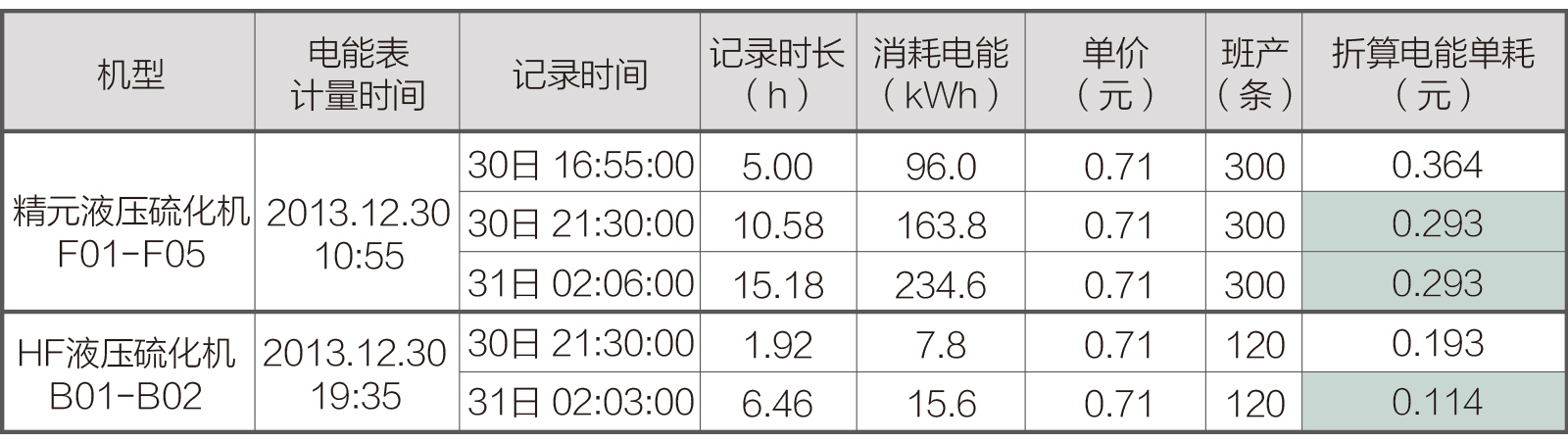

Table 1 Comparison of electrical energy consumption between Seiko's hydraulic vulcanizer and HF vulcanizerTable 1 Comparison of electrical energy consumption between Seiko's hydraulic vulcanizer and HF vulcanizer

Note:

① Sunrex vulcanizer F01-F05 pump station was enabled with one 37kW and 22kW motor each.

② The installed single-phase power meter has an initial value of about 0.02kWh, resulting in a larger value for the 1st time.

③ Calculate the value of consumed electric energy: single-phase energy meter reading value × 3 × 20 (100:5 transformer).

From the statistical results in Table 1, we can calculate that the average power consumption of each tire of Jingyuan hydraulic curing presses F01-F05 before the modification is:

H unit consumption = (0.364 + 0.293 + 0.293 + 0.284) ÷ 4 = 0.3085 yuanH unit consumption = (0.364 + 0.293 + 0.293 + 0.284) ÷ 4 = 0.3085 yuan

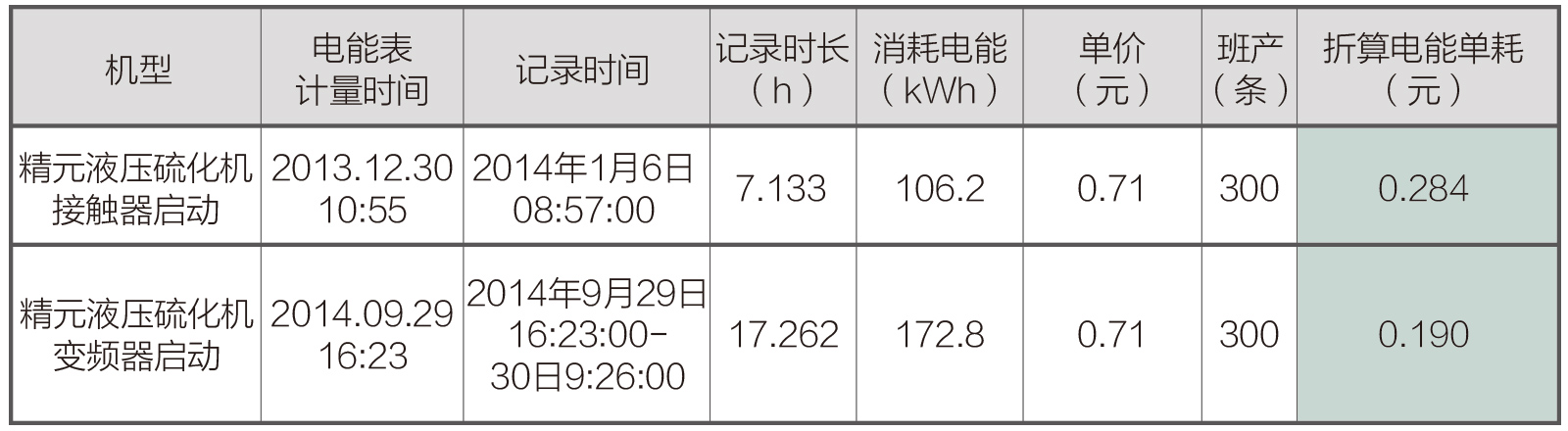

Table 2 Comparison of electric energy consumption of Seiko's hydraulic vulcanizing pressTable 2 Comparison of electric energy consumption of Seiko's hydraulic vulcanizing press

Note:

① Sunrex vulcanizer F01-F05 pump station was enabled with one 37kW and 22kW motor each.

② The installed single-phase power meter has an initial value of about 0.02kWh, resulting in a larger value for the 1st time.

③ Calculate the value of consumed electric energy: single-phase energy meter reading value × 3 × 20 (100:5 transformer).

According to the statistics in Table 2, the power consumption of each tire after frequency conversion is: H unit consumption = 0.19 Yuan

i.e.:Saving S per tire produced = 0.3085 - 0.19 = $0.1185

The number of tires produced per day is: Daily output = C output × B shift = 300 × 3= 900 bars

Monthly savings S month = S single province × day production × number of days per month = 0.1185 × 900 × 30= 3199.5

According to 300 days of continuous production time, 3 shifts per day, 300 tires per shift, i.e., the renovation cost can be recovered by saving electricity cost in 1 year.

Reformation conclusion

After the modification, the operation of the equipment is stable, the control is accurate and smooth, the energy-saving effect is obvious, the maintenance cost and the noise of the equipment are obviously reduced, and it is suggested that all the hydraulic stations of the vulcanizing machine are transformed by frequency conversion.