Endless Innovation丨STEP "Cube Elevator" control system put into operation

- Views:

- Time of issue:2017-12-01 00:00

Endless Innovation丨STEP "Cube Elevator" control system put into operation

- Views:

- Time of issue:2017-12-01 00:00

On November 8, 2017, in Fuzhou Luozhou Elevator Industrial Park, a special test tower for a super "Rubik's Cube Elevator" with an investment of 10 million yuan attracted the attention of elevator industry professionals and media from all over the country. There is only one elevator shaft in this 60-meter-high test tower, but seven passenger elevators with a load of 1350 kg are installed in the shaft.

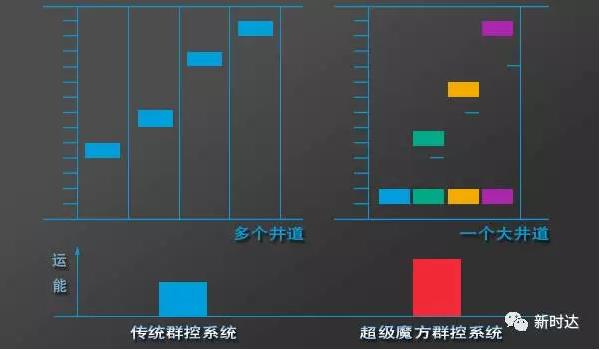

How to control and schedule multiple elevators in a shaft to run safely and efficiently, so as to maximize the elevator capacity and reduce the space of the shaft, is a world-class problem. STEP's research and development team has the courage to innovate and has developed a complete control system for the "Magic Cube Elevator". Through the cooperation with Fuzhou Kuaike Elevator Industry Co., Ltd., 7 elevators in one shaft can run at the same time, which greatly improves the elevator capacity and reduces the space of the shaft. This system has the following characteristics.

1) Ultra-high-level safety technology

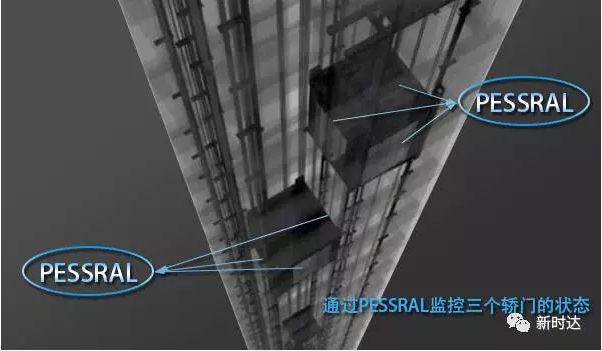

· Several sets of SIL3-level PESSRAL (programmable electronic safety-related system) are used to ensure the safety of the elevator.

· When the car is running or docking, PESSRAL monitors the status of the three car doors of each car. Once the car door fails or malfunctions, PESSRAL will control the elevator to enter the safe state immediately.

2) Fully redundant control technology

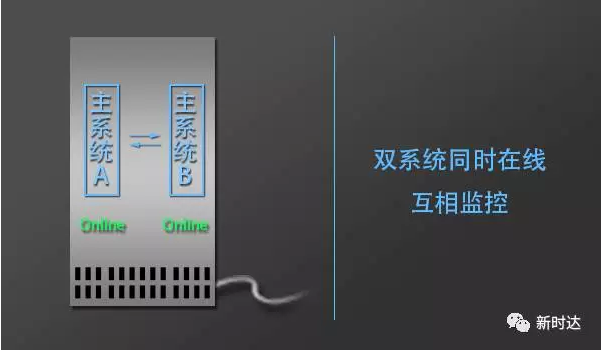

· Each elevator uses a "dual system", and the two systems are online at the same time and monitor each other. When one master control system fails, another master control system seamlessly takes over the control of the elevator and sends an alarm through the IoT device. The redundant system ensures the reliable operation of the Super Cube elevator and provides additional maintenance time.

3) Unique control algorithm

· The combination of DCS distributed control calculation and centralized control calculation is used, which greatly reduces the calculation burden of the group board, reduces the bus load, and improves the anti-interference performance.

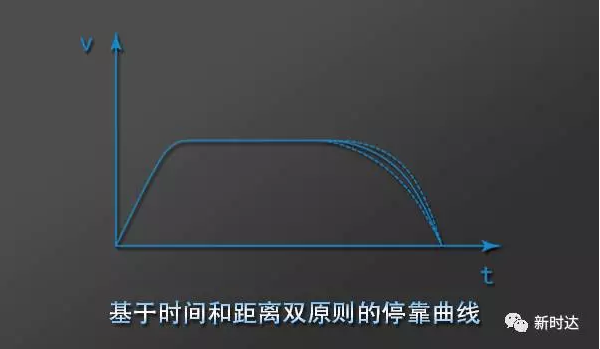

The stop curve based on the dual principles of time and distance helps to reduce the waiting time for transfers, and realizes that the waiting time for transfers is less than 5 seconds.

4) Leading destination-level dispatching algorithm

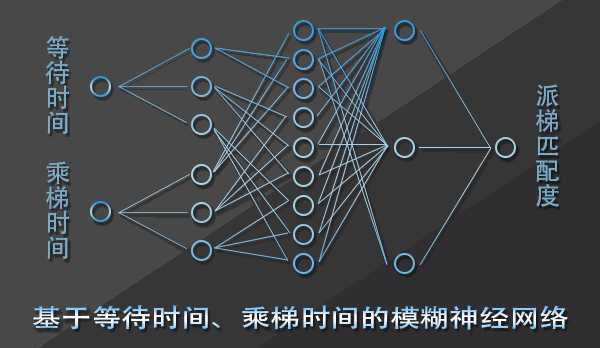

· The fuzzy neural network algorithm based on waiting time and waiting time is used. Based on the current state of each elevator, weights are assigned to the state variables of the elevators, combined with fuzzy paths and neural networks, the results are judged according to different optimal index functions, so that the operating efficiency of the elevators reaches the highest.

STEP has more than 20 years of experience in the research and development of elevator control systems, and has profound research and development strength and technical background in the field of elevator control. We will continue to pursue the innovation of the elevator control system, continue to seek technological breakthroughs, and continue to make our greatest contribution to the progress of the elevator industry.

Scan the QR code to read on your phone