Applications:

Keywords:N95 mask production

Related products:

The whole set of control solution of N95 mask machine is mature, and the existing EtherCAT bus motion control and QX servo drive products are seamlessly connected to achieve "high speed, high precision, high flexibility" production processing. According to the customer's site conditions and requirements, we can develop fully automatic or semi-automatic solutions.

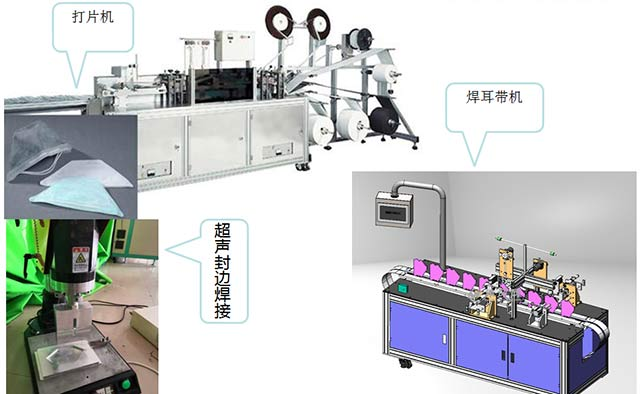

The above-mentioned project of Jiangxi equipment manufacturer focuses on semi-automatic production equipment for folding masks, whose production process can be divided into three parts: sheeting machine, welding earband machine and ultrasonic sealing welding.

According to the characteristics of single machine semi-automation, it can be reasonably combined and divided into sections for production to ensure maximum stage production efficiency and utilization of equipment.

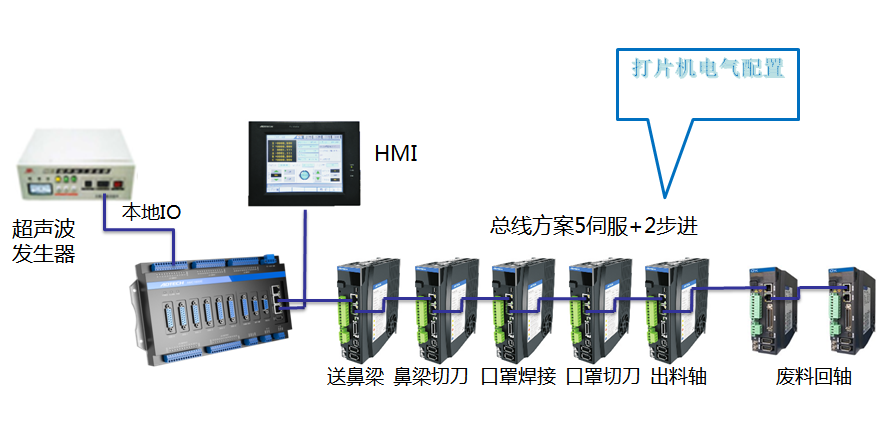

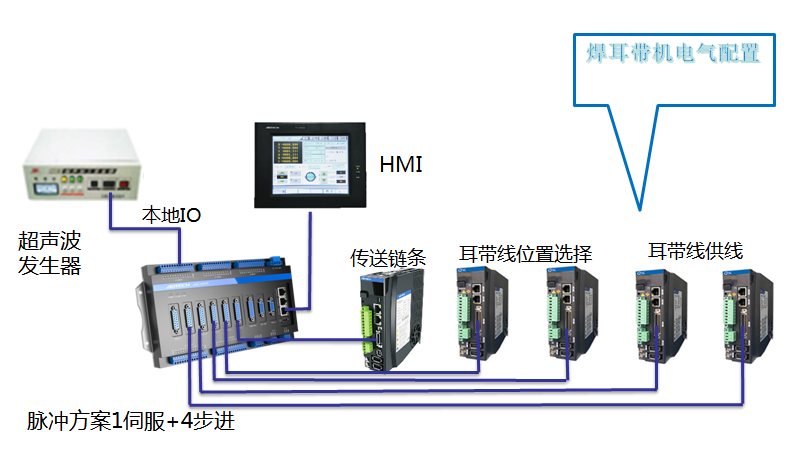

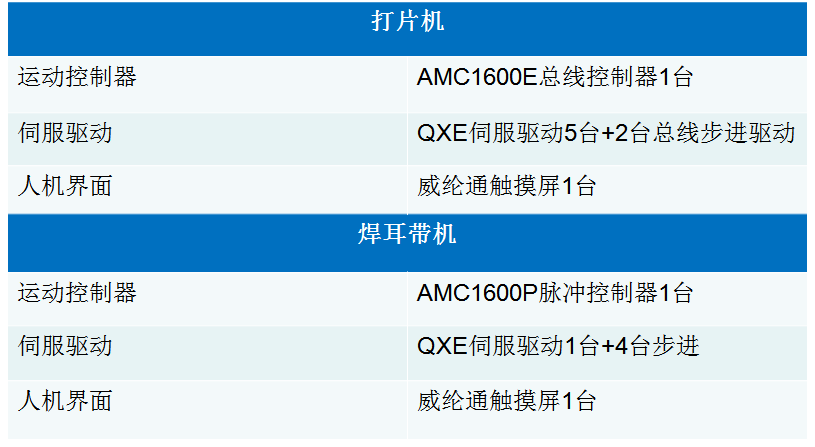

The ZWX solution mainly involves two parts, the punching machine and the soldering lug machine, which adopt bus and pulse control solutions respectively.

N95 semi-automatic mouthpiece machine program electrical configuration diagram

Program Features

·Single machine production efficiency

Separation of sheeting equipment and welding equipment, which is conducive to improving the production efficiency of the product, with sheeting ≥ 200pcs/min.

·Bus + pulse flexible selection

Pulse plus bus mode to facilitate the use of pulse axes in the case of bus multi-axis control mode.

·Servo Response

Using QXE high response servo drive to improve the control level and achieve precise and high speed alignment.

·Programming Software Features

AMC1600E bus controller supports IEC advanced development language to provide cams, flying shears and other key N95 production technology requirements, and then with a powerful library of motion functions that can fully meet the needs of programmers.

·Hardware Configuration

AMC1600E with 36 inputs and 24 outputs on board, without expansion modules, and with its own 6-way pulse interface.

·Stand-alone design advantages

The single machine division station design can reduce the equipment cost and have more applicability.

Solution product list (*provided by Zweixing)

Key Process Technology Explained

Punching piece is divided into manual loading, automatic discharge; nose built-in, automatic press-fold; multi-layer ultrasonic welding; automatic embossing, cutting and other more complex processes, here especially used the electronic cam function of Zong Weixing.

Electronic cam: IEC programming language, direct call cam function library to achieve multi-axis follow spindle synchronous operation, free of debugging, to ensure high speed and high precision fixed length shearing of masks.

For customers, stand-alone devices are easy to develop, and for end users, stand-alone machines are more stable. Semi-automated solutions are not Low, but mainly in the choice of the customer.