Promoting the Transformation of DFM Training Achievements——Tracking Report on DFM Training Landing Projects of STEP Schools

- Views:

- Time of issue:2022-12-01 00:00

Promoting the Transformation of DFM Training Achievements——Tracking Report on DFM Training Landing Projects of STEP Schools

- Views:

- Time of issue:2022-12-01 00:00

July 11, 2021 was an unforgettable day. With the push of the start lever, the plaque of the STEP Institute was grandly unveiled, which marked the official launch of the STEP Institute on that day.

In the past one year or so, STEP Institute has adhered to the concept of "talent is strategy" and adhered to the educational purpose of "customer satisfaction, employee pride, and dream achievement". Adhering to the combination of theory and practice, a series of practical and forward-looking high-quality courses have been carried out to continuously empower the company to build an excellent R&D and management talent system.

According to statistics, as of November 2022, STEP Institute has organized multiple training sessions, with a total of more than 300 people participating in the training sessions. The training class for 2022 new graduates, as well as DFM theory and practical training to improve R&D manufacturability. After training, the trainees apply relevant new ideas, new knowledge and new skills to their actual work, and strive to make what they have learned and learn from each other, and the training effect has been initially verified.

Taking DFM training as an example, with the continuous emergence of new projects and new technologies in the company, new product development and introduction often encounter insufficient manufacturability analysis, resulting in poor product and process design, resulting in quality problems and Loss of cost due to change.

In September, after full investigation and understanding by the STEP Institute, a two-day training on "DFM-Reliability Design for Manufacturing" was opened to guide students to consider all aspects of production in the design stage, plan the process route in advance, and improve the product quality. The first-time success rate of the design project prompts the product to be converted to production as soon as possible and introduced to the market in large quantities.

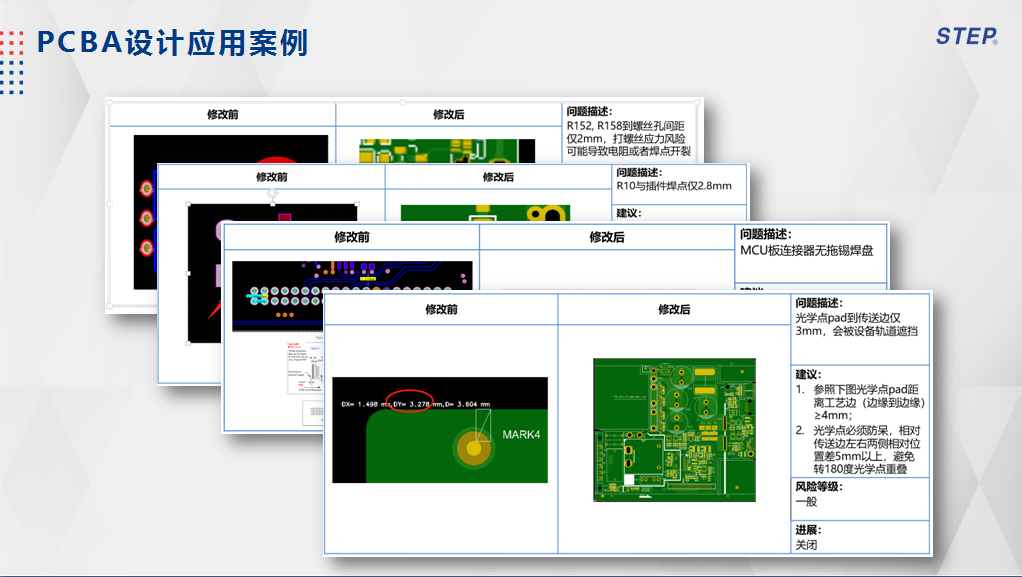

This time, the trainees are all R&D elites from the company's five major business areas, with a total of 90 people. After the training, the R&D engineers had a conceptual framework for the design of the manufacturing process, and put forward many good ideas and viewpoints. The STEP Institute absorbed and summarized this, and selected the PCBA design and structural design as the pilot implementation.

In the subsequent specific implementation, each PCB file and structural design needs to be reviewed before being sent out for processing. In order to prevent mistakes in the review, the method of checklist is specially applied, and the mistakes made before are included in the list and compared one by one. Check to ensure that it is accurate before sending out the board, which will greatly reduce the process problems in the trial production stage. At present, this list has been gradually promoted and applied in the entire research and development system of STEP Group.

This is the STEP school, which plays an important role as a "power source" in the development of STEP. In the future, STEP Institute will continue to shoulder the glorious mission, move forward bravely, build professional and comprehensive training centers and training programs through resource integration, cultivate various talents in the field, and help enterprises transform and achieve strategic goals.

Scan the QR code to read on your phone