Singlina Servo Product Launch Conference and Operation and Control Enterprise Exchange Conference was held grandly

- Views:

- Time of issue:2019-09-09 00:00

Singlina Servo Product Launch Conference and Operation and Control Enterprise Exchange Conference was held grandly

- Views:

- Time of issue:2019-09-09 00:00

In recent years, with the continuous strengthening of the product technology strength of China's local transportation and control enterprises, the trend of cooperation between domestic and foreign enterprises is obvious. With the trend of emerging technologies such as 5G, provide high-quality, high-performance, customized motion control products and solutions for China's manufacturing industry. The complementary cooperation between Singlina Germany and STEP Group was born from this.

On September 6th, the "Singriner Servo Product Launch Conference and Transportation Control Enterprise Exchange Conference" jointly sponsored by China Transmission Network, Shanghai Sigliner STEP Motor Co., Ltd., and ITES Shenzhen Industrial Exhibition was held in Bao'an, Shenzhen. More than 100 people attended Persons in charge, engineers and technical leaders from 3C electronic equipment, laser, numerical control, robot, lithium battery and motion control enterprises attended the meeting to talk about the development of the industrial control automation industry in the era of 5G transformation, and witnessed Singliner Ω series servo products Landed in the Chinese market.

In the future, let customers forget the existence of servo

At the beginning of the event, Tan Weijia, Deputy Secretary-General of Shenzhen Robotics Association, delivered a speech.

Liu Weidong, Deputy Secretary-General of China Motion Control Industry Alliance

Deputy Secretary-General Liu Weidong analyzed the industrial market situation in 2019. In 2018, the growth of the automation market slowed down significantly, and there will still be considerable downward pressure in 2019. It is expected that starting in 2019, with the warming of the macro economy, the automation market will gradually return to the "new normal" growth state. Benefiting from the post-supply-side reform dividend, the project-based market developed rapidly in 2018/2019. Investment in smart manufacturing continues to grow at a high rate, and the transformation of projects into government investment and independent investment by enterprises keeps pace. However, the overall implementation is more difficult than expected, and there is broad room for improvement in the future. Key industries are gestating new opportunities in intelligent manufacturing, the trend of conversion of old and new kinetic energy remains unchanged, and the trend of industrial upgrading remains unchanged. At the same time, domestic brands are becoming more and more mature, and the trend of localization is obvious, and industry colleagues need to continue to work hard.

Shao Yongfeng, General Manager of Shenzhen Chengzi Automation Co., Ltd.

General Manager Shao Yongfeng believes that under the influence of factors such as difficulty in recruiting workers, rapid product update iterations, and a new machine replacement cycle in the 5G era, the 3C industry has an urgent need for automation upgrades. In this regard, automation equipment manufacturers in the 3C industry should make equipment intelligent, flexible, modular and other industries fail to do well, 5G, chip testing and other industries have not done well, and industries such as high-end talents, core technologies, and opportunity barriers cannot do well. Do a good job of many problems, be an equipment manufacturer with differentiated competitive advantages, manufacture equipment that meets customer needs or what customers want, and provide users with faster return on investment and equipment that meets the standards of future smart factories.

Cheng Jun, Vice President of Technology, Foshan Hongshi Laser Technology Co., Ltd.

Vice President Cheng Jun analyzed the development status and future prospects of the laser industry. As the laser power continues to increase and the speed and acceleration of the cutting machine are getting higher and higher, the transmission parts are an important guarantee for the accuracy and life of the cutting machine tool, and their performance is becoming more and more important: considering the accuracy level, dynamic and static load, and service life of the linear guide rail, the laser The cutting machine is recommended to use linear guides above H level; the motor needs to meet the requirements of high stability, high precision, and fast response, and try to choose a low-inertia motor; Stability, actual backlash, input and output torque and other performances.

Dr. Ding Xinzhong, Central Research Institute of STEP (Group)

Dr. Ding Xinzhong pointed out that servo products are developing in the direction of free debugging, high performance, high power density, safety, and intelligent interconnection. In short, it means "let customers forget the existence of servo". The new "All-in-One" integrated motor and drive system and the "multi-axis drive and control integrated" topology structure are aimed at the different needs of more or less axes, high and small power, and the degree of dispersion and concentration of physical space. It subverts the traditional complex operation and control structure mode, only one power line is needed, which greatly improves the operation efficiency of the whole machine; and integrates intelligent fault diagnosis function, fault-tolerant control, health management and intrinsic safety in the servo drive system, It greatly reduces the risk of failure and improves the safety of operation; at the same time, it achieves advanced performance such as debugging-free, parameter self-tuning, high-precision control, and friction compensation. In addition, the servo system design based on wide bandgap devices also opens the silent mode of servo products.

New products come out, interpreting the ultimate control experience

▲▲▲

At the event site, Siegliner's Ω series servo products were unveiled intensively, demonstrating the core technology of German drive control.

Wang Gangzhi, Chairman of Hangzhou Zhishan Intelligent Control Technology Co., Ltd.

Chairman Wang Gangzhi said that Singlina has been focusing on the technology development of drive and control products, while STEP is a well-known brand of intelligent control drives in China and a leading enterprise in intelligent manufacturing comprehensive solutions. Sigliner's R&D team and the Central Research Institute of STEP Group jointly developed the Ω series servo products, and Zhishan Zhikong and its subsidiary Baijiang Intelligent will be responsible for product promotion and services, bringing users excellent drive and control product experience and The ultimate solution.

Jiang Ronghui, product director of Singliner, explained the Ω series servo products to the participants

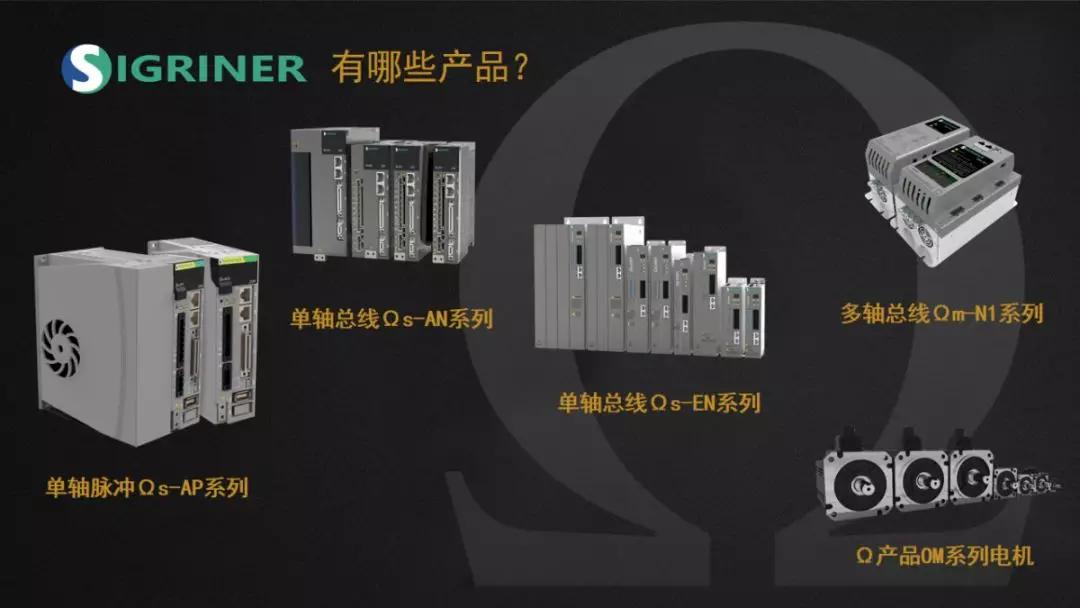

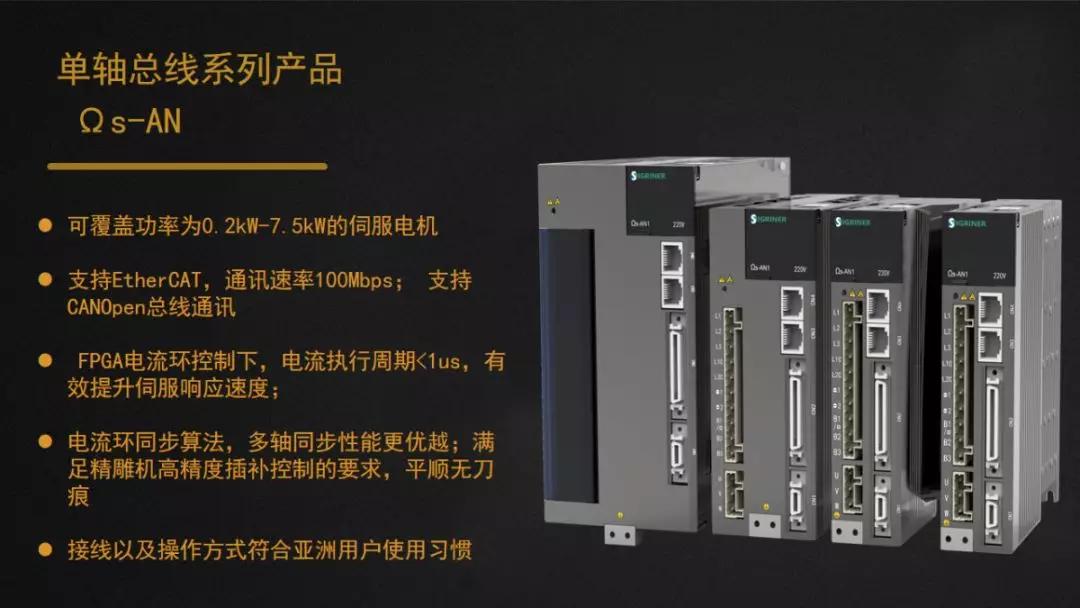

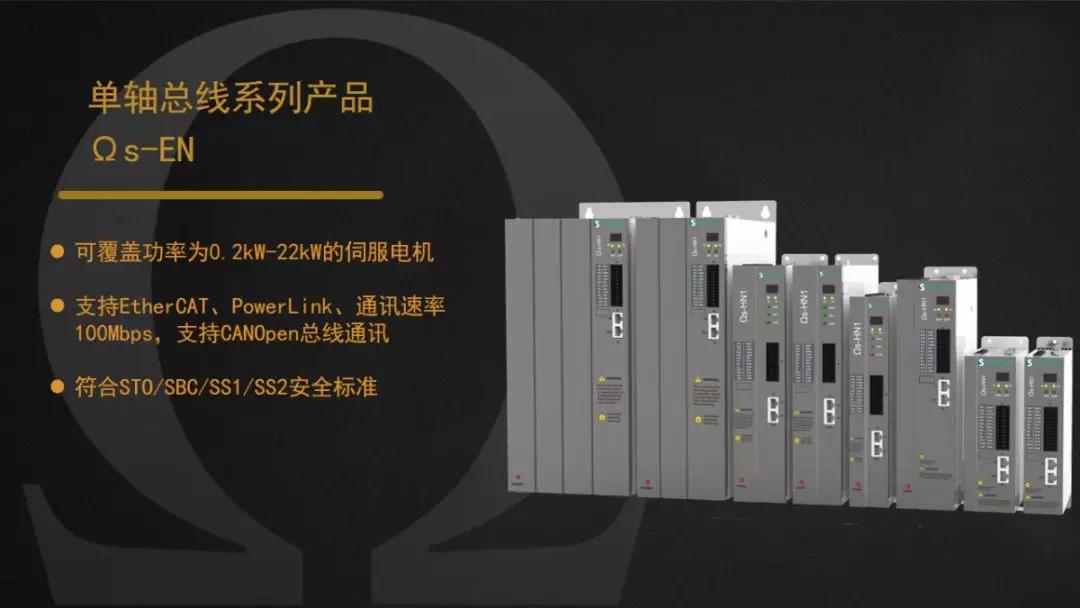

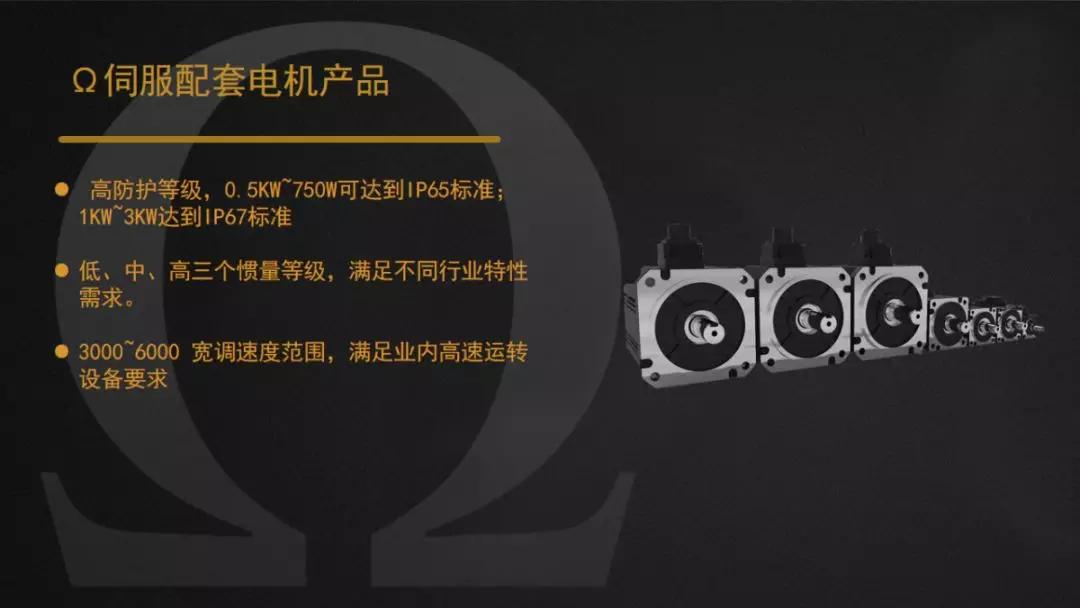

Ω series servo products have the advantages of cost saving, fast response, accurate positioning, and stable operation , covering Ωm-N1 series multi-axis servo drives, single-axis Ωs-AN1 series servo drives, single-axis Ωs-EN1 series servo drives, single-axis Ωs -AP1 series servo drives, Ω products OM series motors and other products.

The product has excellent compatibility and can support multiple brands of EtherCAT device controllers and various encoder interface motors, such as Tamagawa, Nikon, and Panasonic encoders. In terms of performance, the Ω series servo products also have the characteristics of integrated inertia self-learning, parameter self-tuning, motor cogging torque compensation, dynamic friction compensation, self-interference rejection, suppression of end vibration and mechanical resonance, and safety protection under abnormal conditions. The control is precise, Fast response and stable operation; mainly used in robot, lithium battery, CNC, LED, glass panel processing, photovoltaic and other industries.

As a major industrial manufacturing country, China's industrial automation market is vast and has always been an important place for competition. As the potential of the Chinese market is developed, cooperation and innovation between domestic and foreign enterprises will gradually become the norm.

The launch of the Ω series servo products includes more than 40 years of Singliner's German technical background and excellent manufacturing process, relying on STEP's rich experience in the industrial automation market for many years and a sound service network, and accurately controls the application needs of the Chinese market. Integrating into the manufacturing concept of China's smart factory, it has achieved the perfect integration of German quality and Chinese speed. It is a successful demonstration of strong cooperation between domestic and foreign high-quality transportation and control companies.

Looking forward to the future, Sigliner Ω series servo products serve Chinese manufacturing enterprises accurately and efficiently with excellent product quality, and contribute a solid technical foundation for the construction of a new era of intelligent manufacturing in China.

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Highlights

Scan the QR code to read on your phone