Applications:Rectifier feed-back device AS510, inverter unit AS520

Keywords:Frequency converter

Related products:

With the characteristics of "maximum utilization of electrical energy", the AFE inverter system consisting of rectifier feed-back device AS510 and inverter unit AS520 helps port cranes to complete bulk cargo and container lifting operations, the energy of this powerful CP is not only this, recently successfully applied in Thailand sugar mill honey splitting equipment centrifuges.With the characteristics of "maximum utilization of electrical energy", the AFE inverter system consisting of rectifier feed-back device AS510 and inverter unit AS520 helps port cranes to complete bulk cargo and container lifting operations, the energy of this powerful CP is not only this, recently successfully applied in Thailand sugar mill honey splitting equipment centrifuges.

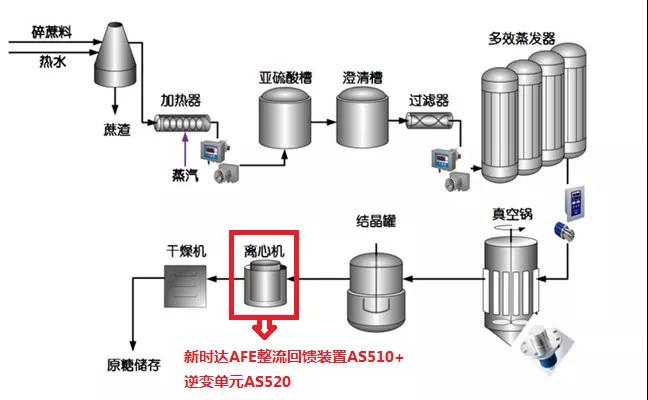

01 Introduction to the sugar mill processIntroduction to the sugar mill process

As the world's leading sugar producer and the second largest sugar exporter, Thailand's local government proposes to strongly support the sugar pillar industry and encourage sugar mills to introduce new machinery and equipment, parts and technology upgrade and maintenance programs to increase local sugar production. In this regard, NewSky's proposal for Thai sugar mills to replace the earlier DC speed control system with high voltage inverters for sugar cane crushers was successfully implemented in 2015. Then this time, NewSky is closely following the key process nodes again, the centrifuge frequency conversion solution for honey splitting equipment is in the latter part of the whole sugar cane sugar production process.As the world's leading sugar producer and the second largest sugar exporter, Thailand's local government proposes to strongly support the sugar pillar industry and encourage sugar mills to introduce new machinery and equipment, parts and technology upgrade and maintenance programs to increase local sugar production. In this regard, NewSky's proposal for Thai sugar mills to replace the earlier DC speed control system with high voltage inverters for sugar cane crushers was successfully implemented in 2015. Then this time, NewSky is closely following the key process nodes again, the centrifuge frequency conversion solution for honey splitting equipment is in the latter part of the whole sugar cane sugar production process.

Figure 1 Basic flow chart of sugar cane sugar productionFigure 1 Basic flow chart of sugar cane sugar production

Video: Centrifuge processing videoVideo: Centrifuge processing video

Video: Video of inverter operationVideo: Video of inverter operation

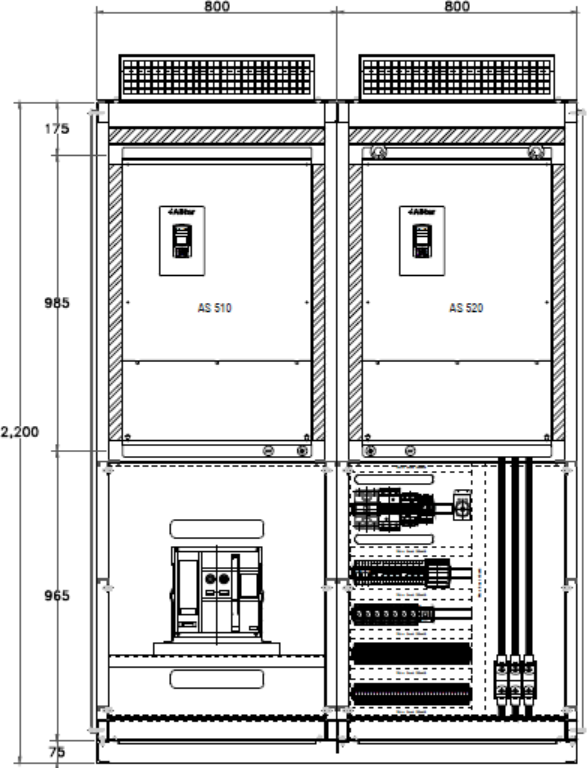

02 AFE variable frequency system configurationAFE variable frequency system configuration

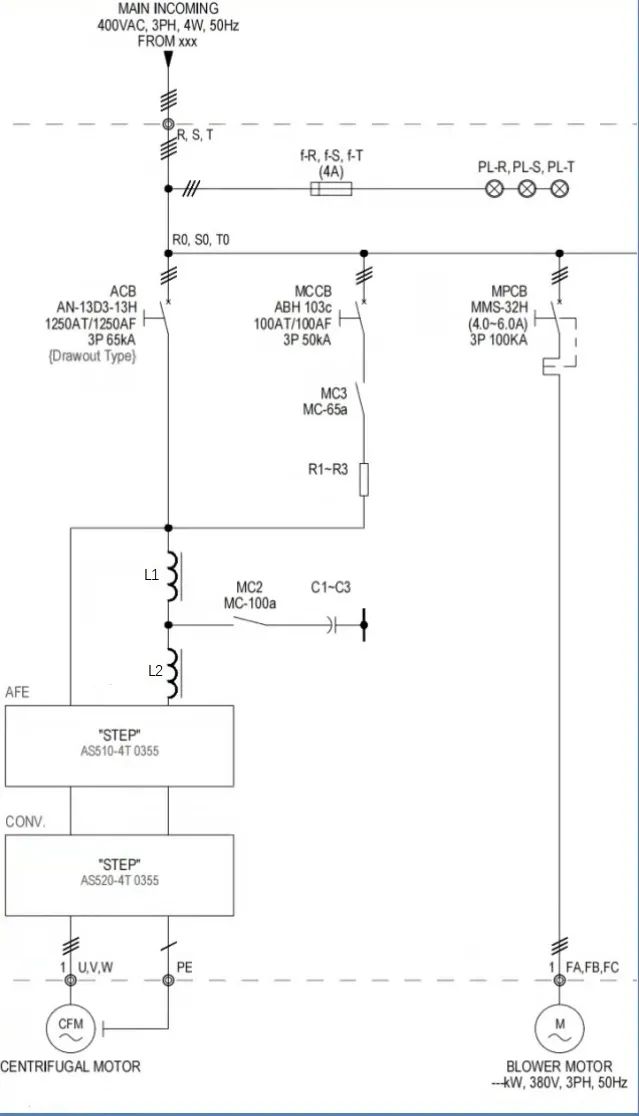

In centrifuges used for honey splitting, due to the relatively large rotational inertia of the centrifuge, regenerative power is generated during deceleration. The AFE variable frequency drive system is used to feed the excess power back to the grid, and the AFE front end is equipped with an LCL filter and a pre-charge circuit. The configuration of the centrifuge motor and the AFE variable frequency drive system is shown in Table 1 belowIn centrifuges used for honey splitting, due to the relatively large rotational inertia of the centrifuge, regenerative power is generated during deceleration. The AFE variable frequency drive system is used to feed the excess power back to the grid, and the AFE front end is equipped with an LCL filter and a pre-charge circuit. The configuration of the centrifuge motor and the AFE variable frequency drive system is shown in Table 1 below:

Table 1 System configuration tableTable 1 System configuration table

Pre-charge circuitPre-charge circuit:

Eliminates inrush current to the inverter and grid.Eliminates inrush current to the inverter and grid.

LCLFilters:

Optimize the quality of the power generated by the entire system and reduce the current harmonics flowing into the grid.Optimize the quality of the power generated by the entire system and reduce the current harmonics flowing into the grid.

AS510(AFE)AS510(AFE):

The AFE is the power supply and feed-back unit of the system, providing constant DC voltage and feeding back power.The AFE is the power supply and feed-back unit of the system, providing constant DC voltage and feeding back power.

AS520 (inverter drive)AS520 (inverter drive):

Multiple drives can be run in parallel to provide reliable drive capability for different loads.Multiple drives can be run in parallel to provide reliable drive capability for different loads.

Figure 2 AS510+AS520 structure layout diagramFigure 2 AS510+AS520 structure layout diagram

Figure 3 Primary diagram of control systemFigure 3 Primary diagram of control system

03 Centrifuge characteristics and technical features of the AFE variable frequency drive systemCentrifuge characteristics and technical features of the AFE variable frequency drive system

Centrifuge characteristicsCentrifuge characteristics

1、Centrifuge loads require higher starting torque and are more difficult to startCentrifuge loads require higher starting torque and are more difficult to start;

2、The centrifuge has a large rotational inertia and generates renewable energy when deceleratingThe centrifuge has a large rotational inertia and generates renewable energy when decelerating;

3、Centrifuge loads require rapid speed-up/downCentrifuge loads require rapid speed-up/down;

4、Sudden load during operationSudden load during operation;

5、Need to start with load.Need to start with load.

Technical features of AFE variable frequency drive systemTechnical features of AFE variable frequency drive system

1、AFE adopts controlled rectification technology, which can realize four-quadrant operation and feed renewable energy back to the gridAFE adopts controlled rectification technology, which can realize four-quadrant operation and feed renewable energy back to the grid;

2、AFE uses vector control technology to improve control performance and reduce control harmonicsAFE uses vector control technology to improve control performance and reduce control harmonics;

3、AFE provides stable DC voltage to the inverterAFE provides stable DC voltage to the inverter;

4、Standard LCL filter to further eliminate harmonics and avoid pollution of the gridStandard LCL filter to further eliminate harmonics and avoid pollution of the grid;

5、AS520 unique GVC control technology, low speed and high torque, eliminating the difficulty of starting the centrifugeAS520 unique GVC control technology, low speed and high torque, eliminating the difficulty of starting the centrifuge;

6、Reduce acceleration and deceleration time, can realize the centrifuge fast start and stop, improve production efficiencyReduce acceleration and deceleration time, can realize the centrifuge fast start and stop, improve production efficiency;

7、Directional torque compensation to effectively cope with sudden load and start with loadDirectional torque compensation to effectively cope with sudden load and start with load。

The motors of centrifuge loads are mostly special motors, especially some old equipment transformation, the site can not provide accurate motor parameters, the new Timeless GVC control algorithm is insensitive to motor parameters, input motor power and voltage parameters to achieve accurate control of the motor. Maintenance of the centrifuge motor after damage is more troublesome, which requires the inverter must have strong protection function for the motor. GVC control algorithm can choose to limit the maximum running current of the motor and provide precise protection for the motor. NewSky's unique GVC control algorithm can realize the control of asynchronous motor and permanent magnet synchronous motor.

The application of this AFE inverter drive system in sugar mill centrifuges provides a new direction for sugar mill centrifuge applications, replacing the traditional energy braking drive method, enabling low speed high torque start with load, and AFE energy feedback rejecting energy waste and improving system efficiency.

The motors of centrifuge loads are mostly special motors, especially some old equipment transformation, the site can not provide accurate motor parameters, the new Timeless GVC control algorithm is insensitive to motor parameters, input motor power and voltage parameters to achieve accurate control of the motor. Maintenance of the centrifuge motor after damage is more troublesome, which requires the inverter must have strong protection function for the motor. GVC control algorithm can choose to limit the maximum running current of the motor and provide precise protection for the motor. NewSky's unique GVC control algorithm can realize the control of asynchronous motor and permanent magnet synchronous motor.

The application of this AFE inverter drive system in sugar mill centrifuges provides a new direction for sugar mill centrifuge applications, replacing the traditional energy braking drive method, enabling low speed high torque start with load, and AFE energy feedback rejecting energy waste and improving system efficiency.