Applications:Drip molding machine

Keywords:Drip molding process

Related products:

Drop molding technology is to use the thermoplastic polymer material has the characteristic of variable state, that is, under certain conditions with viscous flow, but at room temperature can return to solid characteristics, and the use of appropriate methods and special tools inkjet, in its viscous flow state according to the requirements of molding into the designed form, and then curing at room temperature molding.

Relying on numerical control processing technology, New Shih Da Transportation Control has changed the link of manual dispensing in the drip molding process to automatic dispensing by machine, which has greatly improved the efficiency of production.

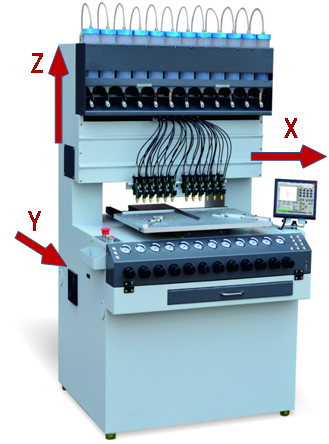

Figure 1 Drip molding machine

As shown in the figure, the drip molding machine adopts gantry design, which mainly consists of bed, operation and control system, X/Y/Z three-axis motion system (servo system driven ball screw drive), material supply module, and dispensing module.

The operation and control system mainly provides G code guide processing, motion trajectory planning, dispensing valve drip molding process control, HMI handheld touch and button control graphics processing flow and other functions.

The AC servo system of X/Y/Z three-axis motion system accepts the command information from the control system, and after power amplification and shaping processing, it is converted into linear displacement motion of the executive parts of the drip molding machine, whose performance will directly affect the accuracy and speed of the drip molding machine and other technical indicators, requiring good fast response performance, accurate and sensitive tracking of the digital command signal from the controller, and can faithfully execute the commands from the It is required to have good fast response performance, accurate and sensitive tracking of digital command signals from the controller, and faithful execution of commands from the upper controller to improve the dynamic following characteristics and static tracking accuracy of the system.

The drip molding machine relies on the X/Y/Z three-axis motion system to bring the PVC paste dispensing needle to the designated position of the drip mold, and controls the amount of dispensing by controlling the time of extruding paste resin and the speed of needle movement. To achieve a certain dispensing effect. The related operation flow is as follows:

Figure 2 Start-up process of drip molding machine

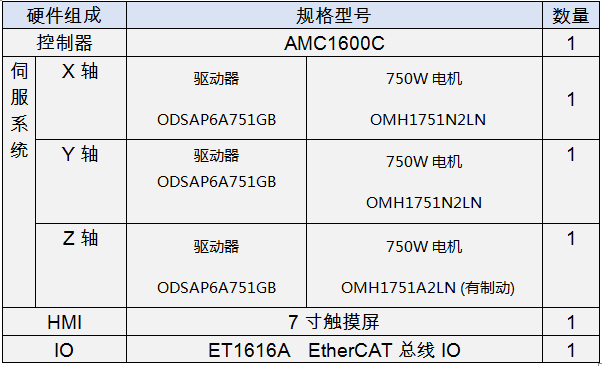

The system solution of NewSky Transport Control drip molding machine is mainly composed of motion controller, servo driver, servo motor, HMI, expansion IO, etc. The system topology is shown below:

Figure 3 Topology of Sinostar's transport control drip molding solution

The control core of this solution consists of AMC1600 motion controller and Sigriner (Sigriner) Ω6s-APR series pulse AC servo system. This solution supports G-code trajectory guide processing, 18-way dispensing valve drip molding process, and 36 processes external button control for fast switching processing.

The system configuration list is shown in the table below:

Application advantages of NewSky Transport Control plastic machine solution

#1 More dispensing valve control, support maximum 18 way dispensing valve, complete multi-recipe function, maximum support 36 groups of product processing.

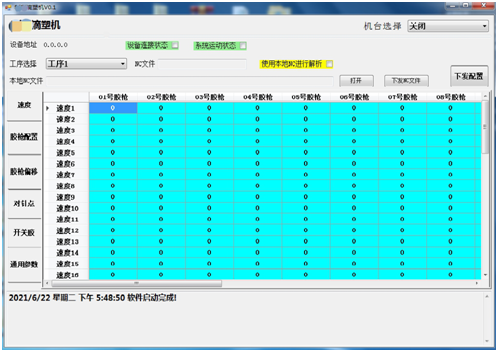

#2 Increase the computer upper computer online to network equipment settings for parameters and upload or download files, support the upper computer to collect equipment operation data.

Figure 4 The upper computer debugging interface

#3 Support handheld touch screen tuning and full key operation, processing G code and parameters support U disk import and export. Maximum convenience for the operator to debug.

Figure 5 HMI control interface

#4 Larger parsing cache support, up to 30,000 lines of G-code instructions for a single machining file.

#5 CNC powerful acceleration and speed profile planning to ensure high speed and smooth operation of the machine, 8%-10% more efficient than conventional models.

Figure 6 CNC speed planning

#6 Sigriner Singh Grenadier has customized a set of servo system parameters to match the plastic molding process after a long period of testing and summing up. The newly developed auto-tuning function of Ω6s-ARR series servo without debugging saves 90% of equipment debugging time. The processing results are shown below, which meet the ideal needs of customers.

Drip molding process and finished products:

Program Summary

The new Timeless O&C Omega 6 series AC servo system and AMC1600C motion controller products are the series of products developed by the central research institute of Timeless Group and Singhina team, which are widely used in general industrial control applications. The product is widely used in general industrial control applications.

It can successfully help users to solve many problems such as complex solutions and high maintenance cost, which reflects the high performance and high reliability of NewSky products, and is the value presentation of NewSky's insistence on innovation-driven and high-quality development. With the core of motion control and integration of related interface equipment, NewSky provides overall automation control solutions to meet the needs of customers in various industries to improve quality, expand production capacity and reduce costs.