Leading market segments | STEP robot welding solutions help leading companies in the all-terrain vehicle industry go abroad

- Views:

- Time of issue:2022-07-07 00:00

Leading market segments | STEP robot welding solutions help leading companies in the all-terrain vehicle industry go abroad

- Views:

- Time of issue:2022-07-07 00:00

Crossing mountains, wading in water, galloping in snow... For off-road people, ATV, UTV and other all-terrain vehicles are undoubtedly a sharp tool for travel and adventure. Since all-terrain vehicles need intense driving, there is a high requirement for the strength of the weld seam. Every time a new workpiece is switched, the manufacturer must do weld cutting and inspection; at the same time, all-terrain vehicles have high requirements for appearance, so the weld seam is formed Beautiful fish scale patterns are required; as the head enterprise of all-terrain vehicles, there are many models, large output, multiple varieties and small batches, and frequent product switching poses high challenges to robot welding speed and ease of use.

Semi-finished products

The high-quality robot brand STEP takes advantage of its technological leadership in thin plate welding to launch a welding solution for all-terrain vehicles , covering the welding of various products such as vehicle frames and panels . With advantages such as simplicity , it has been recognized by leading companies in the all-terrain vehicle industry, and has obtained batch orders. After a period of domestic use, it has gone abroad and achieved large-scale applications in factories in Vietnam and Mexico, helping customers create high-quality sports for the world. Leisure products, expanding overseas territories and consolidating advantages.

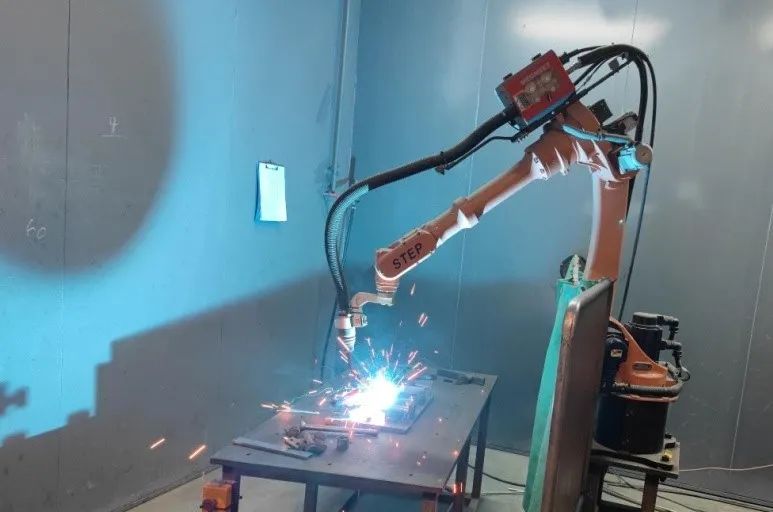

The design of an all-terrain vehicle needs to meet the requirements of strength, stiffness, and dynamic characteristics in order to achieve better fixation and shock absorption. The quality of welding is very important. All-terrain vehicle body panels are mostly made of thin plates, and the welding has the characteristics of "short weld seam, many weld passes, and many empty passes". Due to its weaker ability to resist deformation, welding instability and deformation are relatively easy to occur.

STEP aims at the technical requirements of all-terrain vehicle welding, adopts information feedback, intelligent control and other technologies to improve the adaptive and intelligent level of welding robots , so that it can realize initial welding position recognition and autonomous guidance, real-time welding seam correction and tracking, welding Acquisition of molten pool dynamic feature information, adaptive adjustment of process parameters and real-time control of weld formation.

This leading all-terrain vehicle company located in southwest China is the leader in all-terrain vehicle production capacity and the number one export brand. In terms of the key welding process, the company believes that there is still room for improvement in reducing welding cracks and improving weld fusion. At the same time, it also has a high willingness to replace manual welding with robots.

Facing the double dilemma of the surge in production capacity and the difficulty of recruiting welders, the company introduced the STEP all-terrain vehicle welding solution starting from the product structure, manufacturing process and research and development methods. Due to the stable performance of the STEP robot welding workstation on the production line, it can work 24 hours a day, greatly improve the welding quality and production efficiency of vehicles, reduce labor costs, and effectively support customers' daily production capacity.

It is worth mentioning that the cultural level of local general workers is not high and the turnover rate of employees is high. In order to allow such general workers to get started quickly, STEP is responsible for on-site training engineers. , On the other hand, by compiling catchy formulas, new employees can master the robot working skills proficiently only after half a day of training by the team leader, so that users can completely get rid of the difficulty of recruiting welders.

This cooperation with the head enterprise of all-terrain vehicles has verified the STEP robot welding solution, established the brand awareness of STEP in the all-terrain vehicle industry, and consolidated the leading edge of STEP robots in the field of thin plate welding.

Scan the QR code to read on your phone