Leading market segments | STEP builds a thermos cup smart factory to help Yongkang build a world advanced manufacturing base

- Views:

- Time of issue:2022-07-18 00:00

Leading market segments | STEP builds a thermos cup smart factory to help Yongkang build a world advanced manufacturing base

- Views:

- Time of issue:2022-07-18 00:00

Manufacturing power, STEP robots are in action. In Yongkang, Zhejiang, STEP and its partners have jointly written a new chapter of "surrounding industrial clusters, prospering the county economy, and building a world advanced manufacturing base" .

Zhejiang, the leader of China's county economy; Yongkang, the veritable "capital of cups", produces 70% of China's thermos cups, and the local government is committed to "building an advanced manufacturing base in China and the world." The leading company in the thermos cup industry in Yongkang pursues the strategy of "well-known brand OEM + own brand", attaches great importance to product quality, and constantly explores advanced manufacturing processes and technologies in the entire production process. In terms of intelligent manufacturing, it is willing to invest and change; brand positioning Low-end enterprises focus on cost control, and have urgent needs for automation of thermos cup processing processes such as water rising, lifting, and polishing.

STEP, which has mastered the core technology of robots, implemented the strategy of "deep cultivation and subdivision" , and took the lead in launching the metalworking line intelligent manufacturing solution that users are most concerned about in the Yongkang vacuum cup industry cluster.

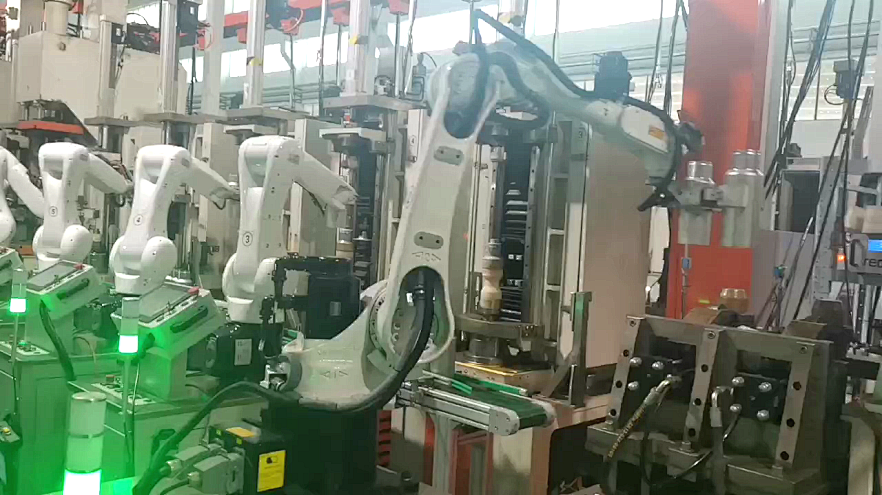

This solution uses STEPSD7/900, SA6/1400, SR20/1700 and other types of robots , with flexible grippers, to achieve non-destructive handling of thermos cups at different positions, reduce manual intervention as a whole, and improve product yield to more than 99%. Effectively reduce steel loss.

On the metalworking line of a thermos cup head enterprise in Yongkang, dozens of STEP robots are running according to the program, and the raw steel coils on the conveyor belt are accurately placed on the operation table of the next process. In this way, a semi-finished product can be produced every 6 seconds.

The person in charge of a local thermos cup company said, "Originally a production line required 18 workers, but now it only needs 2. The fully automated production line ensures the consistency of product quality and improves production efficiency. After calculation, production efficiency can be improved. About 37%."

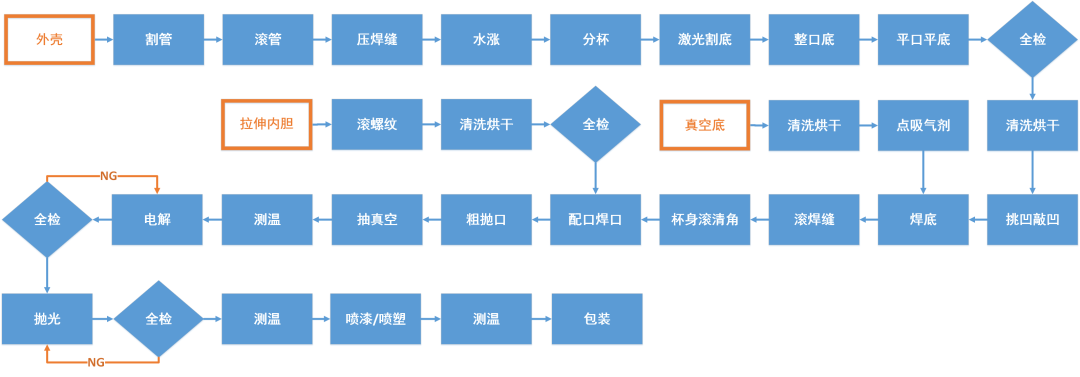

The metalworking line that has been implemented so far is only a link in the intelligent production of thermos cups. There are more than 20 processes in the whole technological process for the outer shell, inner liner, and vacuum bottom of the thermos cup.

In the future, STEP will join hands with partners to provide a variety of robot application options for production lines such as thermos cup welding, stretching, polishing, and packaging, provide enterprises with whole-plant planning services, implement turnkey production line projects, and continue to improve local thermos cups The level of intelligent manufacturing in the industrial agglomeration area helps Yongkang build a world advanced manufacturing base.

Scan the QR code to read on your phone