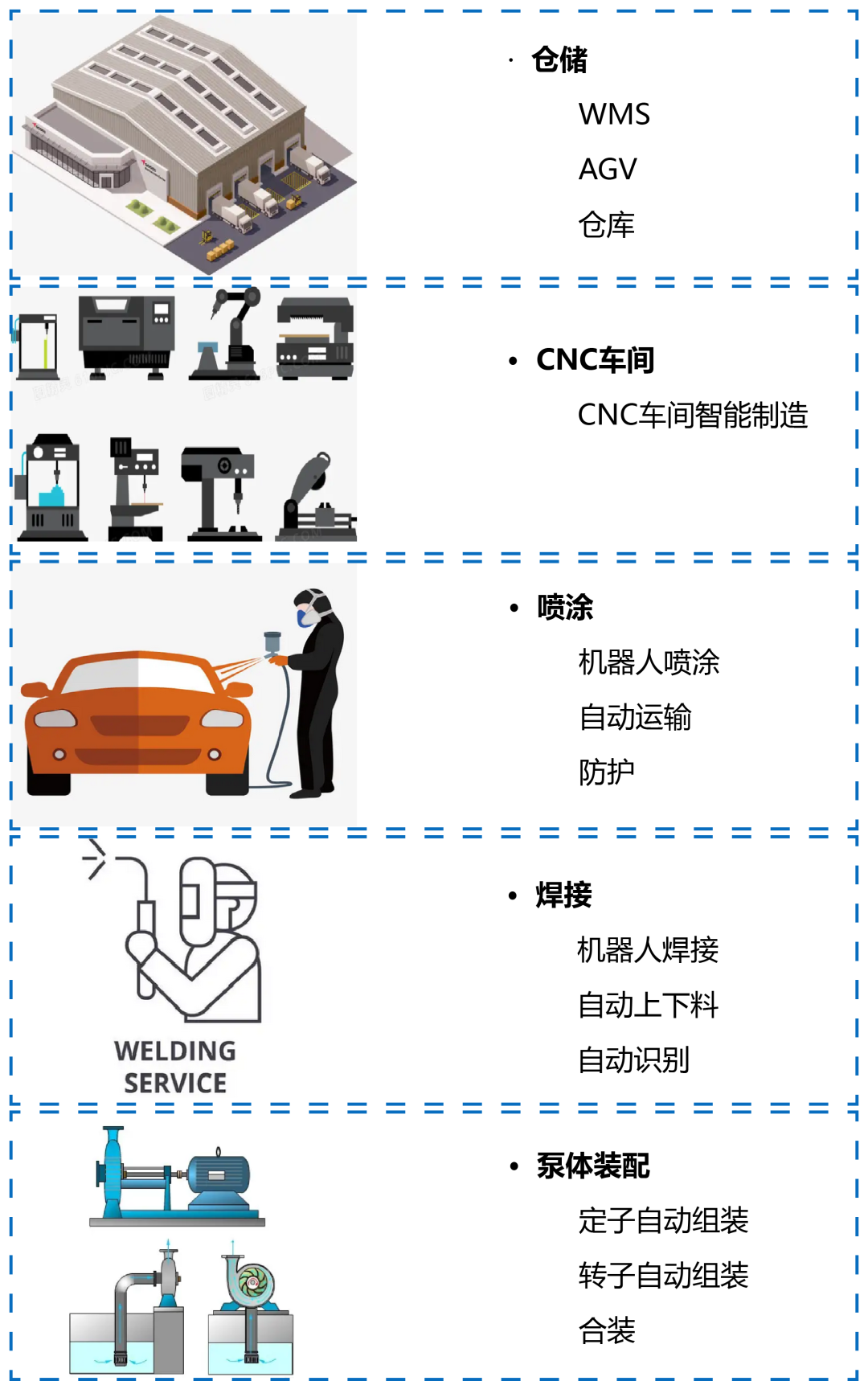

Applications:

Keywords:Raw water, water supply

Related products:

Water industry refers to the industry chain consisting of raw water, water supply, water conservation, drainage, sewage treatment and water recycling. The upstream and downstream of the industry involves valves, pumps, control cabinets and integrated equipment and other industries. At present, the water industry related manufacturing enterprises for industrial upgrading, become a set of intelligent logistics, intelligent storage, intelligent production line, digital processing and production management system in one of the information technology modern industry.Water industry refers to the industry chain consisting of raw water, water supply, water conservation, drainage, sewage treatment and water recycling. The upstream and downstream of the industry involves valves, pumps, control cabinets and integrated equipment and other industries. At present, the water industry related manufacturing enterprises for industrial upgrading, become a set of intelligent logistics, intelligent storage, intelligent production line, digital processing and production management system in one of the information technology modern industry.

I. Water industry product lineI. Water industry product line

II. the water industry production process

III. Solutions and Cases

1 Smart Storage Solutions

Industry Pain Points

Cumbersome inventory management with risk of errors;

Automatic sorting and transportation by AGV to improve work efficiency.

Solution: Smart Storage + AGV

WMS system automatically schedules orders according to MES orders to reduce manual error rate;

AGV automatic sorting and transportation to improve efficiency;

The system automatically in and out of the warehouse management, real-time feedback inventory status.

Cases:控制柜立体库

方式:立库 + 环形库

AGV数量:4 台

机器人数量:1 台

特色:环形仓线边备料,满足当天生产需求

2 水泵解决方案

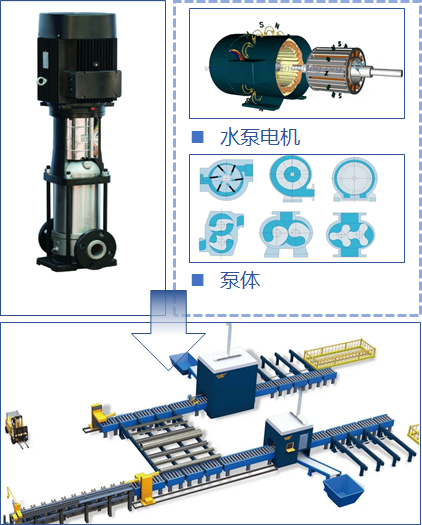

Product Analysis

The water pump consists of pump motor, pump body, etc., which involves motor assembly, pump body processing and pipeline welding.The water pump consists of pump motor, pump body, etc., which involves motor assembly, pump body processing and pipeline welding.

Industry Pain Points

Water pump motor: complex production process, high manual labor intensity, less automated auxiliary measures.Water pump motor: complex production process, high manual labor intensity, less automated auxiliary measures.

Pump body processing:Long production process, difficult to control quality in real time, many processing equipment, high labor costs;

Pipeline welding:Manual welding is labor-intensive, with difficult real-time quality control and high labor costs.

Solutions

Automatic motor assembly:Fully automatic motor assembly by means of conveyor line + assembly station;

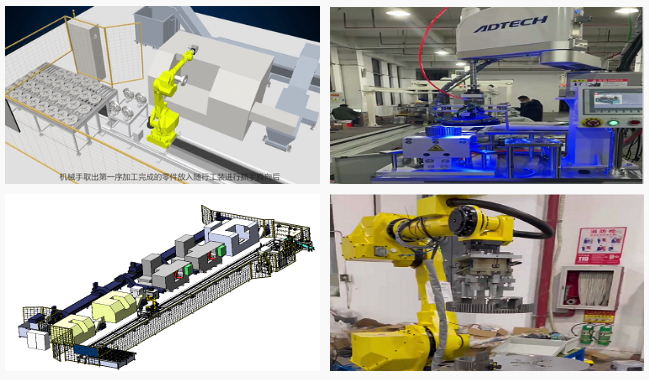

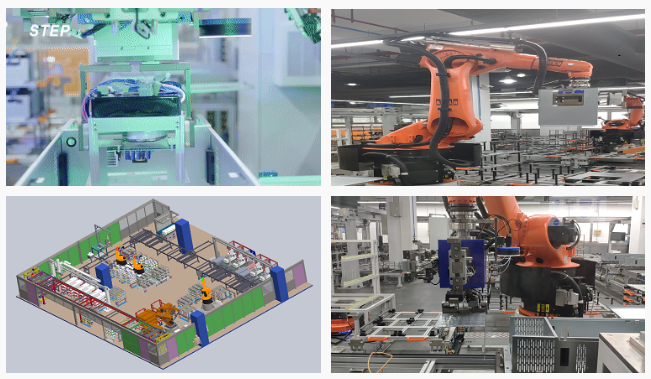

CNC intelligent workshop:Adopt robot loading and unloading to reduce personnel and improve efficiency during pump body processing;

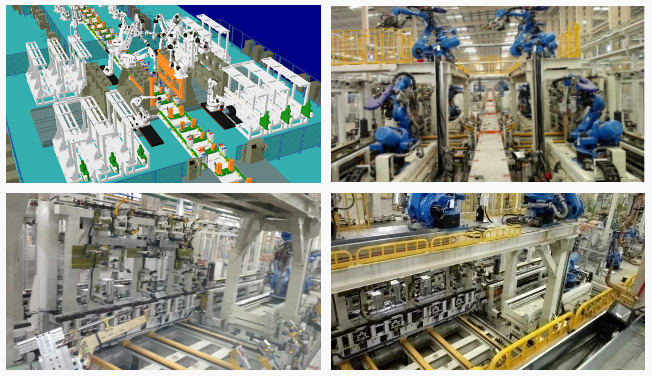

Welding intelligent workshop:Adopt robot to replace manual welding and improve the yield rate.

CNC intelligent workshop case:Machine coupling

Number of machine tools:5 units

Mode:Robot loading and unloading

Processing accuracy:0.05 mm

Number of robots:1 table

Featured:Automatic robot inspection of processing quality

Welding intelligent workshop case:Welding main line

Number of cars:6 units

Time:2013 Year

Production method:Random mixing

Rhythm:85 seconds

Number of robots:126 units

3 Control cabinet solutions

Industry Pain Points

Water pump control cabinet:Generally has a large volume and heavy weight, the current control cabinet assembly is completed by manual production, in the process of assembly, transfer to manual operation brings a lot of inconvenience.

Solutions

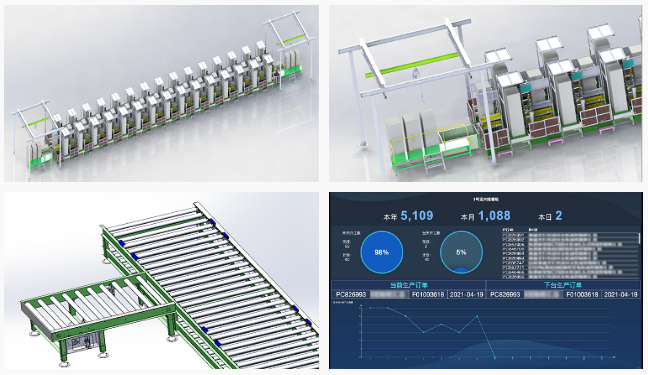

Manual conveying line:Cabinets flow on the conveyor line with manual operation at fixed work stations;

Automatic assembly line:The cabinets flow on the conveyor line and the robots cooperate with the manual to complete the assembly work.

Water pump control cabinet case:Water industry stand-up cabinet assembly line

Load:500 kg

Time:2022 Year

Production method:Random mixing

Workstation:30 Individual

Software:Digital Signage

PLC:STEP

Control cabinet case:Control cabinet automatic assembly line

Model:10Major categories

Time:2020 Year

Production method:Batch switching

Number of robots:6Taiwan

Rhythm:300 seconds

Collaborative robots:2 Taiwan

4 Water Equipment Solutions

Industry Pain Points

Complex production process of integrated devices,Large size of equipment parts, low efficiency of manual installation and high labor cost.

Solutions

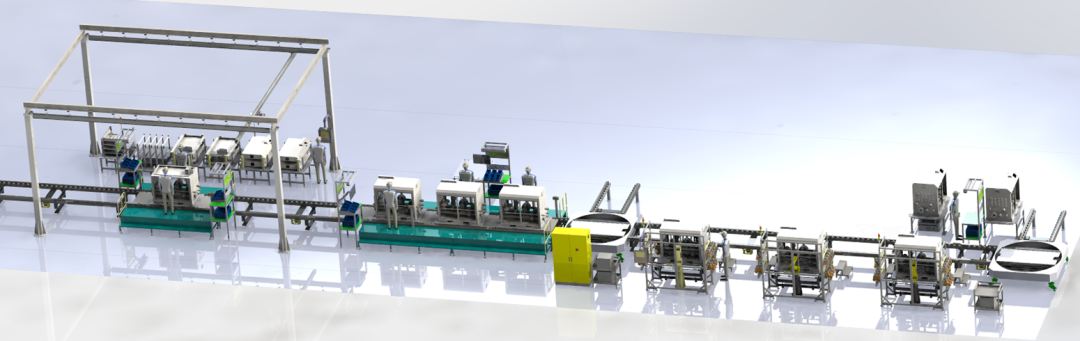

Automatic assembly line:Automatic assembly of the whole equipment by means of conveyor line + robot。

Cases:Backwashing mainframe assembly line

Project Overview

Number of models:3 Models

Time:2022 Year

Production method:Batch switching, order-based flexible production

Rhythm:900seconds

Number of robots:7 Taiwan

Technology Benefits

Robotic Collaborative Flexible Assembly

Precision floating multifunctional gripper

Fully automated production management and data acquisition information system

5 Palletizing solutions

Cases:Tire handling palletizing

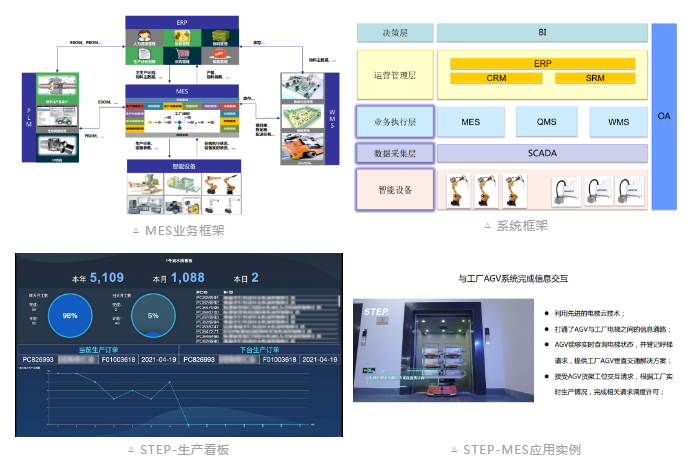

IV. Digital system

V. STEP product introduction