Applications:Food Industry

Keywords:Robot application cases

Related products:

In the food processing industry, with a wide range of products and high production intensity, how can companies free themselves from traditional manual labor and workshop operations to improve food safety and production efficiency?

In automated production lines, the most common type of operation performed by industrial robots is the "pick-and-place" action. In the face of high-precision operations, they are often equipped with machine vision guidance and positioning, which greatly increases the flexibility of production. How about introducing them into food processing lines?

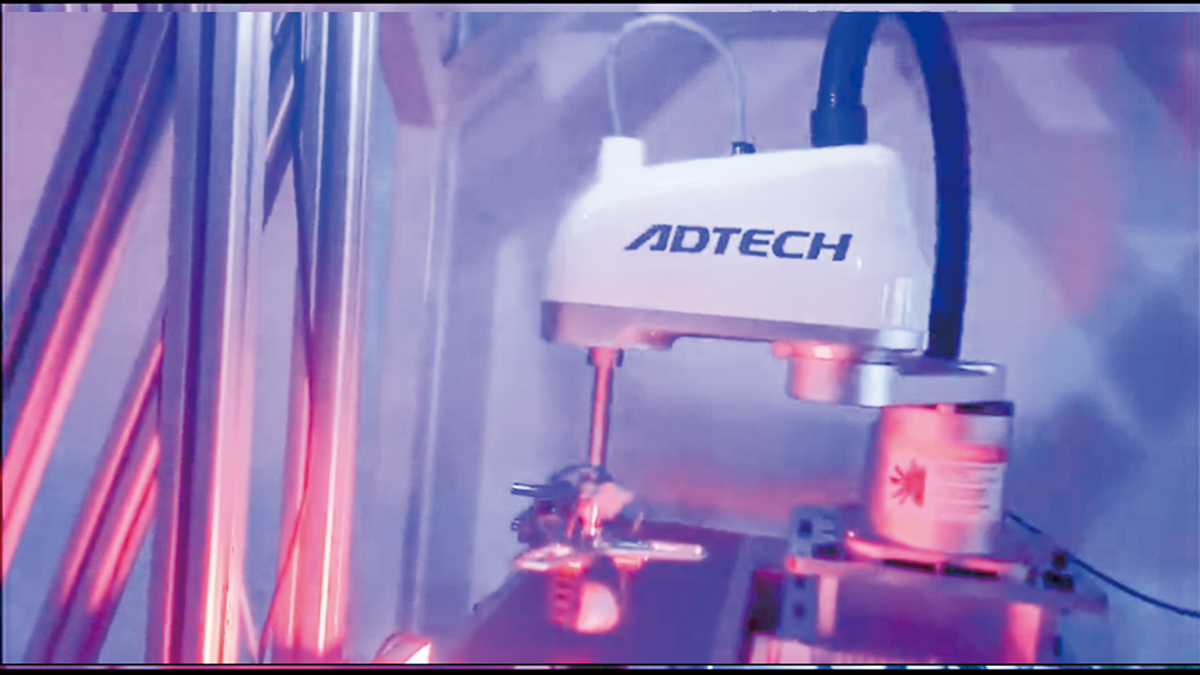

Frozen foods are favored by office workers, and there are automation manufacturers who can easily achieve dynamic high-speed gripping of products with multiple shapes through SCARA and machine vision systems to achieve clean production.

The process design of the solution is not complicated. Vision takes a quick snapshot of the frozen food on the conveyor belt, transmits the position information to the robot, which takes it out quickly, arranges it neatly into the food packaging bag, and then automatically flows into the next station for sealing, and the whole loading and unloading takes only 1 second.

So this solution, what are the technical points to be solved?

Deformation matching, without limiting the size and height of the product,All can precisely locate the product。

In our impression, vision positioning technology is mainly used for grasping and positioning of standard shape products, such as cell phone camera, screen, etc.. But in the food processing industry seems a bit special, for example: the shape of buns can not be completely standardized, which puts forward higher requirements for vision.

Currently on the market, Shenzhen Zhongweixing's AVS vision positioning system, for deformed objects carefully developed vision matching algorithm, no matter how big the difference in object shape, can let the robot accurately grasp.

Stable image processing algorithms

The current mainstream visual image processing technology, the average processing time of a picture will reach 100 milliseconds, so that at most support the efficiency of 10 frames / second capture. In terms of high frame rate application scenarios like frozen food capture, it is completely too late.

The image processing time of AVS vision software can reach within 10 milliseconds, which can meet the efficiency of 90 frames/second capture, with high stability, low false capture rate, the leakage rate is close to 0%, the overall yield reaches 99.9%, and the working beat can reach 3600/hour.

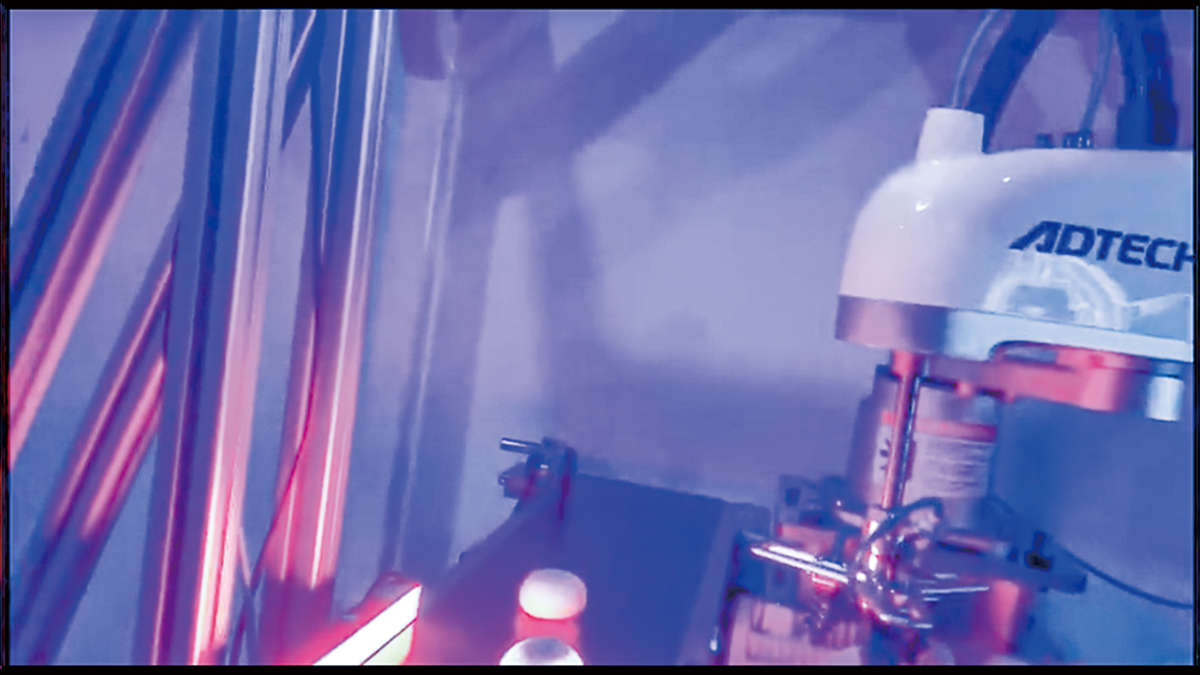

Robot clean design is standard

It is crucial to ensure a safe food production environment. We provide a full set of robot + vision solutions for the food industry, clean design, so that no residue, no oil leakage, from the source to cut off the food safety hazards, and to save space, 10 minutes to complete the product switch.

Automation companies are working together with food companies to create an efficient and safe "food kingdom".