Walk into the STEP digital factory and witness the charm of eMES digital intelligence|September 28 new product launch invitation

- Views:

- Time of issue:2022-09-23 17:22

Walk into the STEP digital factory and witness the charm of eMES digital intelligence|September 28 new product launch invitation

- Views:

- Time of issue:2022-09-23 17:22

The wave of digitalization is sweeping the world, and discrete manufacturing transformation moves frequently. In the traditional manufacturing mode, the production workshop is in full swing, but it is difficult to predict the delivery time, and cannot accurately grasp the production progress, pass rate, production capacity and other data. Today, by deploying the MES system, manufacturing enterprises can grasp the production line, equipment operation status and output efficiency in real time, and take measures to avoid bad output caused by feeding and setting errors.

However, some people may question why the MES results are not satisfactory after investing a lot of cost and time and effort? In fact, in the final analysis, the traditional MES only stays at the information level and realizes business flow through documents, which can no longer meet the real needs of digital transformation.

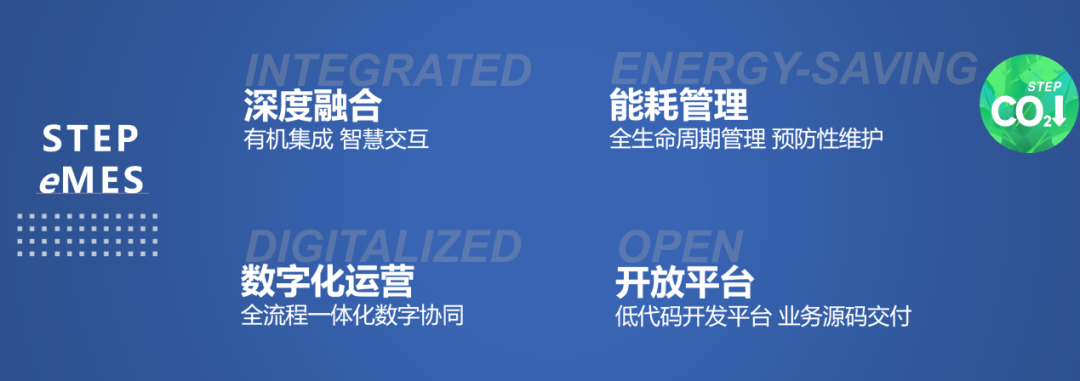

STEP is both a witness and an enabler of intelligent manufacturing. Based on its own deep understanding of pain points, STEP endows traditional MES with intelligence. The latest eMES system is able to coordinate with the inside and outside of the enterprise in real time to meet various personalized, customized and agile needs . Flexible and intelligent deployment of enterprise resources and capabilities.

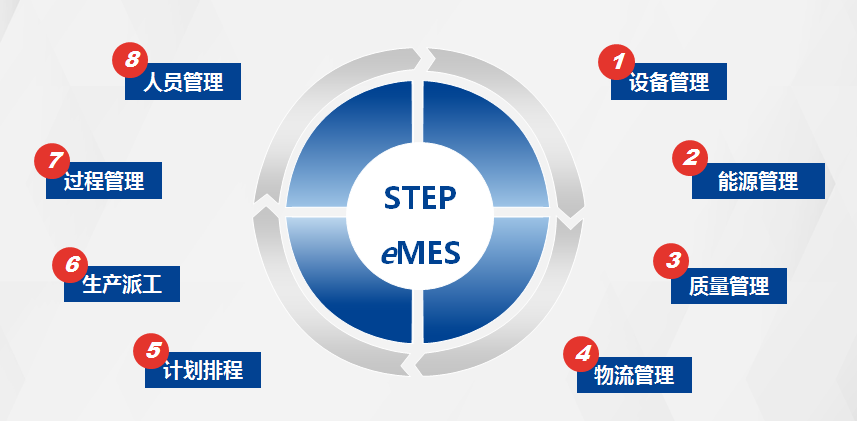

The eMES system has eight core functions, of which the two most prominent functions are equipment management and energy management , which can realize equipment energy consumption difference analysis and energy consumption improvement, preventive maintenance, equipment ledger management, equipment real-time monitoring, etc. eMES has been fully verified in the STEP factory until it is mature, and will be integrated into the overall solution of intelligent manufacturing to provide customers.

Eight core functions of eMES system

September 28 at 15:30

eMES Online New Product Launch Conference

It will be a grand opening!

We will share more product information with you to respond to the market's increasing demand for MES and the expectation of STEP intelligent manufacturing service upgrades. Many industry associations, well-known media and partners such as China Gongkong Network, Metal Processing, Modern Manufacturing, etc. participated in the grand event, and we sincerely look forward to your visit!

Scan the QR code to read on your phone