DME China Machine Tool Show | STEP's new products in operation and control are launched

- Views:

- Time of issue:2020-11-17 00:00

DME China Machine Tool Show | STEP's new products in operation and control are launched

- Views:

- Time of issue:2020-11-17 00:00

From November 11th to 14th, 2020, DME China Dongguan Machinery Exhibition was grandly opened in Houjie·Guangdong Modern International Exhibition Center, Dongguan. The exhibition comprehensively displays new technologies in the field of machining, and discusses and exchanges industry trends.

STEP , as a leading motion control expert, exhibited Ω6 AC servo system, SC30 series PCL controller, CNC9810 six-axis CNC milling machine control system, Ωm-N1 multi-axis servo system, Ωs-AN1 AC servo system at this exhibition , iK2 series servo, integrated integrated servo and other latest operation and control products.

1. New product notice

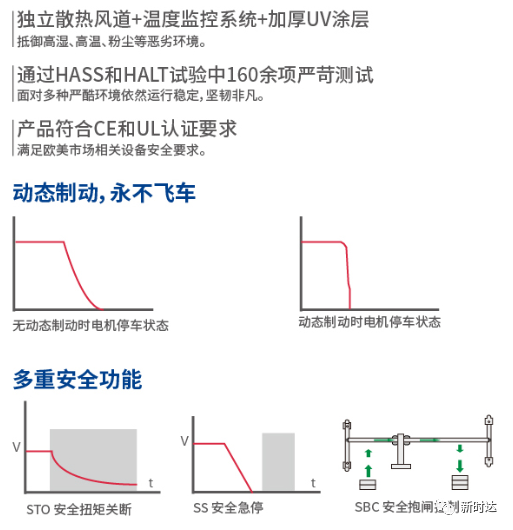

1. The Ω6 AC servo system

is powerful and ready to use out of the box

I have everything you want

Safe and reliable multiple protection

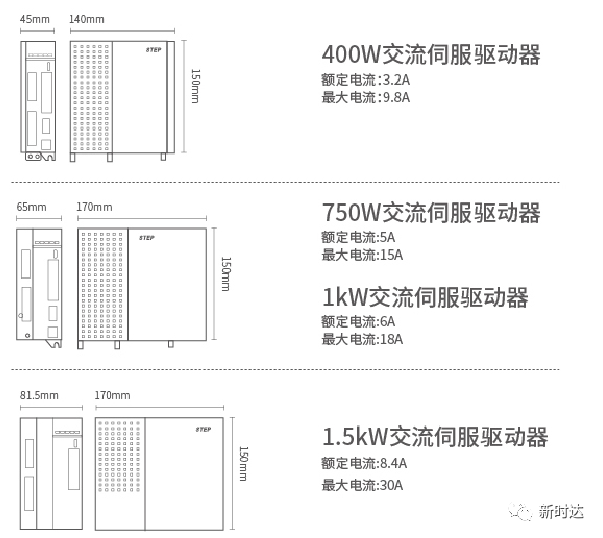

Different power meets different challenges

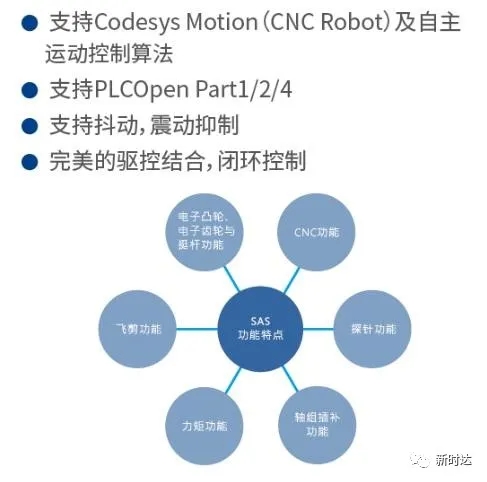

2. SC30 series PCL controller

Operation and control experts are trustworthy

Easy to use one-click generation

2. Professional control system

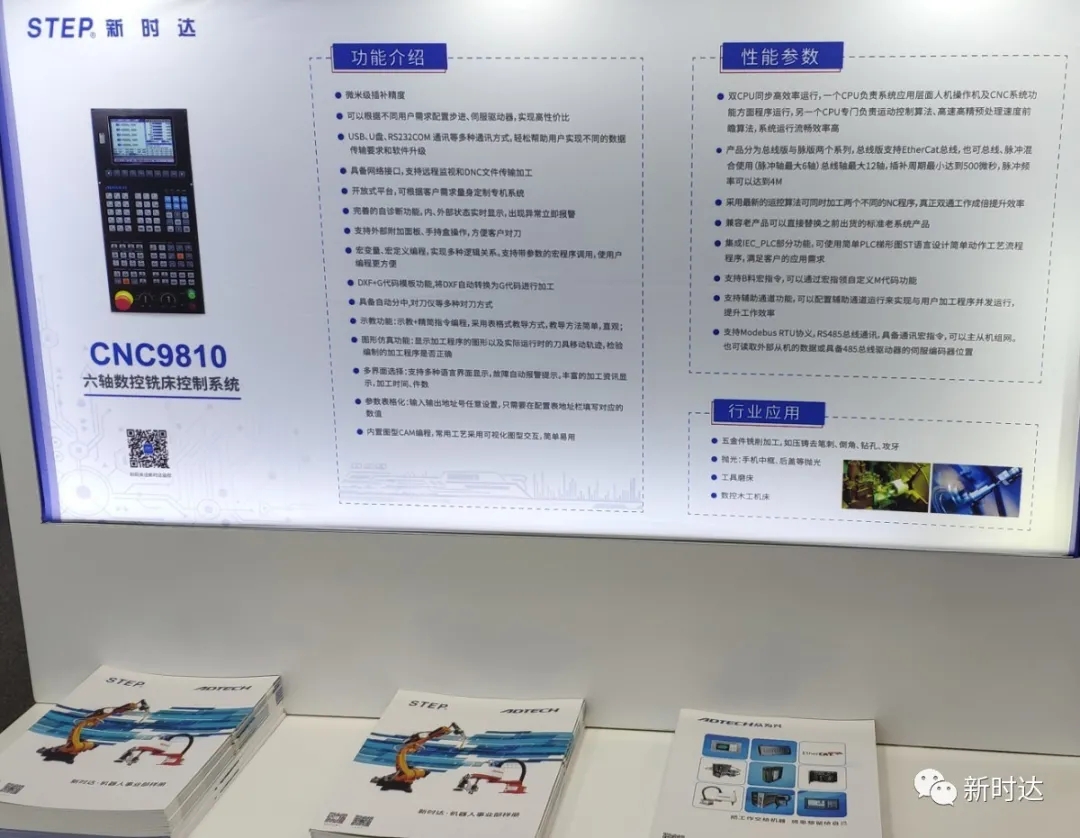

1. CNC9810 six-axis CNC milling machine control system

◆Micro-level interpolation accuracy.

◆Configure stepping and servo drives according to different user needs to achieve high cost performance.

◆Various communication methods such as USB, U disk, RS232COM communication, etc., easily help users realize different data transmission requirements and software upgrades.

◆Built-in graphic CAM programming, common processes adopt visual graphic interaction, easy to use, etc.

3. Servo drive

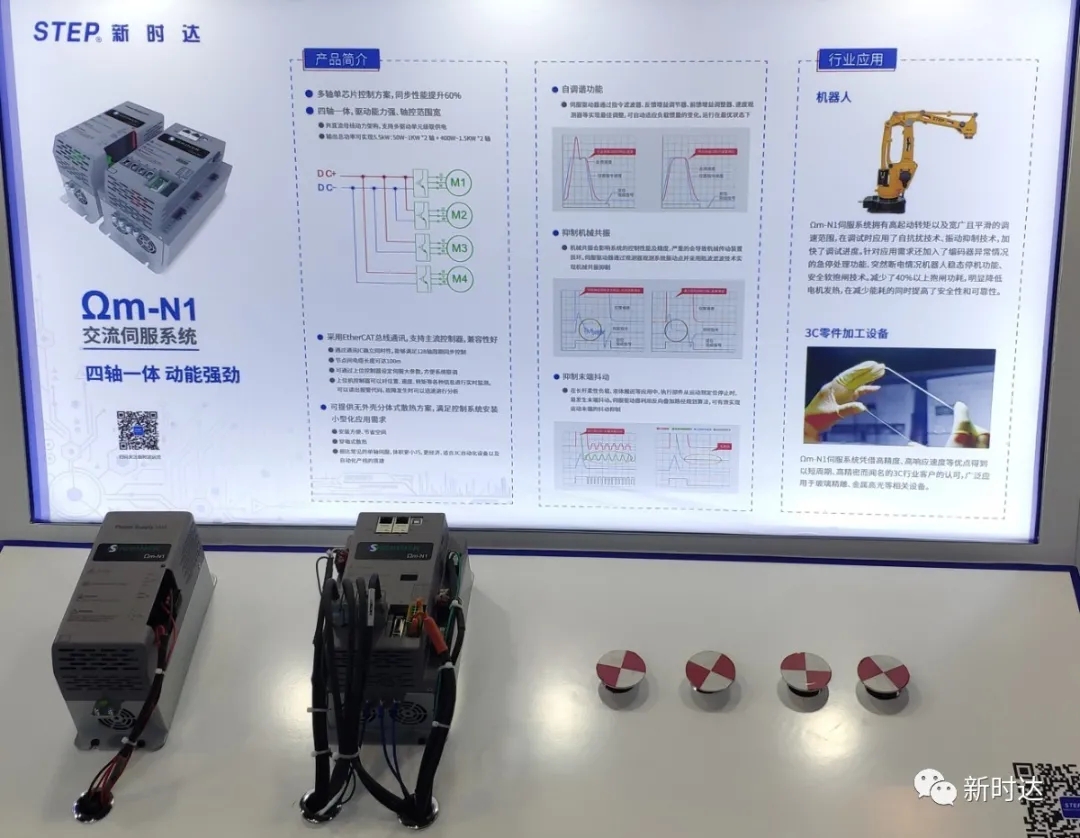

1.Ωm-N1 multi-axis servo system

◆Four-axis integrated, strong drive capability, wide range of axis control.

◆Common DC bus power structure, supporting cascade power supply of multiple drive units.

◆Use EtherCAT bus communication, support the mainstream controllers in the industry, and have good compatibility.

◆Multi-axis single-chip control scheme, the synchronization performance is improved by 60%.

◆Separate heat dissipation scheme without casing can be provided to meet the application requirements of miniaturization of control system installation.

2.Ωs-AN1 AC servo system

◆Support EtherCAT, CANopen bus communication.

◆The current execution cycle is less than 1μs, which effectively improves the servo response speed.

◆Current loop synchronization algorithm, multi-axis synchronization performance is superior.

◆Load friction compensation, more precise position control.

3. iK2 series servo

◆Standard MechatrolinkII and MechatrolinkIII buses are perfectly adapted to CNC systems such as Baoyuan, Xindai, and Edraw.

◆Kalman observer algorithm makes the servo response faster.

◆Load disturbance compensation algorithm makes the processing more stable. Debugging software supports functions such as analysis of mechanical characteristics, parameter setting, monitoring, etc., and the operation is intuitive and simple.

◆Quadrant protrusion suppression algorithm makes the processing finer.

4. Integrated integrated servo

◆Using 32768 high-resolution encoder, the position control is more precise.

◆Within 3000rpm, the rated torque output can be guaranteed at any speed.

◆The speed is more stable and the running noise is low.

◆With pulse control, CAN bus control, MOBUS bus control functions.

◆With pulse control, CAN bus control, MOBUS bus control functions.

Scan the QR code to read on your phone