Applications:Coal mining industry

Keywords:Inverter application cases

Related products:

The outbreak of the new crown epidemic this year has brought great inconvenience to the production economy everywhere. The commissioning of 3 sets of high voltage inverters for main shaft belt in a coal mine in Ordos scheduled for February 15 was also affected, which would affect the heating demand in some northern areas if not put into production in time. Combined with the understanding of the actual situation on site and the consideration of ease-of-use of NewSky products, we decided to adopt the alternate solution - remote commissioning.

1、The situation of coal mine main shaft belt system

Original system configuration: Belt transport capacity:1500t/h adhesive tape:Width 1400mm, strength ST3150, wire rope core Belt speed:3.15m/s Transport length:1110m Inclination:+16° Drive power:3×710kW, inverter drive Main motor voltage:6000V upgrade section:The drive power is increased from 3×710kW to 3×1000kW The upgrade direction:Expanded capacity, motor and inverter system expansion, upgraded belt transport capacity is expected to reach 2000t/h

2、Site control program confirmation

① Original system situation. The original system at this coal mine site also uses high-voltage inverter drive. As the production capacity increases, the original system can no longer meet the production and transportation needs, and the original system uses separate control scheme, with three inverters given separate running signals, and the torque balance is achieved by manually adjusting the running frequency.

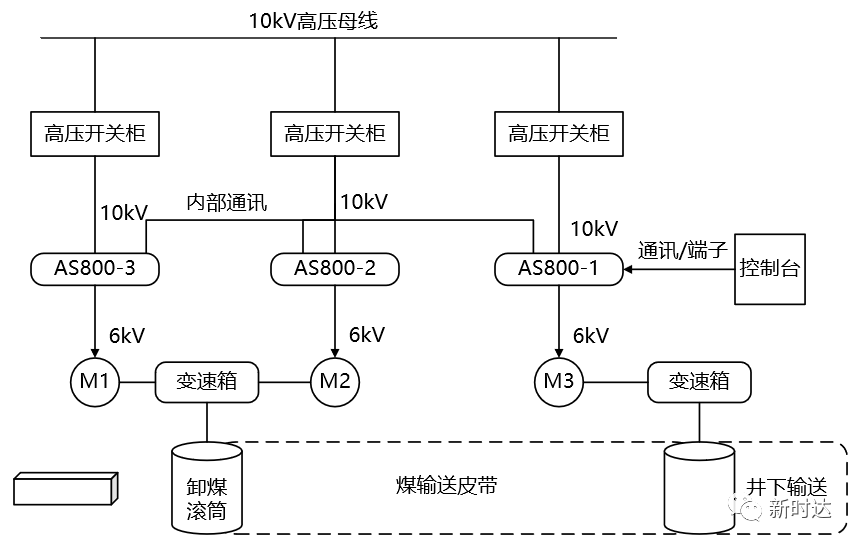

② Transformation target. The new Timeless inverter adopts master-slave control droop function, the software automatically measures the output torque, automatic power balancing, and the output voltage and current of the slave machine are consistent with the host machine. Really realize the inverter automatic load balancing. The system control scheme is as follows Figure 1.

Figure 1 - Master-slave control system diagram

3、Guidance on field wiring

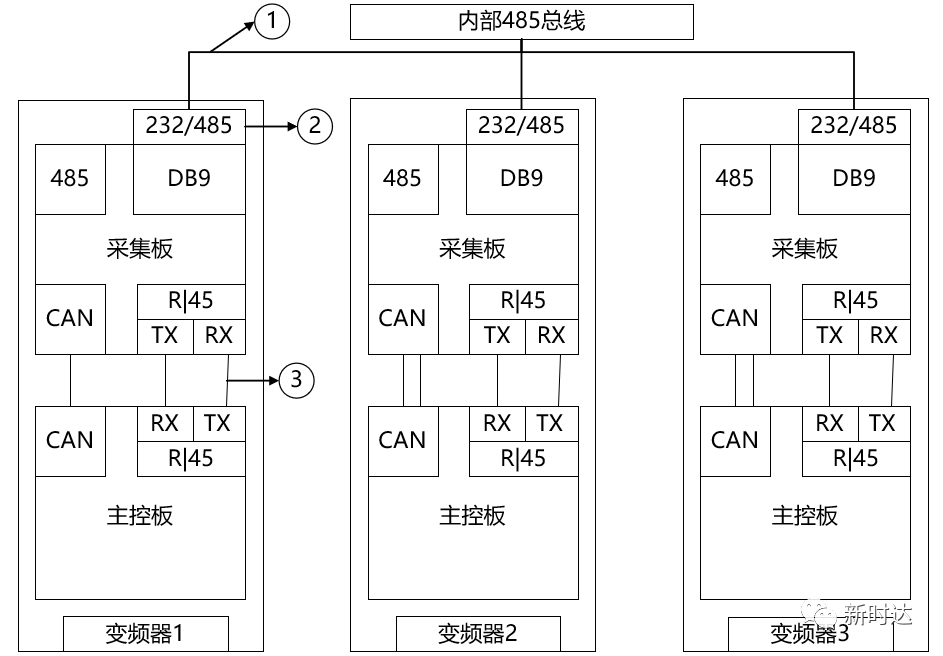

① Internal wiring of the inverter. Mainly the internal communication line connection line of the inverter, through remote guidance, the communication system required for commissioning was quickly completed. The internal communication connection of the inverter is guided in Figure 2 below.

Figure 2 - Internal communication connection of inverter

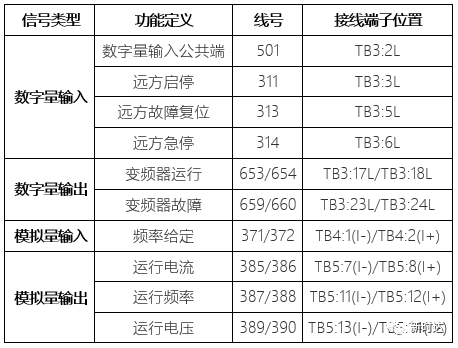

② External control line connection. Drawings to extract the user needs to control the signal, list the signal in accordance with the signal type marked with the corresponding line number and wiring position corresponding to the terminal number, microsoft video guide the user to complete the control section wiring in accordance with Table 1.

Table 1 - Inverter external control wiring

4、No-load test run

① High voltage side wiring check. WeChat video instructs users to confirm and check the wiring position of the inlet and outlet lines of the inverter before the trial run.

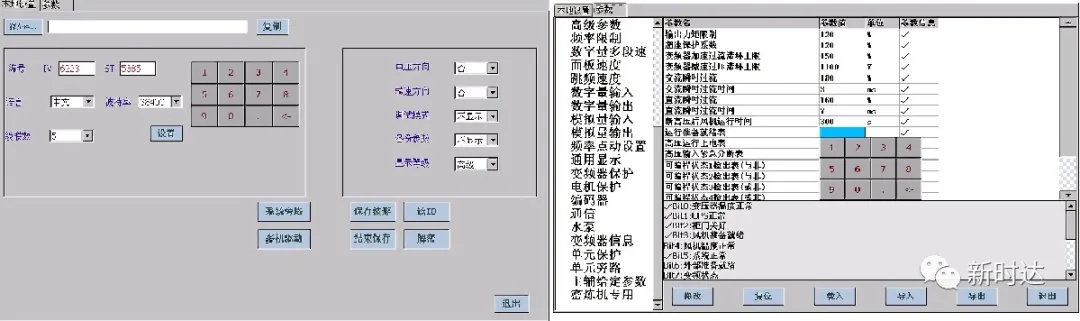

② Inverter parameter setting check. Most of the parameters of the inverter have been cured, and the parameters of master-slave control have been cured to the multi-machine drive module, so the check is relatively smooth.

Figure 3 - Inverter multi-drive parameter module Figure 4 - Inverter parameter setting interface

③ Confirmation of control logic

- Operation method:After the operator console gives the host a start/stop command, the host executes the start/stop while the host controls the start/stop of slave 1 and slave 2 through internal communication.

- Fault handling mode: Any 1 of the 3 inverters will report a fault stop, and the 3 inverters will make a fault judgment through internal communication and block the emergency stop at the same time.

Emergency stop processing mode: Any 1 of the 3 inverters will stop manually, and the 3 inverters will make emergency stop judgment through internal communication, and block the emergency stop at the same time.

④ No-load test run problems encountered and solutions

Host fault: the first time the host high voltage power supply reported all power units uplink fiber fault, check found that the master side fiber plugging when the upstream and downstream communication plugging reversed, after correction to solve the problem.

Slave 1 fault: When the master and slave control are linked, slave 1 reports unit blocking fault, check the internal communication cable of the inverter, replace it with shielded wire and increase grounding measures to solve the problem.

5、Test run with load

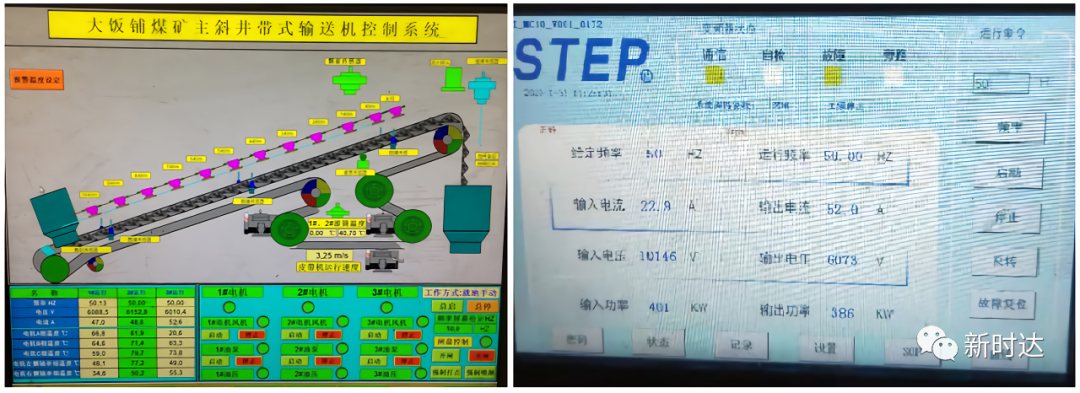

The user can execute the belt load test before production by using the coal produced in the underground stock part. After the user console sends the start command to the main machine directly, the 3 inverters drive the main shaft conveyor to start to slowly transport the coal produced underground to the discharge area smoothly, and the belt load test run is successful.

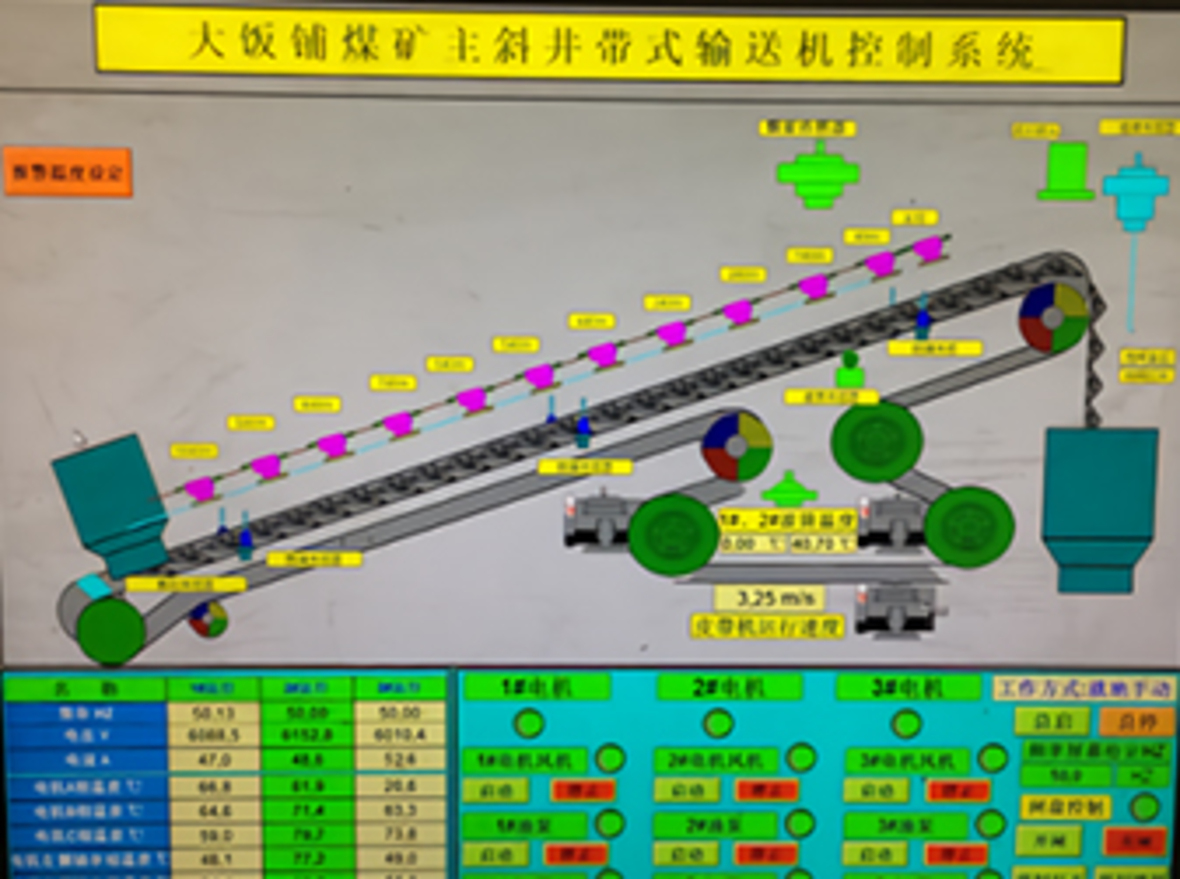

Figure 5 - User transport belt machine operation console Figure 6 - Inverter mainframe operation interface

6、Officially put into operation

Coal belongs to the basic guarantee material to ensure people's livelihood. The coal mine responded to the national call to resume production in time during the difficult period of the epidemic, and the inverter was officially put into production operation.

Figure 7 - Inverter in normal operation Figure 8 - Inverter mainframe operation interface

Summary ① The application of constant torque output of the new Timeless high voltage inverter has realized automatic load balancing. According to the user's feedback, the original manual feeding method, the inverter output is uneven, often the slave machine is dragged to run in the power generation state, resulting in over-voltage alarm. The belt was stretched and scrapped after 1-2 years of use due to uneven force. After the modification, automatic load balancing was realized, the belt life was greatly extended, and the danger of overpressure burning the brake unit of the slave machine was eliminated.

② The success of this WeChat video guidance commissioning verified the ease of use of NewSkytec high voltage inverter operation, and some of the inverter equipment shipped from the factory are now free of commissioning. In the future, NewSkytec high voltage inverter can realize network online debugging, online fault diagnosis and other functions to help the industrial control industry to be intelligent. A new chapter is written for remote service under special circumstances.