STEP Motion Control won the CMCD annual award in the field of motion control, ending 2022 perfectly!

- Views:

- Time of issue:2023-01-03 00:00

STEP Motion Control won the CMCD annual award in the field of motion control, ending 2022 perfectly!

- Views:

- Time of issue:2023-01-03 00:00

On December 20, 2022, the "2022 China Motion Control/Direct Drive Technology Industry Development Summit " and award ceremony hosted by Transmission(Chuan Dong) Network will be held as scheduled. The theme of the forum is "meet your confidant, see yourself", bringing together 500+ industries people to discuss the direction and future of the industry. Dr. Xinzhong Ding, Product R&D Director of STEP , was invited to attend this forum and delivered a keynote speech entitled "Smart Drive, Control at Your Heart - Ω6 Direct Drive Servo System". At the same time, STEP won the most competitive brand award in the field of CMCD motion control , STEP The SC30 PAC product won the award for innovative products , and Zhishan Zhikong, a subsidiary of STEP , won the CMCD Motion Control Field Customer Satisfaction Brand Award .

Driven by wisdom, control as you like! Play with Ω6 direct drive servo system

Dr. Ding Xinzhong of STEP pointed out that STEP operation control can provide core components such as control, servo and vision, as well as turnkey solutions for operation control and industrial transmission, and serves customers in 3C, semiconductor, laser, dispensing, EDM, digital printing, etc. industry. As a key product, Ω6 direct drive servo system is innovative and leading in terms of industrial design, application support, performance and function construction.

The Ω6 direct-drive servo system can be described as an "all-rounder", which supports the use of voice coil motors, linear motors, DDR motors and linear gantry . In addition, it also has a "hard core" performance.

√ The high-speed IO response time is within 1μs , which can easily meet the needs of flying shots and probes

√ The encoder resolution supports up to 32bit , which can calmly meet the requirements of sub-micron level control accuracy

√ The refresh frequency of the current loop reaches 1Mhz , effectively reducing the digital sampling and control delay

√ Strong power, support 115% continuous overload, 350% instantaneous overload, easy to deal with frequent start-stop/acceleration/deceleration occasions of direct drive

More than ten years of accumulation of direct-drive technology and continuous iterative updates of products have made the Ω6 direct-drive servo system quite complete in terms of functionality and intimate user experience, helping users improve the overall value of the equipment.

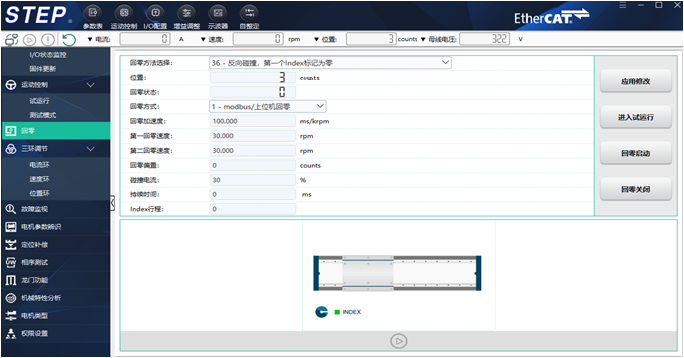

The Ω6 direct drive servo system has a new generation of micro-motion commutation function to learn the initial angle of the mover. With the support of the new generation algorithm, the moving range of the mover is within 0.5mm ; the fully automatic Hall commutation function solves the problem of debugging personnel. The oscilloscope observes the phase, judges the direction and changes the physical wiring; the position comparison output (flying shot), a single servo has 8 position comparison points, which are mapped to 6 general-purpose IOs, and multiple servos can also realize parallel flying . It supports up to 256 position comparison points. Because the FPGA is used to realize the flying shooting, the stability of the flying shooting is also guaranteed; the more advanced adaptive flying shooting does not need to set the parameters of the flying shooting delay, and can meet the needs of different system speeds. Accurate flying shooting, the accuracy is increased by 90% , and the mean square error is reduced by 90% ; the high-precision positioning compensation function can import the error compensation data table with one key; on the basis of supporting 35 kinds of CiA402 standard zero return methods, a Three original collision zero return methods meet the needs of multi-axis and small space working conditions in the semiconductor and other industries; the use of nonlinear control greatly reduces position tracking errors, reduces positioning time, and improves work efficiency.

△ Collision return to zero function

Of course, the convenience of debugging is also a highlight of STEP's full range of servo products, which have been well inherited and innovated in the Ω6 direct drive servo system. At present, the Ω6 direct drive servo system provides two self-tuning methods. The one-button self-tuning can automatically identify the motor’s load inertia ratio, friction model parameters, and low-frequency vibration frequency, etc., and automatically configure the current loop/speed loop. /The parameters of the position loop controller; while the online gain adjustment will automatically adjust the load inertia ratio, adaptive notch and rigidity value according to the working conditions.

Gantry is more and more widely used on some large machines. For this reason, the Ω6 direct drive servo system is designed in two dimensions. On the one hand, the RT HyperGS real-time synchronization bus is independently developed, and the real-time data exchange and control timing synchronization of the two servo drives of the master and slave axes are realized through a single crossover network cable. (synchronous jitter < 0.1μs), on the other hand, a gantry coupling control strategy is formulated to realize the adjustment of synchronous rigidity through the setting of the coupling coefficient, and adapt to mechanical equipment with different assembly precision.

At present, the Ω6 direct drive servo system is playing an enabling role in various industrial equipment such as die bonding, glue dispensing, laser cutting, panel inspection, and LED light splitting, forming many typical application scenarios, and its product specifications are also improving day by day. The released products include Pulse type and EtherCAT bus type 200V , 3.2A to 20.8A , a total of more than 20 specifications, 400V products will meet users in 2023.

Won the CMCD motion control field award

CMCD is the annual award with the most corporate participation and industry influence in the field of motion control. It was selected by experts from China Motion Control Industry Alliance, industry organizations and professional media after 2 months of comprehensive selection. In 2022, STEP won this honor, which is a strong proof of the brand's comprehensive strength in the field of motion control, and once again shows that its motion control products have been continuously recognized by industry users in terms of quality, innovation, service, and cost performance .

STEP will continue to uphold the "customer-centric" service concept to provide users with more efficient and innovative motion control products and solutions as well as the best services to build a sustainable future for the industry.

Scan the QR code to read on your phone