STEP robot was selected as an excellent manufacturing case in 2022 by the Ministry of Industry and Information Technology

- Views:

- Time of issue:2023-01-03 03:03

STEP robot was selected as an excellent manufacturing case in 2022 by the Ministry of Industry and Information Technology

- Views:

- Time of issue:2023-01-03 03:03

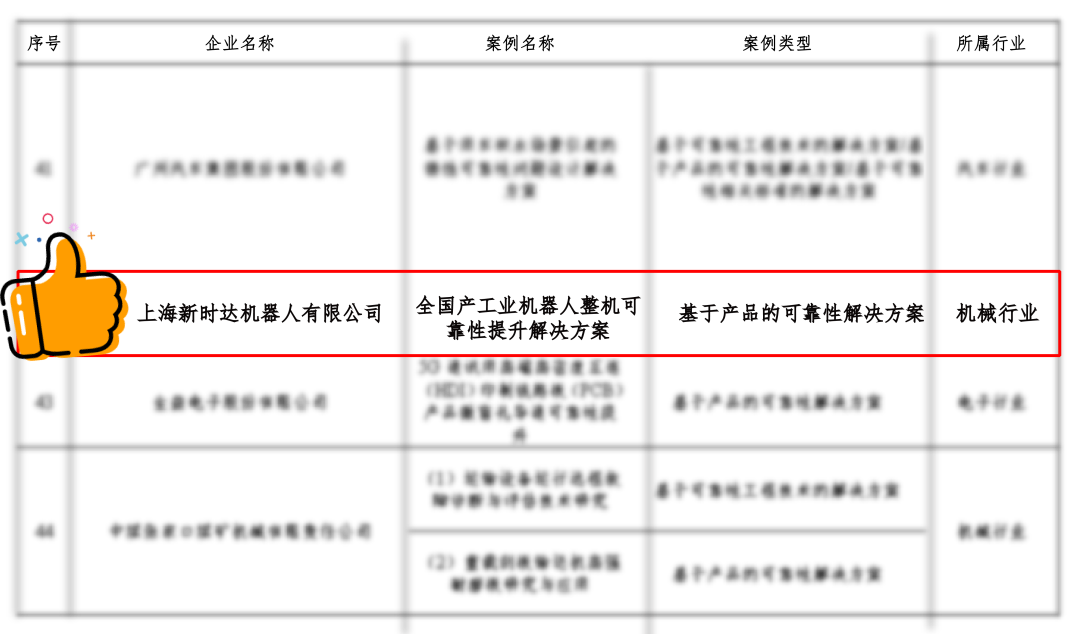

On December 12, 2022, the results of the "Selection of Excellent Cases of Manufacturing Reliability Improvement in 2022" entrusted by the Science and Technology Department of the Ministry of Industry and Information Technology, jointly with various local authorities and relevant industry associations, were released, and Shanghai STEP Robot Co. , Ltd. declared The "National Industrial Robot Machine Reliability Improvement Solution" was successfully selected, which is the only excellent case related to the robot itself.

The selection of excellent cases of reliability improvement in the national manufacturing industry mainly focuses on key core products in key industries such as machinery, electronics, and automobiles, and collects a number of outstanding projects around reliability engineering technology, reliability management, quality and reliability tools, etc. The reliability level of national manufacturing products helps to improve product quality and enterprises to improve quality and efficiency.

As an innovation-driven enterprise, STEP has been deeply involved in the field of industrial robots for a long time. Through the in-depth implementation of the strategy of "matching imports and surpassing imports", the performance of robot products has been comparable to that of international first-line brands. At the same time, STEP also attaches great importance to the reliability design and testing of industrial robots . Technology, committed to forming a distribution system from the whole machine to the reliability indicators of each core component, and mastering the forward design method of robots for multi-scenario applications.

This time, based on the background and existing experience of accelerating the localization of the robot industry, STEP proposed a solution to improve the reliability of domestically produced robots from several dimensions such as structure, hardware, software, testing, and quality assurance. Through the implementation of this project, domestic industrial robots can be improved and enhanced in terms of core components and overall machine reliability, solving problems such as dependence on imports of high-end components, low quality and reliability of domestic robots, and low substitution rate of domestic chips. Realize the national production of mid-to-high-end core component products, improve the reliability of domestically produced robots, and greatly increase the MTBF of industrial robots.

This project is also of great promotion significance in the industry, especially if the core parts can be replaced by localization of upstream parts, it will not only solve the supply chain security problem, but also significantly reduce the application cost of industrial robots, shorten the delivery time, and further promote The application of industrial robots improves the level of intelligent manufacturing.

Scan the QR code to read on your phone