Applications:Electrical and electric, home appliances, toy manufacturing and other industries

Keywords:SCARA Robot

Related products:

Automatic locking screw machine is used to replace the manual screwing automation equipment, but in the process of screwing often encounter leakage of lock, slippery teeth and floating lock, so how to avoid these situations automatic screw machine?

The industry has a "541 law" that tightening a screw torque applied, respectively 50%, 40% to overcome the friction in the bolt head, threaded vice, and only 10% into the clamping force of the bolt. Based on the above reasons, ADTECH has given SCARA screw machine the functions of torque size control, torque data collection, tightening process detection, etc., and made a lot of targeted development in terms of convenience and humanization of software operation.

Automatic locking screw machine is used to replace the manual screwing automation equipment, but in the process of screwing often encounter leakage of lock, slippery teeth and floating lock, so how to avoid these situations automatic screw machine?

The industry has a "541 law" that tightening a screw torque applied, respectively 50%, 40% to overcome the friction in the bolt head, threaded vice, and only 10% into the clamping force of the bolt. Based on the above reasons, ADTECH has given SCARA screw machine the functions of torque size control, torque data collection, tightening process detection, etc., and made a lot of targeted development in terms of convenience and humanization of software operation.

1. In the main interface, information such as torque, angle, process and condition monitoring in the lock attachment process are made visualized in real time.1. In the main interface, information such as torque, angle, process and condition monitoring in the lock attachment process are made visualized in real time.

2、Support the new tightening and dismantling two process types, set the number of screws and the starting point and other parameters, you can tighten the position and tightening time detection, improve the product yield.

3, the detailed setting interface of process parameters, divided into recognition of silk, locking into, rotary, reverse demolition and re-locking, if it is a simple process scenario, only simple parameter settings.

4、Monitoring of the current is accurate to milliampere, while providing the peak display of forward and reverse. The time period is accurate to 0.1s. Users can intuitively check whether each screw is abnormal in the locking process. Full-scene locking solution

At present, ADTECH can develop a whole locking and attaching integrated solution, including actuator (SCARA screw machine), locking and attaching mechanism (electric batch), vision system, control system, tooling fixture, human-machine interface and machine table, with the characteristics of flexible work station, which can help the terminal to quickly switch between different product lines and quickly use to start production.

ADTECH SCARA screw machine is mainly divided into one-piece type (PR5216) and three-axis type (PTR5512). The former can meet the needs of special processes, in software, structure, core components can be customized; while the latter, is universal, reflecting the advantages of cost performance, can choose to install modular servo locking mechanism to achieve single/multi-station simultaneous locking, double the efficiency, also support external and compatible with the mainstream ordinary, intelligent electric batch, applicable to most of the application scenarios.

On the scene, Huang also shared four kinds of locking solutions, users can choose according to different application scenarios.

PR5216 lock attachment and disassembly type solutions.

2、Support the new tightening and dismantling two process types, set the number of screws and the starting point and other parameters, you can tighten the position and tightening time detection, improve the product yield.

3, the detailed setting interface of process parameters, divided into recognition of silk, locking into, rotary, reverse demolition and re-locking, if it is a simple process scenario, only simple parameter settings.

4、Monitoring of the current is accurate to milliampere, while providing the peak display of forward and reverse. The time period is accurate to 0.1s. Users can intuitively check whether each screw is abnormal in the locking process. Full-scene locking solution

At present, ADTECH can develop a whole locking and attaching integrated solution, including actuator (SCARA screw machine), locking and attaching mechanism (electric batch), vision system, control system, tooling fixture, human-machine interface and machine table, with the characteristics of flexible work station, which can help the terminal to quickly switch between different product lines and quickly use to start production.

ADTECH SCARA screw machine is mainly divided into one-piece type (PR5216) and three-axis type (PTR5512). The former can meet the needs of special processes, in software, structure, core components can be customized; while the latter, is universal, reflecting the advantages of cost performance, can choose to install modular servo locking mechanism to achieve single/multi-station simultaneous locking, double the efficiency, also support external and compatible with the mainstream ordinary, intelligent electric batch, applicable to most of the application scenarios.

On the scene, Huang also shared four kinds of locking solutions, users can choose according to different application scenarios.

PR5216 lock attachment and disassembly type solutions.

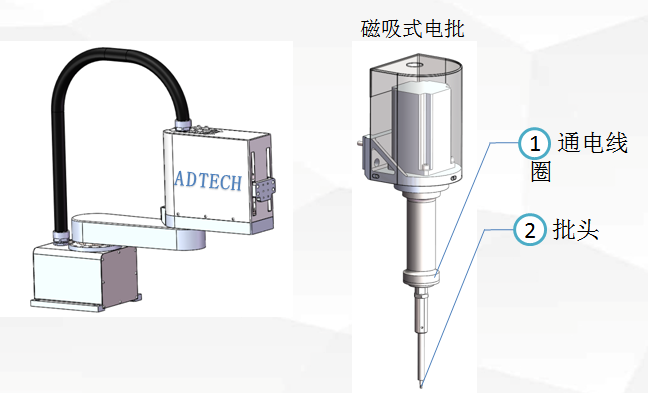

PR5216 lock attached and disassembled type is an all-in-one type with Z-axis as lock attached axis, which is connected by connecting flange and mounting plate. It customizes the structure and software for companies, and is more suitable for end scenarios with special needs for processes.

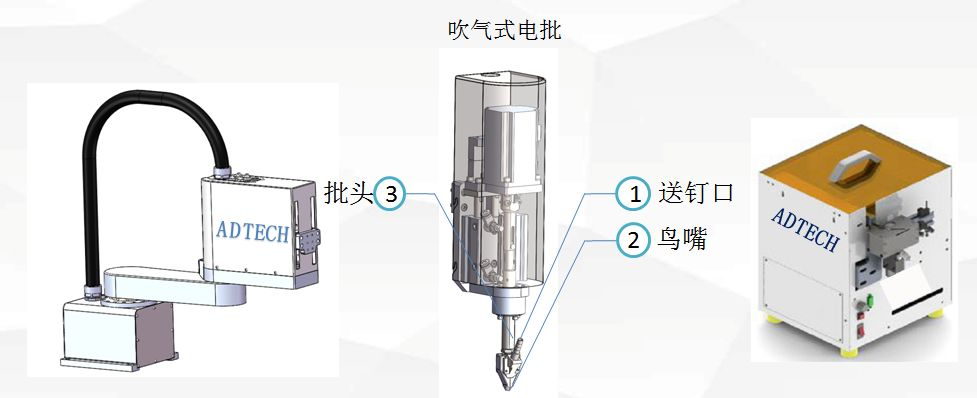

PTR5512 blowing type locking attachment solution.

PTR5512 body + QC400 + demonstrator with blowing type electric batch and feeder; consumables: batch head and bird's beak clamping piece. Staple products: nail feeder and bird's beak part. Suitable for flat, shallow groove, base non-interference locking attachment scenarios, such as hardware jig, industrial electrical products (fine engraving machine jig, contactor, air switch).

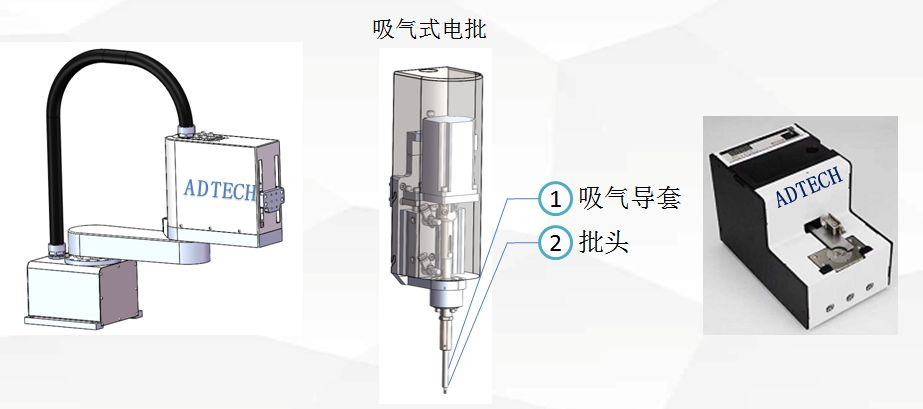

PTR5512 suction locking solution.

PTR5512 body + QC400 + Demonstrator, with suction type electric batch, common supply box, electric batch contains suction guide bush, batch head. Consumables: batch head, customized products: suction guide bush, this solution is suitable for flat and medium slot lock attachment scenarios, such as white home appliances, electronic products shell (TV case, industrial control machine cover, rechargeable cabinet).

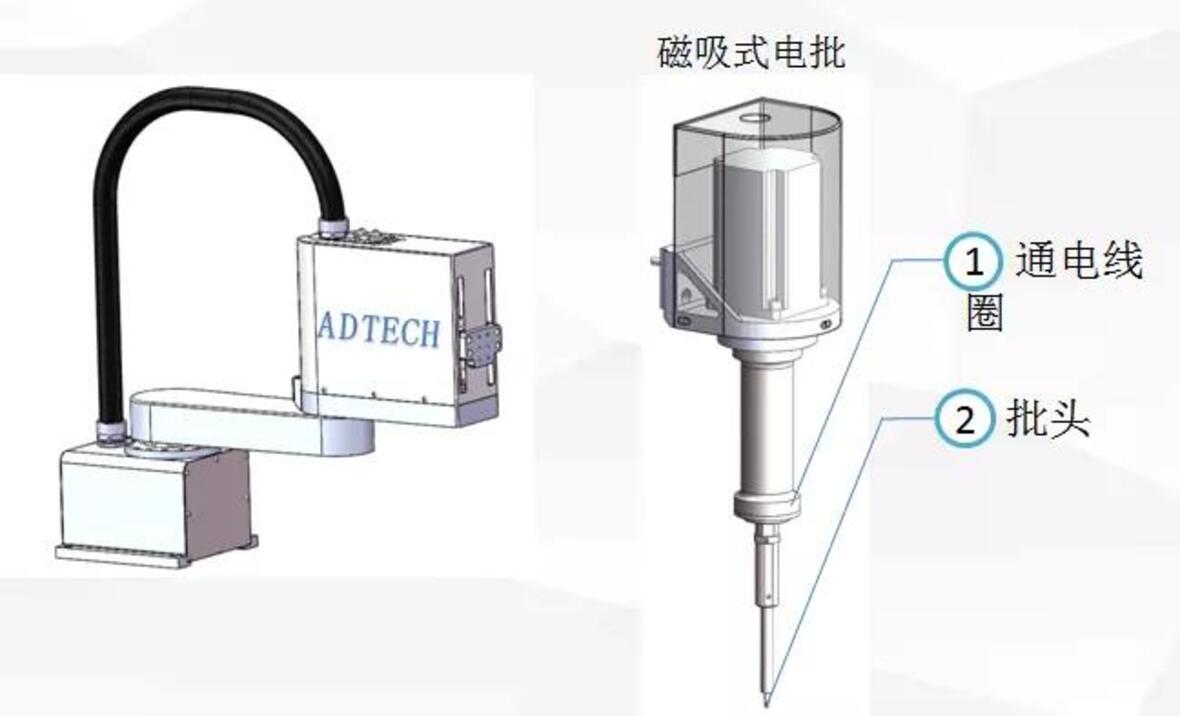

PTR5512 magnetic suction lock attachment solution.

The magnetic suction locking solution is composed with a magnetic suction electric batch, which generates magnetism for screw suction by controlling the circuit on/off of the energized coil. It is suitable for locking scenarios with many interfering positions on flat surfaces, deep grooves and substrates. Based on years of experience in robotics projects and research on the locking process, we are confident to make a good and cost-effective SCARA screw locker.The magnetic suction locking solution is composed with a magnetic suction electric batch, which generates magnetism for screw suction by controlling the circuit on/off of the energized coil. It is suitable for locking scenarios with many interfering positions on flat surfaces, deep grooves and substrates. Based on years of experience in robotics projects and research on the locking process, we are confident to make a good and cost-effective SCARA screw locker.