Supported by Zhongweixing bus solution, glass polishing is more efficient and more textured

- Views:

- Time of issue:2020-05-29 00:00

Supported by Zhongweixing bus solution, glass polishing is more efficient and more textured

- Views:

- Time of issue:2020-05-29 00:00

【STEP Group | Zhongweixing】 2.5D glass has been widely used in mobile phone covers, car display screens, smart watch display screens and other products. In its processing, it can generally be upright around its surroundings by a CNC sweeping machine. Sweep the surface to improve transparency and texture.

Zhongweixing pays close attention to various technical difficulties in the mobile phone industry chain. The bus control solution for mobile phone glass sweeping machines launched for the polishing equipment industry has won the favor of many customers for its cost-effective features.

For the multi-axis application of scanning machines, Zhongweixing AMC1600E bus-type motion control and QXE bus servo system can not only improve the positioning accuracy and stability of the whole machine, but also give full play to the advantages of efficiency and flexibility.

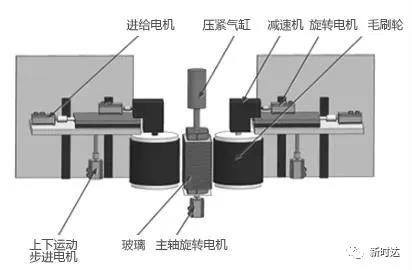

The overall structure of the seven-axis 2.5D sweeping machine on the market can be divided into two parts, one part is to press the workpiece through the compression cylinder, and the servo drives the workpiece to rotate; the other part is the left and right polishing brush wheels, which are driven by the servo motor according to the The program performs profiling feed motion along the edge of the workpiece, and can also do up and down and rotation motions at the same time.

The grinding trajectory is enveloped by the movement of the brush and the workpiece rotation axis, and the contour curve is compensated and adjusted according to the implementation of the torque.

Electrical configuration diagram

The scheme adopts EtherCAT system bus type motion controller AMC1600E, QXE bus servo driver.

Program features

1. Segmented speed is adjustable

Divide the processed object into several segments, each segment’s speed is adjustable, by controlling the spindle speed, adjust the linear speed of the contact part between the workpiece and the brush, so as to achieve constant linear speed grinding, which greatly improves the grinding quality , reducing the difficulty of glass bending and surface grinding.

2. Real-time torque compensation

Using the electronic cam function of AMC1600E, the brush and the intermediate workpiece rotation axis envelop the grinding trajectory. Through real-time torque compensation, the electronic cam profile curve is adjusted to ensure uniform sweep removal and high contour consistency.

3. Support DXF file map

In glass scanning applications, there are often high requirements for processing contour curves. Therefore, many machining trajectory curves are usually designed by CAD software, and the DXF file is the standard format. This application fully supports DXF file maps.

Implementation Effect

The accuracy of the whole machine can reach ±0.01mm. The control system adopts the AMC1600E electronic cam plus torque compensation method, which only needs one controller to control, which not only meets the requirements of high-precision processing, but also realizes the controllable hardware cost. Compared with the traditional CNC control or PLC+vision control scheme, it has obvious advantages.

Zhongweixing's sweeping machine control scheme is very mature and has been widely used in the polishing industry.

Scan the QR code to read on your phone