■The heavy-duty SCARA has shown its strength and has been locked by customers to send samples

■Intelligent Island Workstation one-stop "breakthrough", play a different kind of exciting

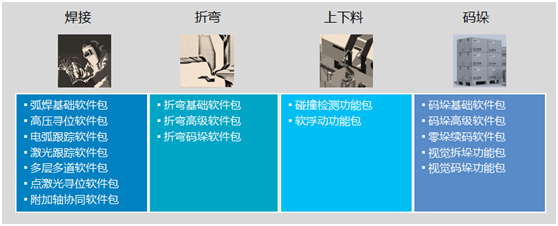

■Software as a Service! SC series rich software realizes function superposition

STEP helps China's high-end intelligent manufacturing!

On October 13, the three-day Seventh International Robot and Intelligent Equipment Expo came to an end in Dongguan. STEP brings robots, motion control products and professional subdivision industry solutions, with the appearance of "scientific and technological innovation, seize the day and night", resonates with the intelligent manufacturing circle at the same frequency, and collides with dazzling sparks.

What are the highlights, worth aftertaste? Let's talk about it.

#01 Parallel with international STEP robots performing a duet of "technology + application"

After ten years of vivid practice, STEP has gone through the gap from prototype research and development to mass production, and adhered to the strategy of "matching imports and surpassing imports". The value exceeds 60%, the factory robot density exceeds 1080 units/10,000 workers, and the palletizing robot 1200 bags/hour...

Technology foundation, application first. STEP always takes the research and solution of on-site process pain points and itching points as the top priority, and can provide customers with rich software packages for welding, bending, loading and unloading, palletizing and other subdivided scene applications, making robot operation easier , easy to use.

STEP depicts a sample of domestic robots that catch up and surpass, and its robot shipments are the first to exceed 20,000 units among domestic robot brands.

In this exhibition, STEP's robot exhibits can be described as a duet of technology + application.

■ The intelligent arc welding system with international advanced two-machine collaborative technology, two SA6/1400 robots communicate through high-speed bus, real-time position interaction, together with single-axis positioner, realize 13-axis coordinated control, which is an anti-corrosion solution for fuel tank welding. Welding deformation provides technical support. Equipped with a high-precision line laser sensor, it perfectly solves the real-time tracking of welds on reflective materials such as galvanized sheets, stainless steel, and aluminum alloys.

■ At the end of August, YR series heavy-duty SCARA new products were officially announced. This exhibition is the first time to officially show the real body. During the exhibition, we also got a definite news - this YR series exhibit has been ordered by a big client, who requested to send samples for testing.

The maximum movement radius of YR series can reach 1200mm, the maximum load is 50kg, the standard cycle time of 10kg load is 0.7s, the standard cycle time of 20kg load is 1s, and the repeat positioning accuracy is ±0.03mm.

Huang Guohui, head of the desktop robot business unit of STEP Zhongweixing, said that the YR series has been optimized through statics and dynamics simulations, as well as optimal parts selection based on multiple constraints such as multi-joint torque constraints, component life constraints, and load inertia ratio constraints. Type and structural parameter design to achieve structural weight reduction, rigidity improvement, and transmission optimization. While ensuring that the strength and rigidity are not weakened, the robot structure is as light as possible. The YR series was born for the lithium battery industry, and at the same time extends to heavy-load, high-beat, high-precision industrial application scenarios such as auto parts and food and beverage.

Also exhibited at the same time: SCARA flexible loading and unloading solutions, robots with flexible feeding and vision systems, one-stop solution to the problem of small varieties and multiple batches of flexible feeding; Axis 5-axis linkage synchronous interpolation high-precision assembly line dynamically follows dispensing, which is very cost-effective.

#02 Smart Island Workstation Becomes "King of Popularity"

Speaking of STEP's intelligent manufacturing business segment, pan-electronics industry integration is an important member of it. It can meet the high degree of customization of customers, and can also provide customers with modularized and functionalized robot integration in the form of standard workstations. STEP's pan-electronic integration business has the advantages of independent research and development technology, engineering design and manufacturing capabilities, delivery and after-sales capabilities.

In this exhibition, the intelligent island workstation, with multiple robots as the main body, demonstrated the perfect automation solution for multi-variety, small-batch and mixed-line production, which well explained STEP's integration capabilities in pan-electronics, and there was an endless stream of visitors. Become the "popular king" of this exhibit.

■ The intelligent island adopts SCARA+STEP six-axis robot, which demonstrates the production services for flexible manufacturing, small batches, multiple varieties, and multi-process mixed lines, which can cover multiple application scenarios such as testing, dispensing, pick-and-place, and locking.

#03 Forum speeches, media focus STEP voice resounds in the audience

On October 12th, STEP also attended two simultaneous forums, and preached the concept of STEP robots and operation control products, which attracted wide attention from the audience.

Zhou Guangxing: From mastering core technologies to leading in market segments

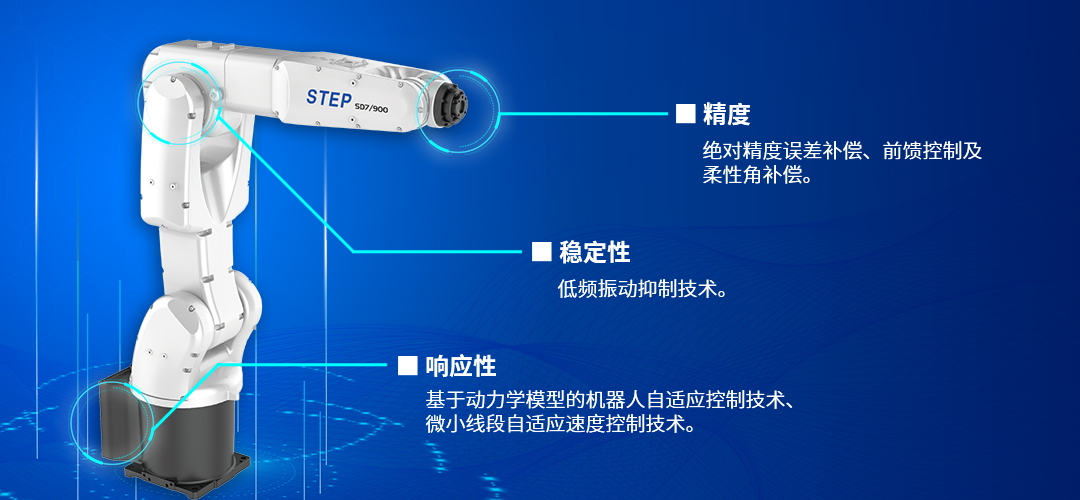

Zhou Guangxing, deputy general manager of STEP and general manager of the Robot Division, believes that based on the mastery of the core technology of the robot motion control system, the performance advantages of STEP robots lead the industry in an all-round way.

The technical advantages of STEP robots are also reflected in software development. Zhou Guangxing said: "Our goal is very clear, which is to provide users with powerful and easy-to-use application software packages. This requires us to be proficient in craftsmanship, that is, to deeply understand the craftsmanship and enable robot applications; easy to operate: for industrial workers The practical level, easy operation, makes the robot easier to use.”

Zhou Guangxing also shared the cases of Haier's first domestic robot intelligent production line undertaken by STEP, China Power Construction's tower foot welding workstation, CANNY elevator car frame door panel welding and bending intelligent production line, steel structure large-scale component welding intelligent production line, etc. .

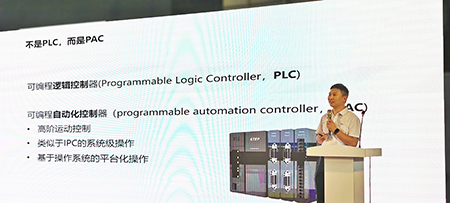

Cao Haixiao: SC intelligent control platform helps China's intelligent manufacturing

The SC series has attracted much attention from the industry since it was launched last year. At present, there are two products, SC20 and SC30. STEP defines it as a programmable automation controller (programmable automation controller, PAC). For this reason, Cao Haixiao, head of the STEP motion control product BU, pointed out that the PAC is more like a PC, which encapsulates high-level motion control, system-level operations similar to IPC, and platform-based operations based on operating systems.

Compared with PLC, PAC platform-based products can provide robot control, CNC numerical control, PLC logic control, loT edge computing and other functions on the same platform, and do not require special hardware or firmware upgrades, only need to switch between different software configurations, that is, Realize robot and CNC control such as multiple coordinate systems.

△The SC30 multi-axis synchronous control system on display

Cao Haixiao said that STEP put forward the slogan of "software as a service", hoping to abstract hardware functions into software, and realize the superposition of future functions through the enrichment of software. The powerful performance of the SC series not only comes from the embedded high-speed FPGA and the innovative patented synchronization algorithm, but also thanks to the patented multi-machine collaboration technology.

He further explained that unlike the practice of general manufacturers, one SC series product can simultaneously control multiple robots or CNC machine tools and robots to realize mixed programming of multiple machines. This only requires software switching, and one interface can Finish.

Cao Haixiao believes that the technological achievements of the SC series can contribute to the realization of China's smart manufacturing technology for cornering overtaking, and have potential markets in various industries such as robotics, textiles, lithium batteries, machine tools, and even aviation manufacturing.

During the exhibition, STEP also received visits from a number of media, among which the robot made an online live report on the STEP booth, and through their lens and text, they called together for China's high-end intelligent manufacturing.

Wisdom makes beauty, the road is long and difficult

Step by Step, Dreams Come True

See you at China Industry Fair (Shanghai) on December 1!