Where is the breakthrough of local arc welding robots? STEP successfully developed market segments

- Views:

- Time of issue:2022-09-13 00:00

Where is the breakthrough of local arc welding robots? STEP successfully developed market segments

- Views:

- Time of issue:2022-09-13 00:00

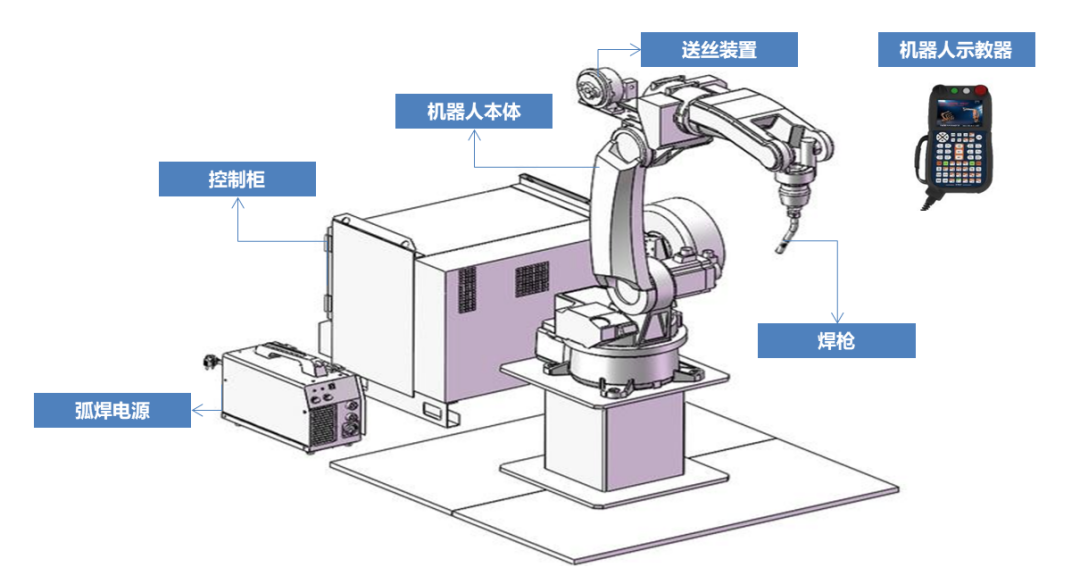

Welding is like the "tailor" of industrial manufacturing. It firmly combines the components that need to be spliced together by arc welding. The perfection of the welding process has a decisive impact on the quality of the final product. In the past, the scene of welding in the factory - dust, arc light, metal spattering, the working environment of welding workers is extremely harsh, and the emergence of arc welding robots has changed this situation.

The six-degree-of-freedom hollow robotic arm wields a welding torch, and with the cooperation of peripheral equipment, it can struggle day and night. In today's factory production line, the meaning of human existence is to dominate the machine. With the introduction of arc welding robots, the quality and stability of welding can be guaranteed, the working conditions of workers will be improved, the production efficiency of factories will be further improved, and the industrial production mode will become more flexible...

Basic composition of arc welding robot

#01 The arc welding robot first entered the automotive industry and the general industrial demand exploded.

Since the 1990s, with China's introduction of advanced manufacturing technology and production equipment, China's automobile manufacturing level has taken the lead in evolving from workshop-style production to large-scale production. Arc welding robots of foreign brands have taken this opportunity to enter China in large numbers, seizing a large market share. part of the market. In the 21st century, China began to accelerate the construction of automation, focusing on the field of robots, and its own brand arc welding robots ushered in a period of rapid development.

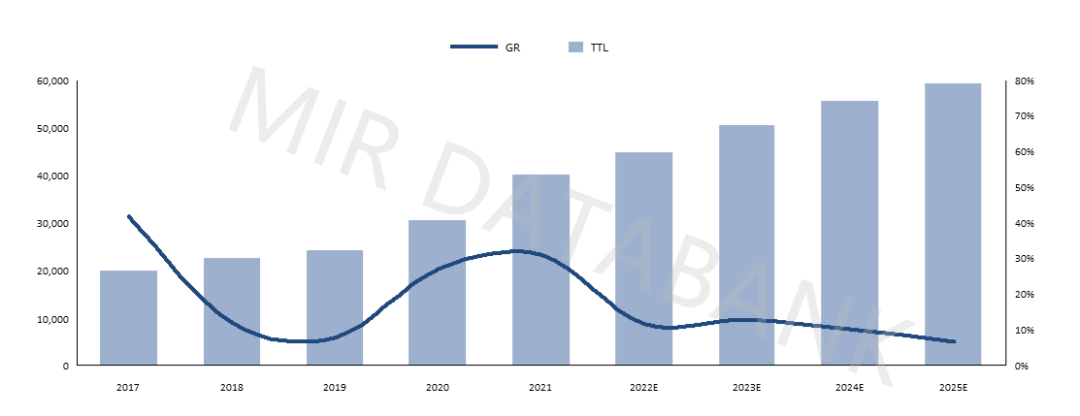

Before 2017, the domestic welding market was driven by metal processing and other businesses in the automotive industry. Among all the downstream application industries of arc welding robots, the automotive industry accounted for more than 55%, mainly used in automotive chassis, seats, and body structures. Welding of parts and other parts. According to data from MIR DATABANK, the sales volume of China's arc welding robot market exceeded 20,000 units in 2017, a year-on-year increase of 41.8%. But at that time, foreign brands almost monopolized the market by relying on their customer relationships with car companies and mature technology. Running-in, the service life is short, so the competitiveness in the overall market is weak, and the development is relatively stable.

From 2018 to 2019, the prosperity of the domestic auto industry declined, and the growth rate of the corresponding arc welding market slowed down significantly. A group of domestic manufacturers emerged in the country with the advantages of being able to quickly respond to the market with local resources, sought opportunities in the general industry, and cultivated a group of customers to lay the foundation .

Since 2020, China's welding market has ushered in a new round of rapid growth. On the one hand, the demand for welding equipment in industries such as hardware furniture, two-wheelers, and fitness equipment related to export has increased significantly. In 2021, general industrial arc welding robots will be shipped. accounted for half of the total shipments. Investment in medium and heavy plate industries such as construction machinery, construction machinery, ships, and containers has also increased, and there is a strong demand for welding robots; People" gradually changed from a trend to a rigid demand, and the development of the general industrial arc welding market accelerated. According to MIR DATABANK data, the market size of arc welding robots in China will exceed 40,000 units in 2021.

Overall Market Size and Forecast of Arc Welding Robots in China from 2017 to 2025 (Taiwan)

(Data source: MIR DATABANK)

With the continuous update and iteration of technology, the arc welding robot technology of domestic brands has become more mature, the cost has been continuously reduced, the price has been continuously reduced, and the market recognition has also increased year by year. Coupled with the promotion of domestic intelligent manufacturing policies, it is expected that the market will maintain stable growth in the future, and the competition between domestic and foreign robot manufacturers in this field will also become more intense.

#02 Foreign capital occupies a large market and domestic capital has huge development potential

At present, the robots used in China are mainly divided into Japanese, European and domestic brands. According to MIR DATABANK data, foreign brands accounted for more than 64% of the arc welding robot market in 2021, still occupying a large part of the market share.

Market structure of arc welding robots in China in 2021 (Taiwan)

(Data source: MIR DATABANK)

On the one hand, foreign leading industrial robot companies have established a solid cooperation system with domestic and foreign mainstream digital welding machine manufacturers such as Fronius, Lincoln, Megmeet, Aotai, and Kaierda; The development of application technology, such as laser positioning, 3D vision, etc., is making efforts in markets with high concentration of major customers, such as auto parts, construction machinery, containers, construction machinery and other industries, so it has a relatively large market share.

Some foreign manufacturers not only have arc welding robot body equipment, but also produce supporting welding power supply, wire feeding mechanism and welding torch of their own brands, so the stability and coordination of the equipment are good, and the difficulty of debugging is low. With product performance and first-mover advantages, it has been widely used in auto parts and general industrial fields.

Domestic manufacturers are mainly represented by STEP, and the downstream industries are mainly concentrated in metal processing markets such as two-wheelers, fitness equipment, hardware furniture, etc. After years of technical precipitation, the product performance of domestic arc welding robots and peripheral equipment manufacturers has been greatly improved. At the same time, the cost is also falling sharply, the market recognition in the civil industry has been significantly improved, and the tentative application of domestic arc welding robots by small and medium-sized enterprises has increased. And benefiting from the rapid development of new energy vehicles in recent years, the production of battery packs, motors and other components has accelerated the introduction of arc welding robots, and the application market for arc welding robots has further expanded. With the promotion of intelligent manufacturing and the rapid development of the new energy industry, small and medium-sized enterprises have increased demand for domestic brands with higher cost performance. It is expected that the market share of domestic brands will grow steadily in the next few years.

#03 Improve product features to prepare for high-end field

Under the situation that foreign capital occupies a dominant position in the domestic arc welding robot market, domestic manufacturers still have a lot of room for improvement. So for domestic arc welding robots, where is the future breakthrough?

Precipitate the general industrial market and explore more subdivided fields

In recent years, the downstream automation investment in the general industrial market has continued to increase. The fields of two-wheelers, medical equipment, fitness equipment, cabinet shelves, hardware furniture and other fields have begun to accelerate the penetration of domestic arc welding robots. Although the demand in these fields is relatively scattered, and the price sensitivity and service timeliness requirements are high, MIR Rui Industry believes that this should be the cornerstone of domestic arc welding robot brands accepting market experience and depositing technology. Subsequent domestic manufacturers should explore more. Subdivide fields, open up more channels, cultivate more customers, and polish the "sharp weapon" in hand.

Among the more prominent domestic brands nowadays, STEP has always insisted that "the decisive opportunity for domestic brands lies in market segments " , and has been deeply involved in industries such as power towers, building steel structures, all-terrain vehicles, and construction machinery. Taking the power tower as an example, STEP uses innovative parametric programming and laser-guided welding technology to build a STEP tower foot welding intelligent robot workstation, allowing users to input simple workpiece size information, and the robot can realize the welding seam through the laser recognition system Acquisition of the trajectory automatically calls the parameters of the welding expert library, so as to realize teaching-free and intelligent welding.

STEP tower foot welding robot

Increase product investment and multilateral cooperation with peripheral suppliers

In the fields of medium and thick plates such as construction machinery, steel structures, rail transit, and ships, not only the equipment accuracy and stability of welding robot manufacturers are required, but also peripheral technologies such as torque sensing, multi-layer and multi-channel, laser guidance, welding, etc. There are requirements for seam detection and polishing of welding function package. It is precisely because of the support of world-renowned manufacturers behind foreign brands, such as Xeron laser guidance, ISRA 3D vision, etc., that the overall technology is advanced. Therefore, MIR Rui Industry believes that domestic manufacturers will not only increase investment in products and develop more process packages, but also need to conduct multilateral cooperation with more peripheral suppliers to break through technology.

In the field of thick plate welding, STEP is considered to be an early and well-developed manufacturer among domestic brands . Its continuous optimization of various welding function packages has led many domestic brands in terms of functional perfection and maturity of thick plate welding. , and have been verified in a large number of practical projects. For example, the fuel tank robot welding solution launched by STEP in the construction machinery industry uses multiple advanced functions such as dual-machine collaborative welding, laser tracking, and positioner cooperation to improve welding efficiency and quality; the self-developed robot control system has realized The collaborative welding of up to 12 axes is the most among domestic robots.

STEP dual-machine collaborative fuel tank welding workstation

New energy vehicles may become an opportunity for domestic arc welding robots to enter the automotive industry

In the mid-to-high-end fields such as automobiles and auto parts, especially in the traditional fuel vehicle market, the weight of price in the equipment import option is relatively low. Car companies pay more attention to the stability, precision and efficiency of equipment. At present, foreign capital "four "Everyone" has almost monopolized this market, and domestic brands are less competitive. Therefore, MIR Rui Industry believes that the follow-up new energy vehicles, especially commercial vehicles, are the opportunity for domestic arc welding robots to enter the automotive industry. First of all, the manufacturing of new energy commercial vehicles does not require as much precision as passenger cars, nor does it require as much production capacity as passenger cars. This is an opportunity for domestic arc welding robots to break through and hone their equipment. Secondly, China is the main battlefield for new energy vehicles, and domestic car companies such as Great Wall, Changan, Baojun, and Wuling will support domestic robots even more.

Just like STEP's SA series welding robot, with the three-axis positioner and low-spatter welding system, it can realize the need for secondary treatment after welding, and the efficiency can be increased by more than 1.5 times; in the single robot double station + double robot composed of its robot In the double-station closed welding workshop, the car seat brackets produced have been widely used in various models of SAIC Roewe.

Application of STEPSA series welding robots in auto parts industry

At present, domestic arc welding robots in the automotive industry are only used in Tier2, Tier3 and other operating scenarios. There must be a place.

Scan the QR code to read on your phone