A major breakthrough | National Key R&D Program "Industrial Robot Middleware" passed the test

- Views:

- Time of issue:2022-04-01 00:00

A major breakthrough | National Key R&D Program "Industrial Robot Middleware" passed the test

- Views:

- Time of issue:2022-04-01 00:00

Recently, the national key research and development plan - "Industrial Robot Middleware Key Technology and Application Platform Research and Development" passed the rigorous test of Kaiyun Lianchuang (Beijing) Evaluation Center, marking a breakthrough in the "middleware" technology in the field of robotics in my country. The project is led by Jiangsu Jereh Technology Group Co., Ltd., Shanghai STEP Robot Co., Ltd. , Hunan University, Shanghai Jiaotong University, Zhejiang University, the 716th Research Institute of China Shipbuilding Industry Corporation, Yunnan Kunchuan Intelligent Equipment Co., Ltd., Lianyungang It was completed in cooperation with Jereh Deepsoft Technology Co., Ltd.

Most of the existing robot control systems are isolated islands of information with a closed architecture. How to use industrial robot middleware technology to integrate distributed heterogeneous resources, reduce system coupling, and improve the openness and intelligence level of its control system is a key issue for the industrial robot industry. The bottleneck problem that urgently needs to be solved in development.

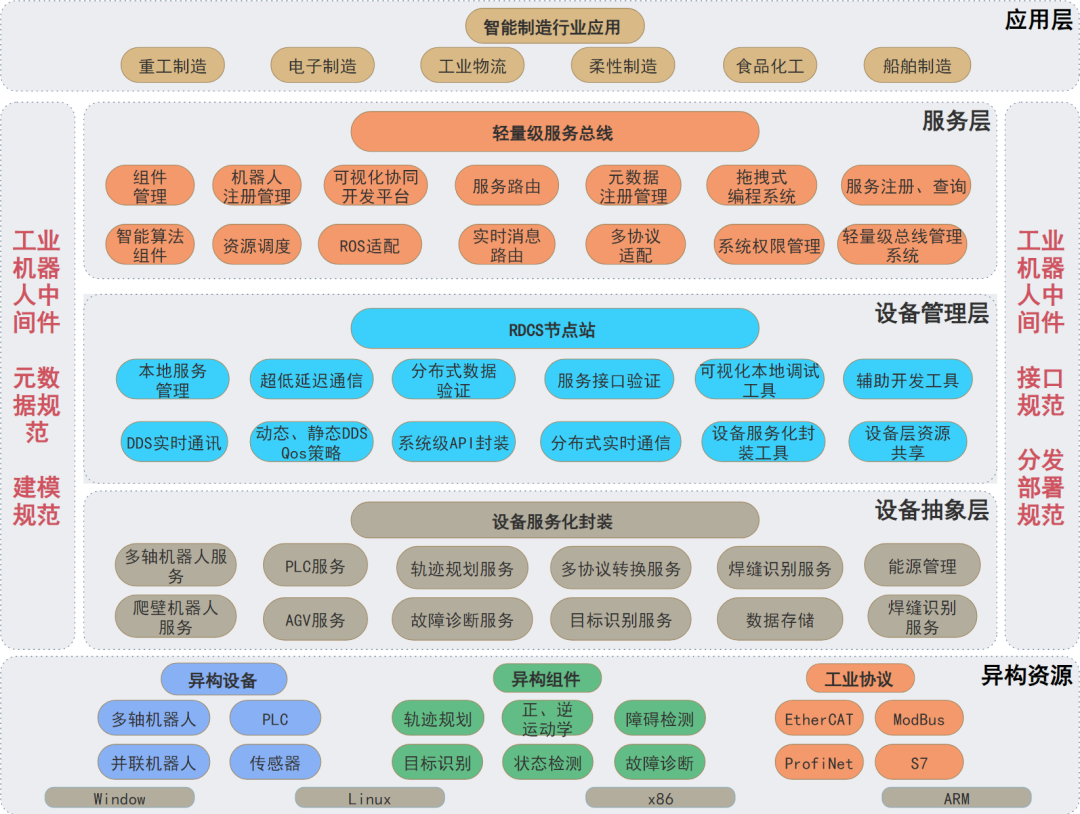

In order to solve the above problems, "middleware" technology emerged as the times require, aiming to develop a service-oriented architecture-based industrial robot middleware and its application platform to realize transparent interaction and distributed collaboration of robotic cyber-physical systems. Using "middleware" technology, heterogeneous robots of multiple brands and different systems can realize seamless collaboration of cross-platform and cross-system design, development, debugging, and deployment, which greatly saves the time required for the integration and deployment of the pre-production line on the industrial site. time.

At the same time, the "middleware" technical framework has a powerful component ecosystem, which can standardize various component interfaces and provide common algorithm components in industrial sites such as vision processing, trajectory planning, and protocol conversion, which facilitates the integration and use of underlying hardware manufacturers. In addition, based on the design concept of the bus, real-time transparent interaction and real-time monitoring of data in the robot production process are realized; code-free orchestration services for robot functions are supported, which greatly reduces the programming work of developers during production line deployment and rapidly improves production. Line intelligence level and manufacturing efficiency.

Middleware Framework of Distributed Control System for Industrial Robots Based on Service-Oriented Architecture

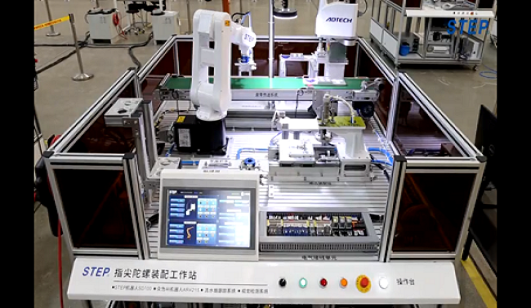

Based on this "middleware" platform, Shanghai STEP Robotics Co., Ltd., Shanghai Jiaotong University and Zhejiang University jointly deployed a visual assembly workstation and a stamping production line, realizing fast, flexible and light-code integration of the production line, which greatly improved the customer's intelligence level of automation and production efficiency. In addition, "middleware" technology has also been put into use in the production lines of ship welding, wall-climbing spraying, and AGV intelligent parking of enterprises such as Jereh and Kunming Shipbuilding. It is foreseeable that in the near future, "middleware" technology will help China's manufacturing to leapfrog development from China's intelligent manufacturing.

STEP robot automated stamping production line

STEP Vision Assembly Workstation

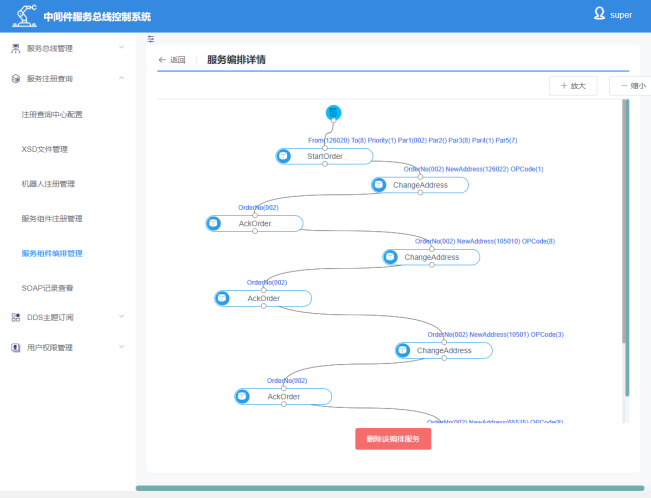

Robot middleware node control station equipment interaction management software

Low-code programming based on service bus service orchestration

Robot based middleware

Construct STEP visual assembly workstation digital twin system

Scan the QR code to read on your phone