Smart technology for a better future丨STEP robot stars shine at the CIIF

- Views:

- Time of issue:2017-11-10 00:00

Smart technology for a better future丨STEP robot stars shine at the CIIF

- Views:

- Time of issue:2017-11-10 00:00

The 2017 China International Industry Fair was grandly held at the National Convention and Exhibition Center (Shanghai) on November 7-11. STEP participated in the professional robot exhibition area, booth number: 7.1H-B242. STEP exhibits include: SD900 high-protection desktop robot, SRC2.6C drive and control integrated control system, robot intelligent work island, robot visual recognition/force control technology, SCARA robot application technology, servo drive core components, and automotive flexible production line Virtual debugging technology, etc.

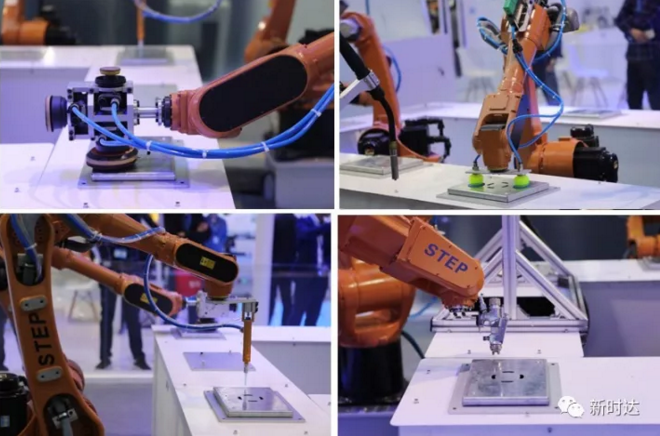

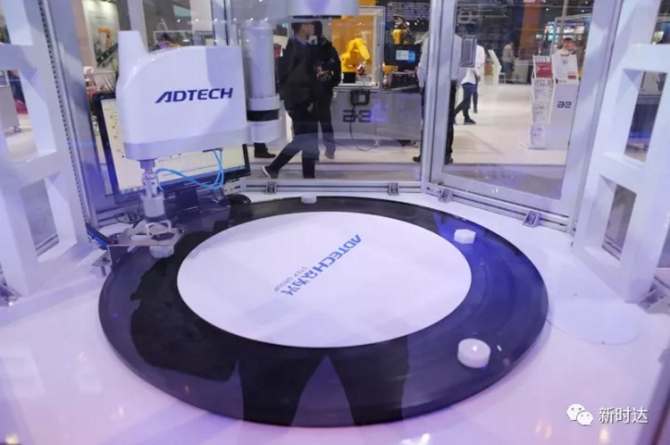

SD900 high-protection desktop robot

adopts lightweight arm design, compact and simple mechanical structure, repeated positioning accuracy can reach ±0.03mm, and can perform flexible operations in a small working space under high-speed motion to meet flexible production need.

· IP67 high protection level, can effectively cope with the harsh production environment, specially formulated for process applications in low-load and complex environments such as grinding, polishing, handling, and assembly.

SD900 high protection level desktop robot丨SRC2.6C drive control integrated control system

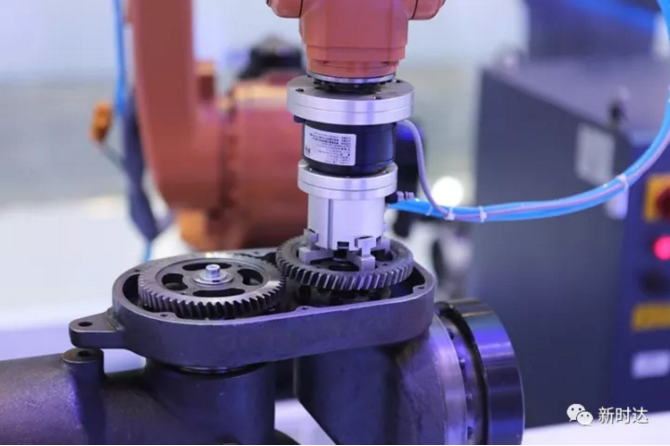

SRC2.6C drive control integrated control system

drive control integrated, modular design, the performance has reached the international advanced level of similar products. Excellent dynamic response and control accuracy, current loop period 10us, current loop bandwidth ≥ 2.5kHz.

· The performance is 80% higher than that of the original product

· The volume is less than 1/9 of the original product

· The weight is less than 1/7 of the original product

The flexible assembly workstation

uses the six-dimensional force/torque sensor to design an impedance control algorithm to make the end of the robot soft, and is suitable for assembly, grinding, depalletizing and other fields.

Flexible Assembly Workstation

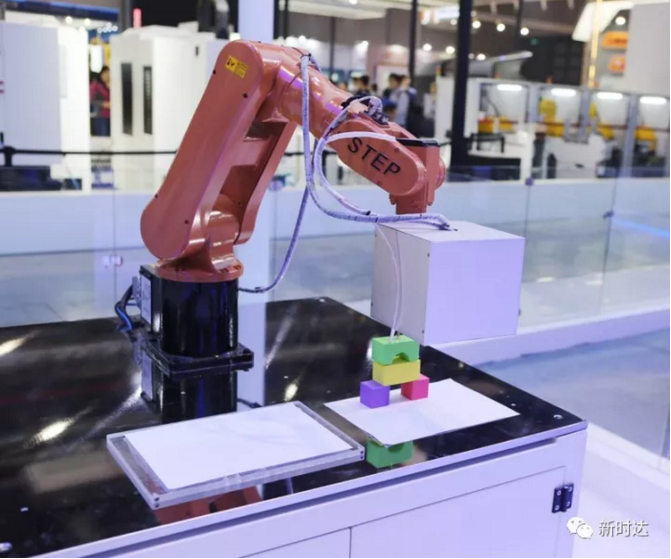

The 3D vision robot assembly system

uses Raichen 3D vision technology to perform 3D positioning of multiple scattered workpieces. Use the STEP 6-axis robot to locate and select the required parts from the scattered parts for assembly. Application industry: assembly, sorting.

3D vision robot assembly system

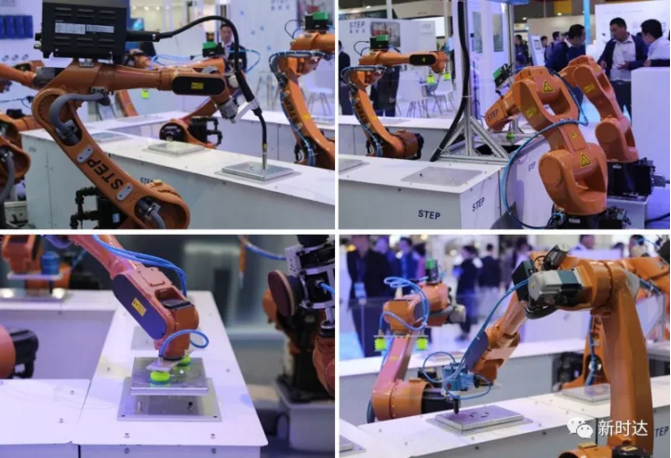

The robot intelligent work island

The work island concentratedly demonstrates the cutting-edge technology and typical applications of STEP high-quality industrial robots in the process of product transfer processing. In the sequential processing of products, various processes such as STEP robot 3D visual recognition, welding, handling, grinding, gluing, rivet riveting, and spraying are demonstrated in sequence. Industry application: assembly, grinding, decoding stamping.

Robot intelligent work island

Robot plug-in workstation

SCARA robot cooperates with AVS vision system for IC plug-in. Industry application: assembly of precision parts.

Robot Plugin Workstation

Multi-machine synchronous following workstation

SCARA robot cooperates with AVS vision system to realize synchronous following sorting. Industry application: food, packaging industry, etc.

Multi-machine synchronous follow workstation

The robot arc synchronously follows the sorting workstation.

The SCARA robot cooperates with the AVS vision system to realize the arc synchronously follow pick and place. Industry application: dynamic dispensing, assembly.

The robot arc synchronously follows the sorting workstation

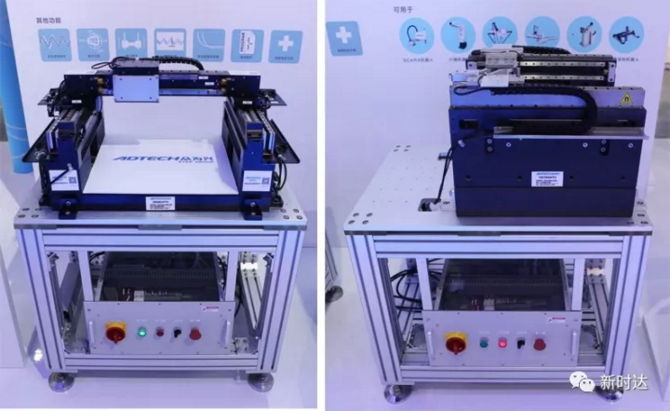

The H-type high-speed motion platform

AMC1600E realizes the control scheme of 2-axis parallel planar robot. Industry application: assembly, grinding, decoding stamping.

H-shaped high-speed motion platform丨Planar parallel mechanism platform

The planar parallel mechanism platform

AMC1600E realizes the control scheme of 2-axis parallel planar robot. Industry application: SCARA, DELTA, 2-axis planar parallel robot, etc.

AMC 1600E bus control platform

AMC1600E complete EtherCAT bus control solution. Industry application: packaging, testing, winding, assembly line, etc.

AMC 1600E bus control platform丨EtherCAT bus type linear motor drive system

The EtherCAT bus type linear motor drive system

is based on the synchronous control scheme of multiple linear motors based on the EtherCAT bus, which is used in LED, 3C electronics, SMT patch, laser cutting and other industries.

EC232 new generation multi-axis motion control system丨SMART compact multi-axis drive control system丨High-performance AC servo system

High-power servo-port automation application solution丨All-electric injection molding system application solution

High-power servo-port automation application solution丨All-electric injection molding system application solution

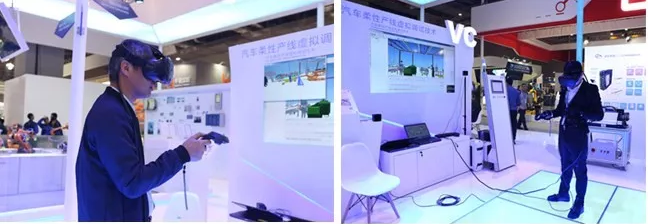

The application of virtual commissioning technology for flexible production lines of automobiles The

application of this technology can shorten the on-site commissioning cycle and reduce downtime. Operators can be trained in a virtual environment, reducing on-site PLC program errors, improving the quality of on-site robot trajectory, reducing the workload of engineers on site, and providing a safe testing environment.

Application of Virtual Commissioning Technology for Automobile Flexible Production Line

At the STEP booth, industry leaders, new and old customers, enthusiastic audiences, and various media flocked to discuss new technologies, understand new products, and exchange new information.

Robot • Intelligent Technology • Future Factory

STEP Robot is committed to providing the most competitive industrial robot and automation comprehensive solutions for the field of intelligent manufacturing, helping enterprises to upgrade their industries, contributing to Made in China 2025, and jointly creating a better future.

STEP booth

Scan the QR code to read on your phone