Applications:Cell phone industry

Keywords:SCARA Robot

Related products:

In automated production lines, vision systems are often used for automatic positioning of workpieces during robot loading and unloading. By accurately identifying the position of workpieces, unnecessary losses caused by mechanical positioning, alignment devices and workpiece collision, extrusion, etc. are avoided. This simplifies the process complexity of mechanical positioning in production lines, effectively shortens positioning time, and improves robot loading and unloading efficiency and flexibility.In automated production lines, vision systems are often used for automatic positioning of workpieces during robot loading and unloading. By accurately identifying the position of workpieces, unnecessary losses caused by mechanical positioning, alignment devices and workpiece collision, extrusion, etc. are avoided. This simplifies the process complexity of mechanical positioning in production lines, effectively shortens positioning time, and improves robot loading and unloading efficiency and flexibility.

We can provide a full set of loading and unloading automation solutions for cell phone glass processing. Among them, in the screen printing process section, SCARA with integrated AVS vision system can quickly and accurately grasp and place multiple workpieces and large field of view for cell phone glass in one shot, thus improving production efficiency.We can provide a full set of loading and unloading automation solutions for cell phone glass processing. Among them, in the screen printing process section, SCARA with integrated AVS vision system can quickly and accurately grasp and place multiple workpieces and large field of view for cell phone glass in one shot, thus improving production efficiency.

Project OverviewProject Overview

The cell phone glass cover plays a protective and beautiful role for the cell phone touch screen, screen printing is a process to process it, that is, the pattern or LOGO and other information printed on it, and then also need to dry the ink through the oven.The cell phone glass cover plays a protective and beautiful role for the cell phone touch screen, screen printing is a process to process it, that is, the pattern or LOGO and other information printed on it, and then also need to dry the ink through the oven.

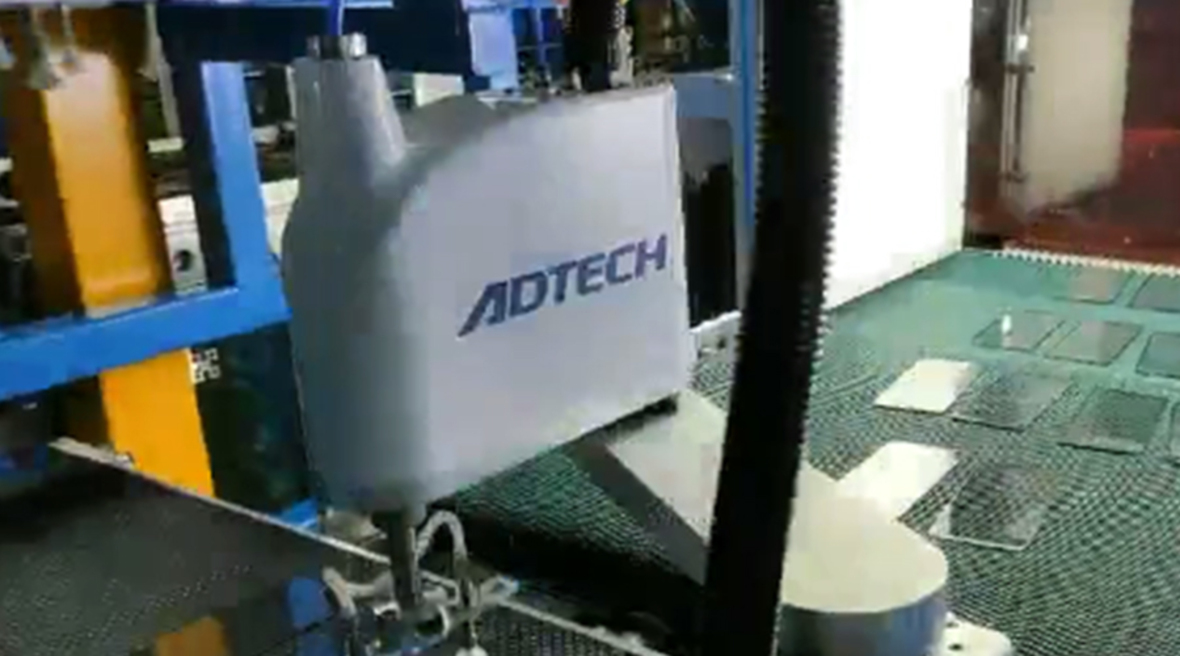

In this project, the glass from the oven is transported backwards by conveyor belt according to a row of 5 workpieces (about 15.5 inches), during which the workpieces are positioned by the AVS vision system of Zong ADTECH, camera shooting, and when the workpieces flow to the gripping range, the robot immediately picks up the workpieces one by one, and thereafter waits for the PLC's permission to release signal, and finally puts the workpieces to the fixed position.In this project, the glass from the oven is transported backwards by conveyor belt according to a row of 5 workpieces (about 15.5 inches), during which the workpieces are positioned by the AVS vision system of Zong ADTECH, camera shooting, and when the workpieces flow to the gripping range, the robot immediately picks up the workpieces one by one, and thereafter waits for the PLC's permission to release signal, and finally puts the workpieces to the fixed position.

△Mobile phone glass workpiece△ Mobile phone glass workpiece

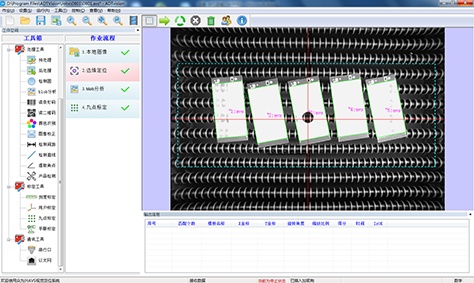

△HMI program interfaceHMI program interface

ConfigurationConfiguration

ADTECH AR5215 SCARA + ADTECH AVS2300 Vision Positioning System

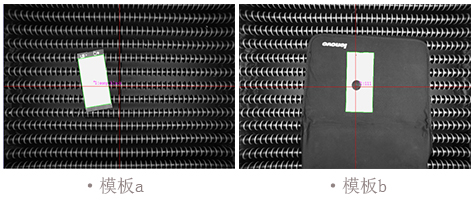

For the cell phone glass after screen printing, the vision system uses blob analysis.

In machine vision, a blob is a connected area in an image with similar color, texture and other features. Simply put, blob analysis is the geometric analysis of a connected area to get some important geometric features.

For this project, the conventional localization method will result in missed shots, false shots and so on, while adding blob analysis can improve visual localization stability by extracting and filtering multiple key areas of the glass!

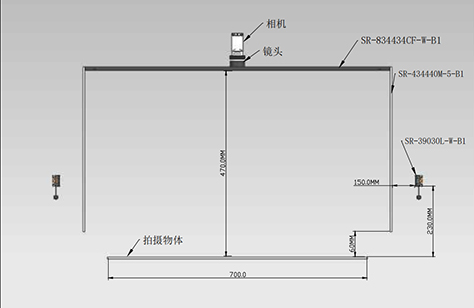

△Light source solutionsLight source solutions

Project AdvantagesProject Advantages

• Solutions are mature. Providing robotics and vision turnkey solutions, one-stop service.Solutions are mature. Providing robotics and vision turnkey solutions, one-stop service.

• High efficiency. 5 slices can be gripped at once with a large field of view of 700mmx470mm and a beat of 2500 slices/hour.High efficiency. 5 slices can be gripped at once with a large field of view of 700mmx470mm and a beat of 2500 slices/hour.

• High stability. Can effectively solve the problem of missed catch and multi-catch with 99.99% yield rate.High stability. Can effectively solve the problem of missed catch and multi-catch with 99.99% yield rate.

• High calibration accuracy and high speed. Calibration accuracy is 0.5mm, overall accuracy ±1mm; calibration can be completed within 10 minutes.High calibration accuracy and high speed. Calibration accuracy is 0.5mm, overall accuracy ±1mm; calibration can be completed within 10 minutes.

• High compatibility. Compatible with a wide range of colors and sizes of glass.High compatibility. Compatible with a wide range of colors and sizes of glass.

• Easy to maintain. 5 minutes to switch to new products.Easy to maintain. 5 minutes to switch to new products.