All for Prosperity丨Lithium battery industry automation solutions

- Views:

- Time of issue:2020-10-30 00:00

All for Prosperity丨Lithium battery industry automation solutions

- Views:

- Time of issue:2020-10-30 00:00

The《New Energy Automobile Industry Development Plan》 was released, and the power battery industry has received great benefits again, and battery companies have stepped up their layout. However, the production of lithium batteries is complex and requires about 10 processes from raw materials to finished batteries. Each process will minimize human intervention to ensure the safety and consistency of the final finished battery cells. To improve the level of automated production, it is necessary to improve on the agenda.

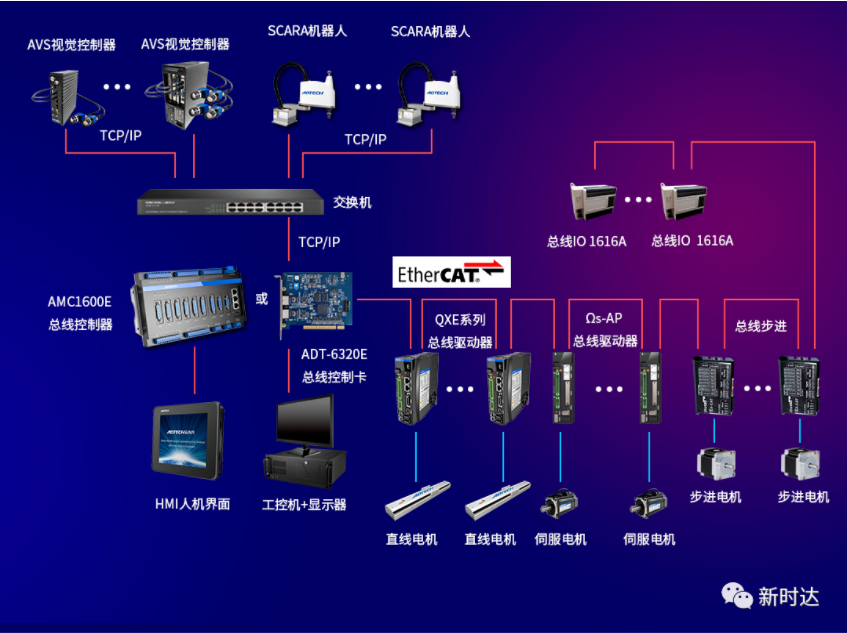

For the whole process production line of the lithium battery industry, STEP Group provides a complete set of automation solutions. Based on Zhongweixing bus controller/card, servo, and HMI, it can realize motion control solutions for equipment and line bodies in various process segments from electrode production, cell assembly to post-processing, ensuring production and processing accuracy and stability.

The SCARA robot, combined with AVS vision, can quickly connect multiple processes such as lamination, tab pre-welding, inspection, welding, gluing, coating, hot-melting, and shelling, and complete flexible operations that focus on upper and lower materials.

1.

The process in which the spot welding lug and the base are fused together through the welding head.

ADT-6320E control card applied to automatic double-sided spot welding machine

2. The lamination

assembles the positive and negative electrodes and the diaphragm together, and after the glue is pasted, the pole core is formed.

ADT-6320E control card is applied to stacking machine

3. Sorting of soft-packed batteries is

performed by electrically testing the arrayed battery packs, thereby sorting the batteries.

ADT-6320E control card is applied to soft pack battery sorting machine

4. SCARA loading and unloading

AR5215 is loading and unloading on the lithium battery stacker.

◆Lamination speed: 60ppm

◆Lamination precision: ± 0.025mm

◆Replacing Japanese imported brands

◆Cooperate with vision for material positioning and grabbing

System advantages

◆EtherCAT bus control, fast servo response, strong anti-interference ability, self-tuning to simplify debugging.

◆Innovative direct drive technology: get rid of the reducer and screw rod, and greatly improve the accuracy of the equipment.

◆Efficient and stable motion control products ensure efficient and stable operation of equipment and effectively control speed fluctuations.

◆SCARA multi-model selection, more than 20 types of lithium battery technology application experience, fast pace and high precision, with application functions such as command programming, visual calibration, visual capture, PLC communication, IO input and output, fast palletizing and waiting.

◆Personalized solution: help plan the overall machine design and break through the bottleneck of equipment speed.

Scan the QR code to read on your phone