Investigation notes of Luo Junjie and his party from the Ministry of Industry and Information Technology

- Views:

- Time of issue:2017-07-12 00:00

Investigation notes of Luo Junjie and his party from the Ministry of Industry and Information Technology

- Views:

- Time of issue:2017-07-12 00:00

On July 6, Luo Junjie, deputy director of the Equipment Industry Department of the Ministry of Industry and Information Technology, and the head of the Machinery Department came to Shanghai to investigate related companies in the robot and key parts industry. Huang Ou, deputy director of the Shanghai Economic and Information Commission, and others participated in the investigation. Deputy Director Luo Junjie and his team successively investigated Shanghai Lectra Precision Machinery Co., Ltd., Shanghai Electrical Appliance Science Research Institute (Group) Co., Ltd., and Shanghai STEP Robotics Co., Ltd. to carefully understand the development status and problems faced by Shanghai's robot and key parts industry. Listen to the appeals and suggestions of enterprises, and discuss the application and development trend of the industrial market of robots and key components.

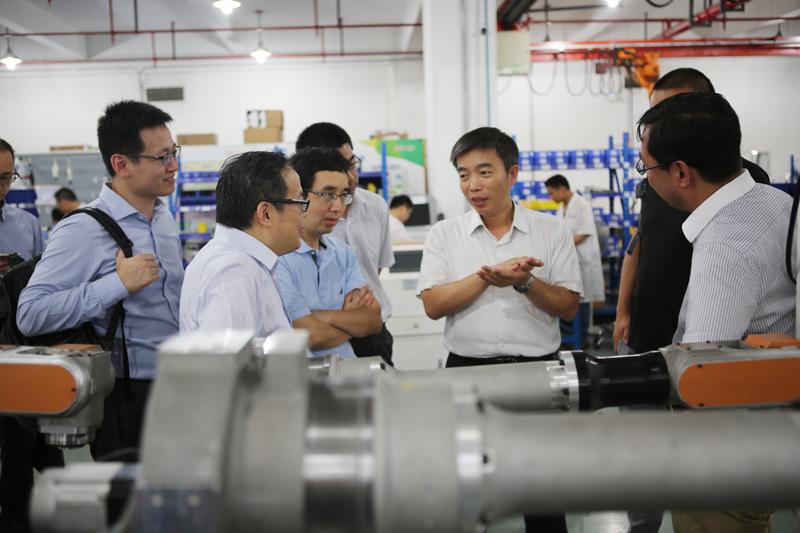

The research team visited the STEP robot workshop

The research team visited the STEP robot workshop

In STEP, senior executives including Vice Chairman Yuan Zhongmin and Robot R&D Director Dr. Zhang Minliang participated in the survey. Vice President Li Guofan focused on the layout and development of STEP's intelligent manufacturing sector. Dr. Zhang Minliang introduced the core technology and new development trends of STEP robots.

Smarter and easier to use, the development direction of STEP robots

Dr. Zhang Minliang: The market feedback in recent years shows that unlike automobile factories who have rich experience in using robots, a large number of small and medium-sized customers who have needs for robots are relatively new to industrial robots. strangeness. For example, a welding workstation uses one or two robots to teach and program the robots according to the existing methods; the result may be that several welders are replaced on site, in exchange for robot operators who need higher salaries. In this case, it is problematic for the comprehensive use cost of the enterprise. Therefore, we believe that smarter and easier-to-use robots will be welcomed by small and medium-sized customers.

Robot assembly robot, more intelligent

Dr. Zhang Minliang: At the International Robot Exhibition held at the National Convention and Exhibition Center, we used a 6kg small robot to assemble a 210kg robot wrist.

robot assembly robot

Using a six-dimensional force sensor to design an impedance control algorithm to make the end of the robot soft, using this method can control the change of contact force and avoid damage to objects caused by hard contact. At the same time, the design hole search algorithm or the grinding trajectory adaptive algorithm can effectively compensate the teaching error, and the assembly and grinding process is more intelligent. During the assembly process, relative changes in the position of the hole are allowed, and the robot can automatically find the installation position, respond to environmental changes or unknown errors in the workpiece manufacturing process in a timely manner, and ensure the safety of the robot and the assembled workpiece.

Precise control of the contact force between the robot and the workpiece reduces the requirements for the consistency of the hole position, reduces the difficulty of teaching, and ensures that the workpiece will not be deformed and damaged during the assembly process. Robot automatic assembly, which is a very good way to replace human labor. It is believed that this technology will be widely used in the fields of assembly, grinding, decoding and stamping.

Dr.

Zhang Minliang: The dragging and teaching robot exhibited at the same time is very easy to use. A six-dimensional force sensor is installed at the end of the robot to realize the drag and teach function of the robot, and realize the programming requirements of the robot simply and quickly. This is also a concrete manifestation of "ease of use".

Robot dragging and teaching∣ Drive and control integrated control system

Using the latest drive-control integrated control system, the speed response ability is super strong, and it has powerful functions such as load torque observation, offline observation and identification, high and low frequency oscillation suppression, and active disturbance rejection control; supports EtherCAT bus protocol, and supports single-node multi-axis synchronization Drive; full anti-collision function, which can realize quick stop after collision.

The control system can be equipped with STEPSA1400, SD500, SD700 robots, and will be widely used in 3C assembly, workpiece welding, decoding, loading and unloading of machine tools and other fields.

Dr. Zhang Minliang also introduced the exploration and research of STEP robots in vision and Internet of Things. In short, we need to subvert the traditional way of using robots, so that small and medium-sized customers can afford and use robots, and robots are smarter and easier to use. This is what our domestic robots should do.

During the survey, Deputy Director Luo had an in-depth understanding of the core technology of STEP robots, the layout of the intelligent manufacturing industry chain, and domestic and foreign market expansion. make due contributions.

Research team and STEP participants

Research team and STEP participants

Scan the QR code to read on your phone