Applications:Lifting industry

Keywords:Inverter solutions

Related products:

AS700 Series Cabinet Type Inverter

Wide range of applications:Product performance is strong, can meet all kinds of operating conditions

Unit modular design:Meet system integrators and OEM customers to design cabinets according to their needs

Wide power, wide voltage range:

3-Phase, 380V - 500V, 250kW - 1400kW

3-Phase, 525V - 690V, 315kW - 1600kW

Complete energy regeneration drive

Single-unit fiber optic communication technology:Power unit and control unit are separated, strong and weak power isolation, improve the system anti-interference ability

Flexible power unit configuration:High-capacity output through parallel connection of power units, improved equipment interchangeability and fewer spare parts

Easy maintenance of equipment:The wheels are installed at the bottom of the power unit, and the cart installation platform is used for operation, which is easy to install and disassemble, and can be configured with maintenance tools to greatly reduce maintenance time

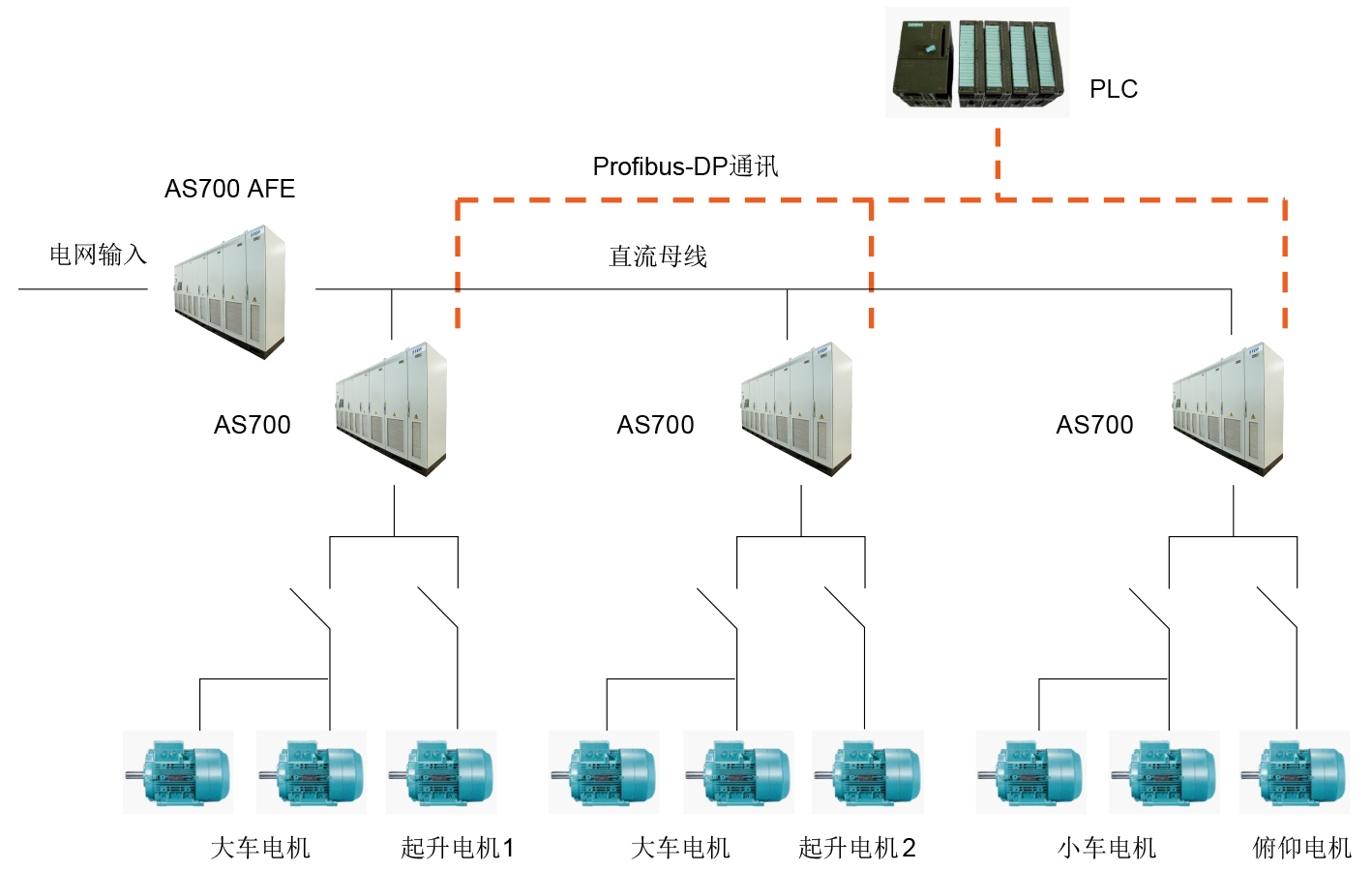

Program Overview

Shore side container loading bridge, referred to as shore bridge, is a kind of overhead movable large crane set on the shore of the terminal, is the main ship loading and unloading equipment of the current professional container terminal, consisting of lifting mechanism, large car structure, trolley structure and pitching mechanism.

Technical Features

Large capacity, low harmonic, high power factor

Realize common DC bus structure, through active rectification and energy return technology, improve product power factor, reduce harmonic pollution, and return the declining generated power to the grid to save power.

Torque memory function

When the brake is closed each time, the output torque of the motor is recorded at this time, and when the brake is opened next time, the torque value of the last memory is output to prevent slipping hook.

Two sets of motor parameters and operation curve switching function

Adopt 1 inverter to drive 2 motors with different working conditions to reduce the input of equipment. The inverter receives the switching signal and immediately completes the switching of motor parameters and operation curve parameters to ensure normal operation of the equipment.

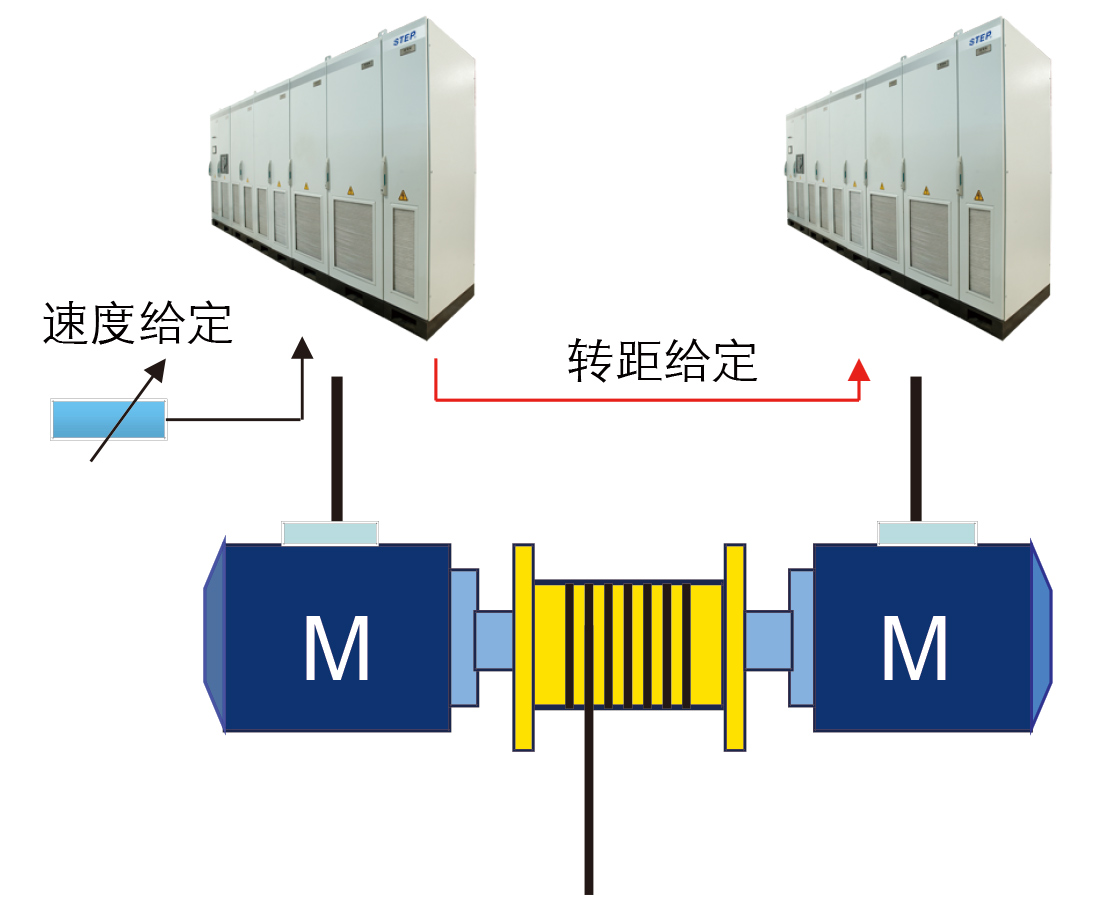

Master-slave control

2 motors are connected coaxially to drive the reel, the host adopts speed control mode, the slave adopts torque control mode; the host outputs torque for the slave through communication or analog mode to complete master-slave control and ensure the same output of the 2 motors.

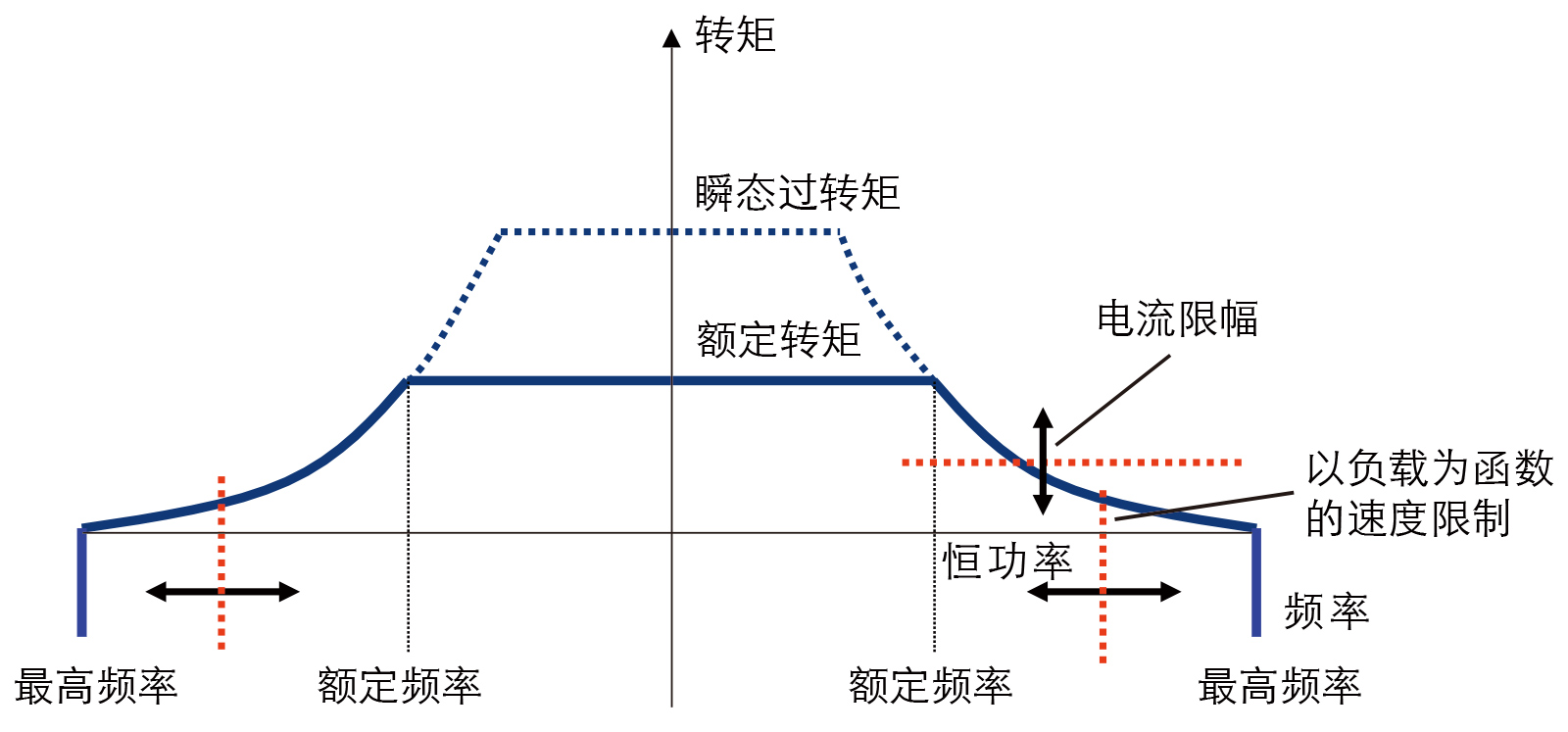

Weak magnetic function

When the rated load is below, the inverter calculates itself to give the highest speed at this time (above the base frequency) to improve the efficiency of the equipment.

High starting torque

V/F control: 150%, 2.5Hz

Without PG vector control: 200%, 0.5Hz

With PG vector control: 200%, 0Hz

High overload capacity

150%, 1 min; 200%, 2s

Solution Block Diagram