On August 3, 2022, Zhou Guangxing, deputy general manager of STEP and general manager of the Robot Division, was invited to attend the 2022 (Fifth) High-tech Robot Integrator Conference, delivered a keynote speech on "Smart Manufacturing Solutions Led by PAC", and shared STEP Give full play to the core technical advantages of mastering PAC, servo, frequency conversion, motor, encoder and other motion control and industrial robots, and empower partners with leading intelligent manufacturing solutions in multiple market segments.

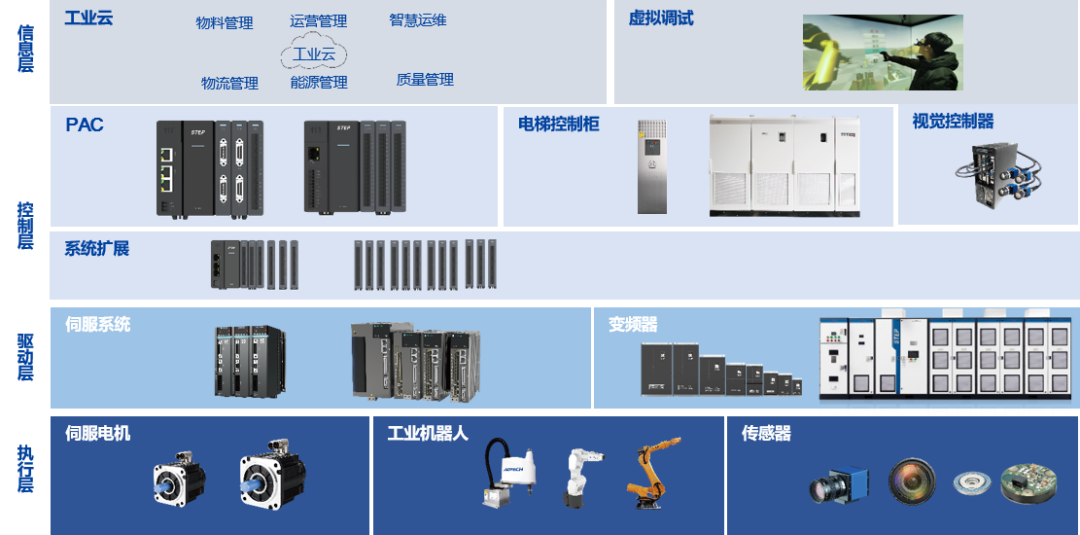

Zhou Guangxing pointed out that with the implementation of intelligent manufacturing in more and more subdivided industries, system integrators are faced with the dilemma of diverse application scenarios and difficult process realization, and urgently need the support of core technology of motion control and robotics. At the same time, domestic substitution is moving towards the deep water area, and companies like STEP that have mastered the core technologies of motion control and industrial robots have begun to highlight their market advantages. PAC (Programmable Automation Controller) is the key to the solution. It is used in conjunction with servos, motors, encoders, human-machine interfaces, and SCARA and six-axis robots to meet flexible and flexible production requirements.

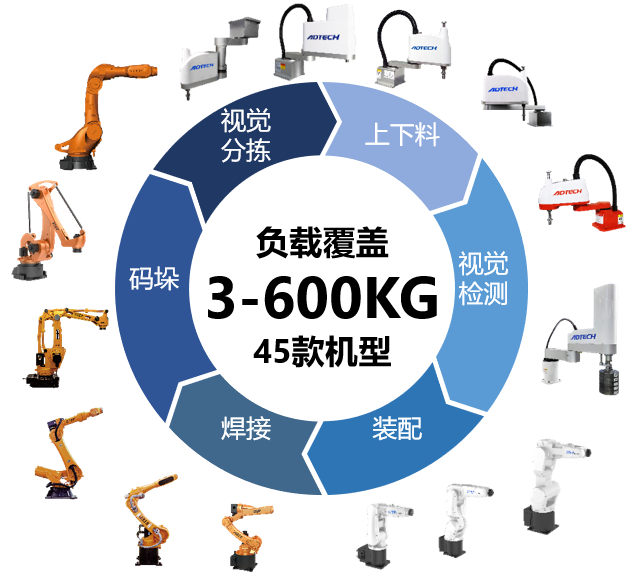

Zhou Guangxing said, "It is precisely because of the STEP robot's constant pursuit of technological innovation that we are at the forefront of the industry's development. " Stable; adopting low-frequency vibration suppression technology, the robot has a longer life, and has taken the lead in the industry to pass the MTBF20,000-hour certification; teaching-free autonomous path planning realizes intelligent and easy-to-use robots. The performance of the STEP robot has achieved parity with international brands. Among them, the beat rate of the palletizing robot has exceeded 1200 packs/hour . Under the condition of full load and full speed, it can still maintain the excellent characteristics of low operating noise and high . After 12 years of market verification, STEP four-six-axis industrial robots have formed a total of 45 products with a load range of 3kg-600kg .

In terms of robot manufacturing, the STEP robot super factory realizes robot manufacturing robots. Its high-precision assembly capabilities, high-level raw materials and factory inspection can effectively guarantee the high quality of robot products. At present, the annual production capacity of the factory together with the Shenzhen factory has reached 20,000 units. This year, in a market environment where foreign brands are out of stock and stock is competitive, STEP targets the lithium battery industry, and a variety of heavy-duty robot products have a delivery time of 30 days, helping the high-growth industry to expand production capacity.

In terms of cooperation strategy with integrators, STEP cooperates with integrators who are familiar with user application scenarios and key processes, leads intelligent manufacturing solutions with PAC, provides users with efficient and easy-to-use solutions, jointly develops customers, and introduces With the help of capital, sign a long-term strategic cooperation, build an ecological chain, and jointly become bigger and stronger. At present, it has taken the lead in market segments such as lithium batteries, photovoltaics, 3C, steel structures and rubber tires.

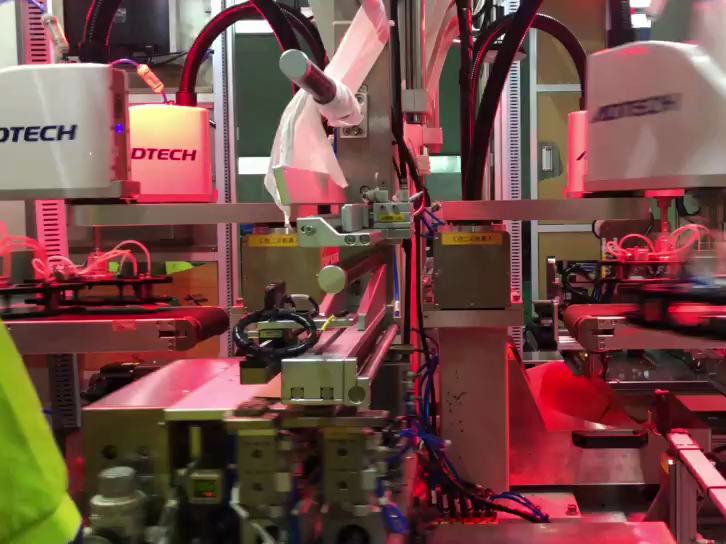

Energy storage battery cell visual grasping and loading

Energy storage battery cell visual grasping and loading

The lithium battery market is showing high growth and is entering the TWh era. The continuous acceleration of lithium battery technology iterations and different module design structures have put forward higher requirements for the automation of lithium battery production. Based on the rich motion control, robot product matrix and technology and service advantages, STEP can provide the lithium battery industry with automation solutions from coating machines, winding machines, stacking machines, die-cutting machines and other equipment to production lines and factories.

In the rubber tire industry, STEP has completed the expansion from the first brand of frequency converters for internal mixers to the leader in the rubber tire laser engraving industry. With the SR series six-axis robot as the core, STEP has created an intelligent solution for tire laser engraving for enterprises such as Zhongce Rubber, which has eliminated the phenomenon of cycle brand overflow, reduced the repair rate, and improved product quality; completely bid farewell to cycle brand, The material, labor and error correction costs caused by the steel small ticket process have increased the utilization rate of the vulcanizer and realized cost reduction and efficiency increase; it can automatically interact with the production MES system, automatically generate data, and open up the MES and WMS systems to improve tire production. The level of digitalization and intelligence in manufacturing.

In the power tower and construction steel structure industries, it provides STEP arc welding robot workstations, through robot laser guidance and parameterized programming, it realizes the automatic welding of workpieces on site in small batches of various varieties, and has won the recognition of leading enterprises in the industry.