Applications:

Keywords:Fully production of flat masks

Related products:

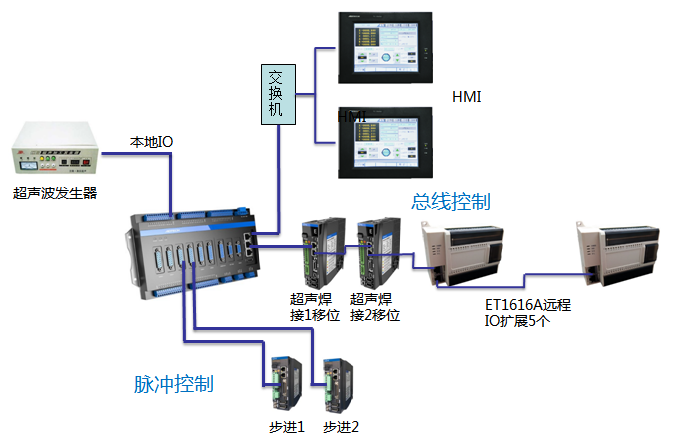

Weixing to AMC1600E bus type controller as the core, design of automatic "one tow two" flat mask machine control solution in a number of customer projects successfully applied.

The solution, using bus control, facilitates the expansion of external IO on the basis of improving running response speed and increasing control accuracy; PLCOpen motion control command library easily meets various motion requirements in mouthpiece production; using IEC61131-3 standard language (IL, FBD, SFC, ST, LD) for programming, giving full play to the flexibility of the ST language, and writing tedious and complex movements in function blocks, making running calls simpler and clearer.

Equipment Introduction

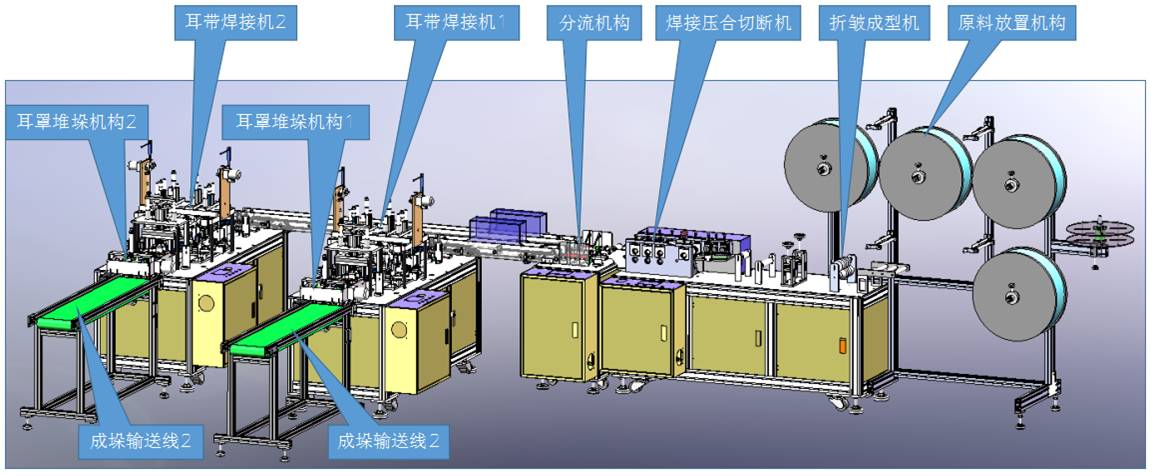

△Equipment composition (click for larger image)

This solution is suitable for the fully automatic production of flat masks, which mainly contains the processes of coil material feeding, folding synthesis, nose band feeding, mask forming, mask cutting, ear upper and welding, finished product discharging, etc. The equipment can also be regarded as the three parts of beating, dividing and welding, and the equipment can complete the whole production process from coil material raw material to finished mask, and the produced masks have comfortable wearing and no pressure feeling. It is also possible to change the turning and dividing motors to cylinder action according to the user's needs, which is conducive to reducing the use of motors.

Electrical parts list

|

PLC |

AMC1600E总线控制器 1台 |

|

Servo Drive |

QXEServo drive 2 sets |

|

Human Machine Interface |

Velcom touch screen 2 sets |

|

Extended IO |

ET1616A expansion IO 5 units |

*Only some of the above are provided by Zweixing

Electrical system configuration

PLC program introduction

The program is mainly divided into three major parts: main program, alarm, and automatic operation.

By using ST language to integrate many complex actions according to the equipment work station for FBD function blocks, the function blocks are called centrally in the three main programs, which not only facilitates the reasonable division of difficult and easy programs in the programming process, but also ensures that too many irrelevant variables are avoided in the process of equipment debugging, thus improving the readability of the program, and finally the main program is run easily by using the multitasking mechanism.

HMIHuman Machine Interface

The HMI human-machine interface is divided into automatic, manual, parameter, function and alarm pages.

Automatic interface: It mainly contains real-time position display of axis position, equipment production count statistics, operation functions such as start, stop, reset, zero return, pause and clear of different work stations.

Manual operation interface: Firstly, it is divided into different work station manual interfaces, and then different work station status interfaces contain manual motor operation page, manual cylinder operation interface and sensor monitoring interface.

Parameter page: Sub-interface according to different work stations, corresponding manual, automatic and zero return parameters can be set under different interfaces.

Alarm interface: including real-time alarm and historical alarm interface, alarm information including date, time and the specific time of occurrence, historical alarm can query the alarm information within one week.