STEP robot participated in China Manufacturing Expo

- Views:

- Time of issue:2017-03-16 00:00

STEP robot participated in China Manufacturing Expo

- Views:

- Time of issue:2017-03-16 00:00

Exhibition Overview

From March 9th to 12th, the 13th China Manufacturing Expo was held in Tianjin Meijiang Convention and Exhibition Center. The exhibition includes a number of professional exhibition areas for machine tools, robots, automation, sheet metal cutting, and 3D printing.

In the robot exhibition area N2-B28, STEP displayed the robot aluminum template welding workstation, cutting workstation, robot advanced operation training workstation, machine tool loading and unloading workstation, and intelligent "backgammon" robot workstation.

Welding specification of robotic aluminum template welding workstation

: STEPSA1400 welding robot, using gas shielded welding, intelligent arc start, can select the corresponding welding specification from the expert library according to the thickness of the workpiece plate and the form of the weld.

Technical advantages: stable performance, high-quality welding, ensuring uniformity; continuous production 24 hours a day, improving productivity; improving working conditions, reducing the requirements for workers' operating skills; automatic welding of batch products, saving floor space. At the same time, motion expansion, special fixtures, guardrails, safety gratings, dust removal equipment, etc. can be added according to customer requirements.

Scope of application: used for aluminum formwork welding operations, such as welding of aluminum formwork materials for construction, etc.

Robot aluminum template welding workstation

Robotic Cutting Workstation

Technical performance: The workstation adopts SA1800 robot, which is used to cut arbitrary curve bevels: cut various profiles, such as H-shaped steel, L-shaped steel, U-shaped steel tenons and process holes; cut various pipes, such as square pipes or round pipes, etc. (need to be equipped with a chuck).

Cutting forms: flame, plasma, laser and high-pressure water, etc.

Robotic Cutting Workstation

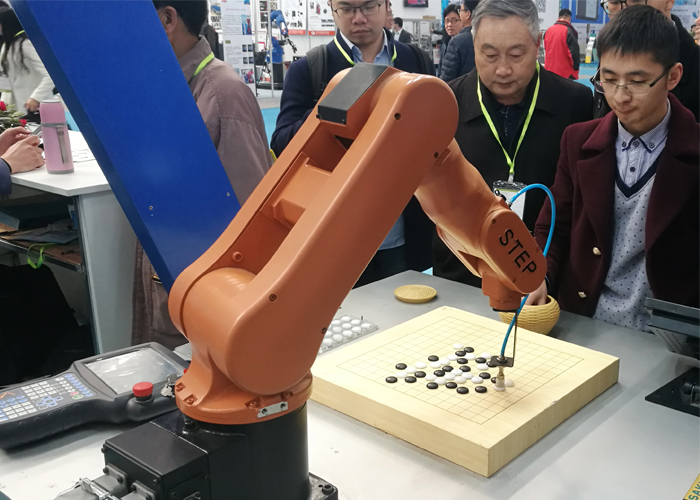

Intelligent "Gobang" robot workstation

Artificial Intelligence AlphaGo. Last year, AlphaGo defeated the world's top Go player Lee Sedol 4:1. At the beginning of this year, the new version of AlphaGo-Master played against dozens of top Go players from China, Japan and South Korea, achieving a record of 60 wins and 0 losses. AlphaGo artificial intelligence makes human blood boil.

STEP intelligent robot. At the exhibition, the STEP intelligent "backgammon" robot satisfies the eager desire of ordinary people to play against artificial intelligence robots.

The "Gobang" robot is played by the STEPSD700 robot. Through the visual recognition system, it can accurately identify the player's position, and the computer program can judge the player's intention, and estimate the player's possible position in the next few steps, and calculate the optimal position in advance. coping methods.

The "Gobang" robot workstation independently designed by the STEP robot R&D team fully reflects STEP's innovative capabilities in robot software development and system control. According to the R&D engineer, in the actual game against the robot, the probability of the chess player winning is very low, which is extremely challenging.

Application range: SD series robots are small in appearance and light in weight, and can complete high-speed, high-precision loading and unloading, sorting, assembly and other tasks, and are widely used in 3C and other industries.

chess player vs robot

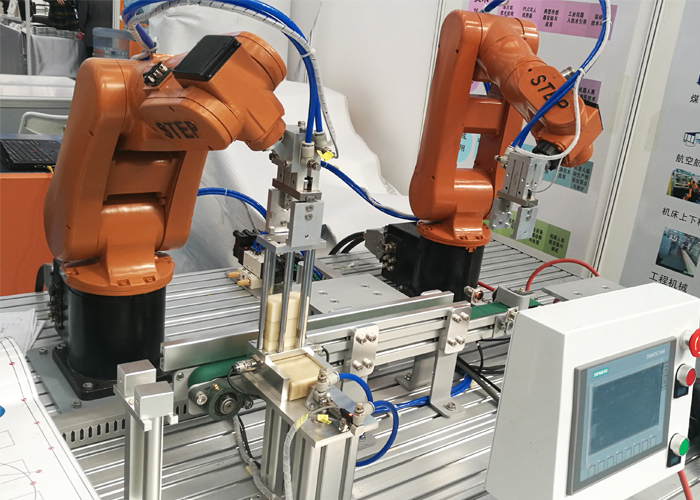

Robot advanced operation training workbench

System composition: The main structure of the equipment includes SD500, SD700 desktop robots, simulated loading and unloading modules, simulated palletizing modules, basic training modules, electrical control systems and safety protection devices. The robot is installed on the workbench made of aluminum profiles, and the layout of other modules is reasonable and easy to operate.

The operation runs. Within the movement range of the robot, it can realize the cyclic operation of the entire workstation, isolate the simultaneous movement of man and machine, and improve the safety of the equipment. The moving part of other modules adopts cylinder action, which is convenient for maintenance and debugging, and the overall table top is clean and beautiful.

Robot advanced operation training workbench

Robotic machine tool loading and unloading workstation

At this exhibition, the machine tool loading and unloading workstation displayed by Tianjin Taijie Precision Machinery Co., Ltd. uses the STEPSA1400 robot. Using robots to replace manual loading and unloading operations can achieve the goal of reducing staff and increasing efficiency, and also provides an effective way for traditional operations to achieve industrial upgrading.

Tianjin Taijie Precision Machinery - Machine tool loading and unloading workstation

At the same time, at the technical exchange meeting held by Tianjin Robot Industry Association, Xu Long, the marketing manager of STEP robot, gave a technical exchange speech.

Scan the QR code to read on your phone