One of the soft control features of the intelligent flexible platform driver: synchronous motor drive

- Views:

- Time of issue:2022-06-06 00:00

One of the soft control features of the intelligent flexible platform driver: synchronous motor drive

- Views:

- Time of issue:2022-06-06 00:00

STEP's new generation of EP/ET/EH intelligent flexible drivers has been launched for nearly a year, and the application features of its products have played an important role in many user sites. Starting today, we will introduce the firmware functions of the smart flexible driver in multiple phases, so that everyone can understand the new functions of the STEP driver.

As we all know, double carbon energy saving is one of the main directions of current industrial development. Customers are no longer satisfied with the application of traditional squirrel-cage three-phase asynchronous motors. Permanent magnet synchronous motors and synchronous reluctance motors with higher energy efficiency and higher control precision have become the first choice for many industries.

There are many problems when the original inverter directly controls the permanent magnet or reluctance motor. for example:

1. The counter electromotive force of the permanent magnet causes the motor to reverse;

2 The motor self-tuning cannot be completed, the motor crawls at low speed, and cannot reach the given frequency (cannot reach the speed);

3 The motor vibrates, howls, heats up, cannot operate normally, etc.

Therefore, the traditional inverter algorithm cannot control the operation of the synchronous motor well, and the synchronous motor is driven by the V/F control method, and the performance of the motor cannot be brought into play at all. STEP is a well-established elevator electric control complete set manufacturer. It has more than 20 years of experience in the application of synchronous motors in the elevator industry, and has long been familiar with it.

The parameters of the intelligent flexible drive in synchronous motor control fully reflect its product advantages. The reverse rotation of the synchronous motor is due to the fact that the permanent magnet is under the influence of the salient pole effect, because the magnetic pole position is uncertain, and the wrong current phase is input. Therefore, when starting up, the initial position of the magnetic pole must be estimated first, and the position of the magnetic pole should be detected.

Internal parameters of the smart flexible driver:

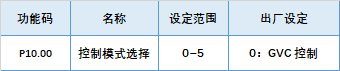

This function is used to set the control operation mode of the inverter:

0: GVC control

Suitable for most applications, suitable for synchronous motors, asynchronous motors and synchronous reluctance motors.

1: SVC control

Sensorless vector control, suitable for synchronous motors and asynchronous motors.

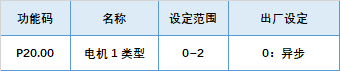

Optional motor type:

0: asynchronous motor

1: synchronous motor

2: Reluctance motor

Moreover, the driver can support the second motor drive, which is widely used in logistics shuttles, stackers and other occasions.

0: no judgment

The ability to start without load requires a relatively long acceleration time.

1: DC injection start

Inject DC current to (P15.05*motor rated current) incrementally, and drag the motor magnetic pole to the excitation direction.

2: Pulse voltage injection start

Inject voltage pulses for initial magnetic pole determination.

Through the above parameter settings, in conjunction with the motor self-tuning, the synchronous motor can be driven to start well, and the characteristics of the permanent magnet synchronous motor and synchronous reluctance can be brought into play. Therefore, when someone claims that his inverter can also drive synchronous motors, he can check his user manual parameter table to see if there are any of the above parameters. If not, driving synchronous motors will not be able to avoid some abnormal phenomena described earlier in this article, and it will not be possible to drive synchronous motors well and play their best energy efficiency level.

Scan the QR code to read on your phone