Precise tin delivery, soldering follow the shape | Zhongweixing released the HX8849V1 soldering control system

- Views:

- Time of issue:2020-11-17 00:00

Precise tin delivery, soldering follow the shape | Zhongweixing released the HX8849V1 soldering control system

- Views:

- Time of issue:2020-11-17 00:00

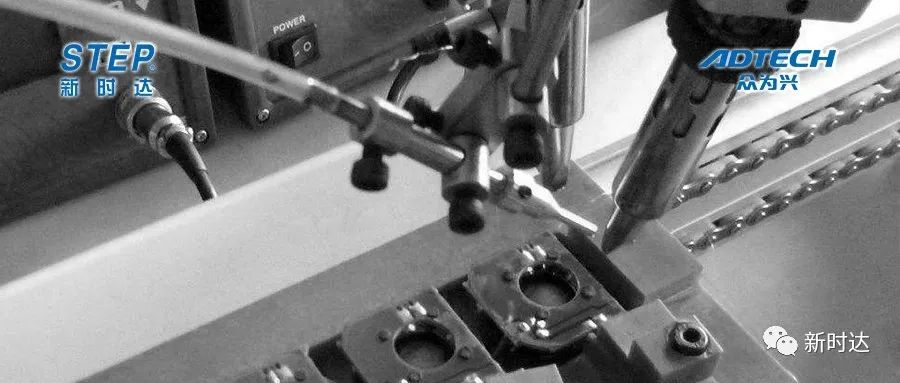

HX8849V1 (four-axis) soldering control system

Precise delivery of tin, solder moves with the "shape"

The multi-axis manipulator cooperates with HX8849 for linkage, accurate tin delivery, stable speed, ideal welding effect, and remarkable work efficiency. It is widely used in 3C, automotive electronics, solar photovoltaic, LED and other industries.

1. Equipped with A9 dual-core processor, and adopt the advanced motion control algorithm of Zhongweixing

◆ HX8849V1 controller has high operating efficiency and stability, which ensures precise and controllable solder delivery, and the molten tin can quickly reach the solder joint position, improving the operation efficiency.

◆ S-shaped curve, T-shaped acceleration and deceleration mode, and acceleration and deceleration acceleration can be set independently; the speed refresh rate of 5K makes the mechanical response performance better and the noise smaller.

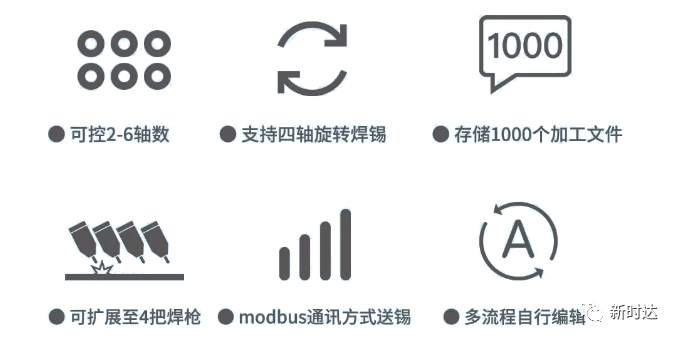

2. Maximum support for 4 welding torches soldering at the same time

Supports four-axis interpolation soldering, three-axis double-station automatic alternate operation, can use modbus communication to control the tin feeding axis for tin feeding, and can be expanded to 4 welding torches for simultaneous soldering. Up to 18 outputs, up to 34 inputs.

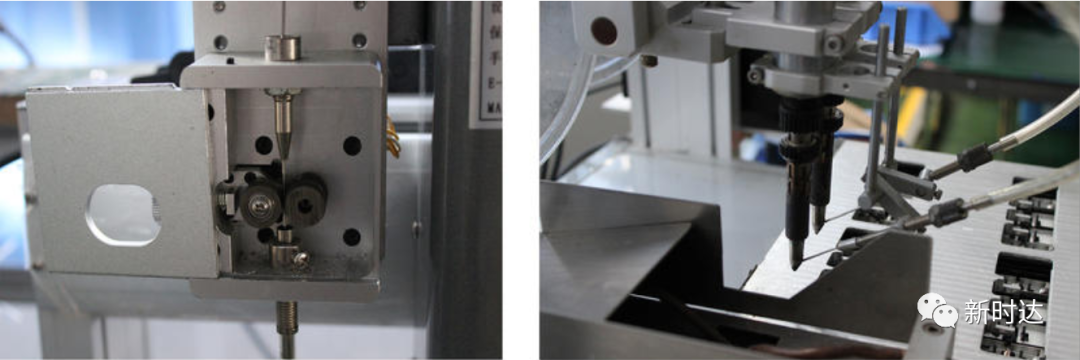

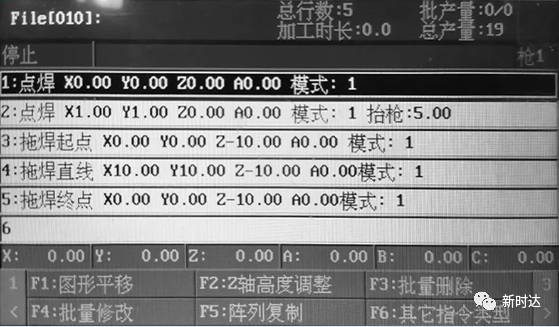

3. Rich processing instructions, spot welding, drag welding at will

It supports rich processing instructions such as spot welding, linear drag welding, arc drag welding, full circle drag welding, and file calling.

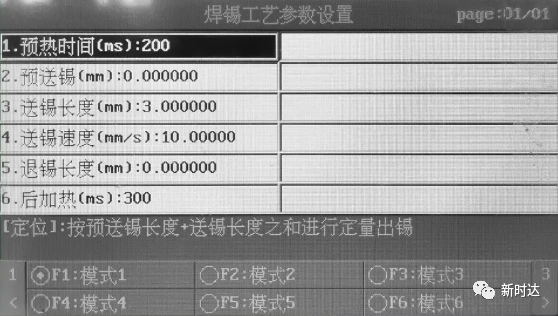

Users can change the process parameters according to different welding torch models, power and pad requirements.

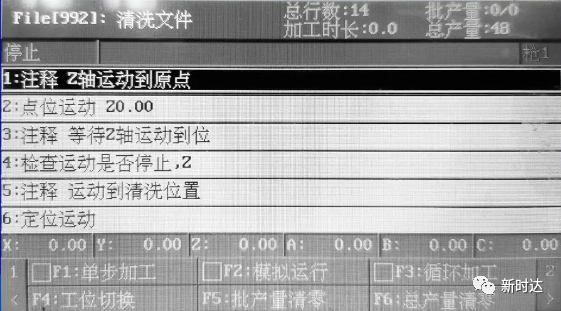

4. Custom reset, cleaning and other action settings

Support users to edit reset, stop, standby position, cleaning and other action commands by themselves to meet more personalized customer needs.

5. The controller has multiple sets of memory for soldering conditions, which can be set according to different types of solder joints

Large storage capacity, can store 1,000 processing files, each file can store 10,000 processing instructions, and support up to 30 sets of process parameters.

Scan the QR code to read on your phone