Ferrosilicon is a compound that is widely used as a deoxidizer and alloying agent in industrial production such as steel and foundry, and is an important part of industrial production. The smelting of ferrosilicon is made by smelting coke, steel shavings, quartz (or silica) in an electric furnace. The refining of ferrosilicon consumes a lot of energy and generates a lot of dust. In order to avoid the pollution of dust to the environment and improve the energy utilization rate, high-quality high-voltage frequency converter is an indispensable driving equipment in the electric furnace dust collector.

STEP continues to help ferroalloy manufacturers upgrade and transform

A ferroalloy factory in Lanzhou, Gansu Province is a key enterprise in local ferrosilicon smelting, and has established a long-term cooperative relationship with STEP. In order to solve the contradiction of insufficient production capacity, the company has upgraded the ferrosilicon electric furnace system. In line with the goal of one-step improvement and overall improvement, the improvement of dust removal effect has also been included in the key considerations.

After some evaluation, the company decided to replace the fan, motor and its driving frequency converter in the dust collector. Based on the good application results of past products, customers choose STEP inverters to replace existing brand inverters without hesitation. The company believes that after more than ten years of comprehensive comparison of production, use and after-sales service, the STEP inverter has more stable operation, lower failure rate and better service.

Now, let's take a look at the specific performance of the STEP inverter in this transformation!

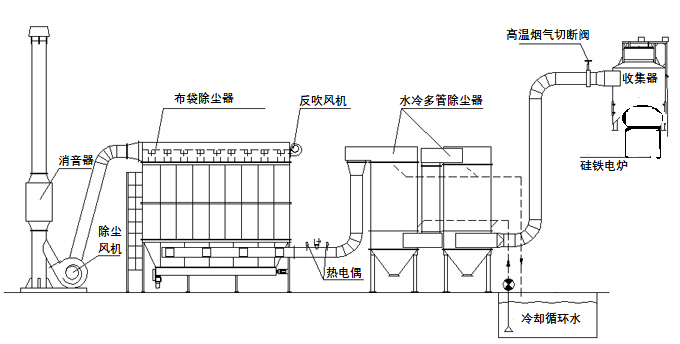

Schematic diagram of process flow of large-scale reverse blowing bag filter

Process flow of back blowing bag filter

In the production process of ferrosilicon electric furnace, there are processes such as charging, power transmission and melting, oxygen blowing, reduction, slag flushing and iron removal, etc. The entire electric furnace smelting cycle is about 90 minutes, of which the power transmission melting and oxygen blowing stages account for about 60% of the entire process time. The high-temperature dust flue gas generated at this time is cooled by the water-cooled dust collector, then enters the reverse air bag filter for purification, and then is discharged into the atmosphere. Demand adjusts the operating frequency to achieve efficient energy use.

Inverter system configuration

In the dust removal system upgraded in this project, the reverse blower adopts STEP AS450 series vector-type low-voltage inverter, and the adaptive power of the inverter is 280kW, and the dust removal fan adopts AS800 series 1250kW high-voltage inverter. Previously, 4 STEP AS800 series high-voltage frequency converters have been successfully applied in previous transformations of the manufacturer.

Dust removal high voltage frequency converter is running

Advantages of STEP AS800 high-voltage inverter drive

· Power factor above 0.95, no harmonic interference to the power grid

· The efficiency of the whole machine is high, and the operating efficiency at full load is as high as 96%, which improves the energy utilization rate

The frequency converter drive can freely adjust the speed according to the process requirements, rejecting the waste of electric energy

It has the function of flying start to meet the needs of fan and pump loads to achieve a smooth restart without stopping

· Frequency conversion non-disturbance synchronous switching function to realize power frequency start-up of high-power fan pump loads

· Power failure battery life and power failure restart function, to ensure the normal operation of the equipment in the case of instantaneous power failure of the power grid

Support unit bypass function, automatic bypass operation when a single unit fails, to ensure the continuity of equipment operation

· Customize the VF curve function to meet the start-up requirements of various fan loads

Free choice of various control methods, panel, terminal, various communication control

· Equipped with a variety of power frequency bypass systems, which can realize power conversion switching according to customer process requirements

· Perfect fault self-diagnosis display function, support virtual oscilloscope and event record display

· Frequency conversion speed regulation pressure closed-loop built-in pid process closed-loop control, stable voltage control, avoiding valve adjustment

· Frequency conversion speed regulation realizes soft start of the system, reduces start-up impact and prolongs the service life of equipment

· Support permanent magnet synchronous / separately excited synchronous motor drive, no need to change hardware configuration

· High-voltage group control system, supporting remote centralized monitoring/control