Applications:Apparel industry

Keywords:Motion control board application

Related products:

Auntie Wang's house next door has an old sewing machine that is wiped spotlessly clean every day. The culture and emotion contained in old objects have long surpassed their value through the years. Some objects may have been withdrawn from life, but some are in constant evolution, just far from the public eye.

Old sewing machines

Just as today's sewing machines have long since ceased to be what they were, foot hand crank has been replaced by motor drive, gradually freeing people from laborious physical operation, and the scenes of use are rarely at home, but have shifted to factories. With the continuous development of control systems, fully automated sewing equipment with better processing accuracy, production efficiency and stability - template machines - are being rapidly introduced into the market.

The evolution of sewing machines

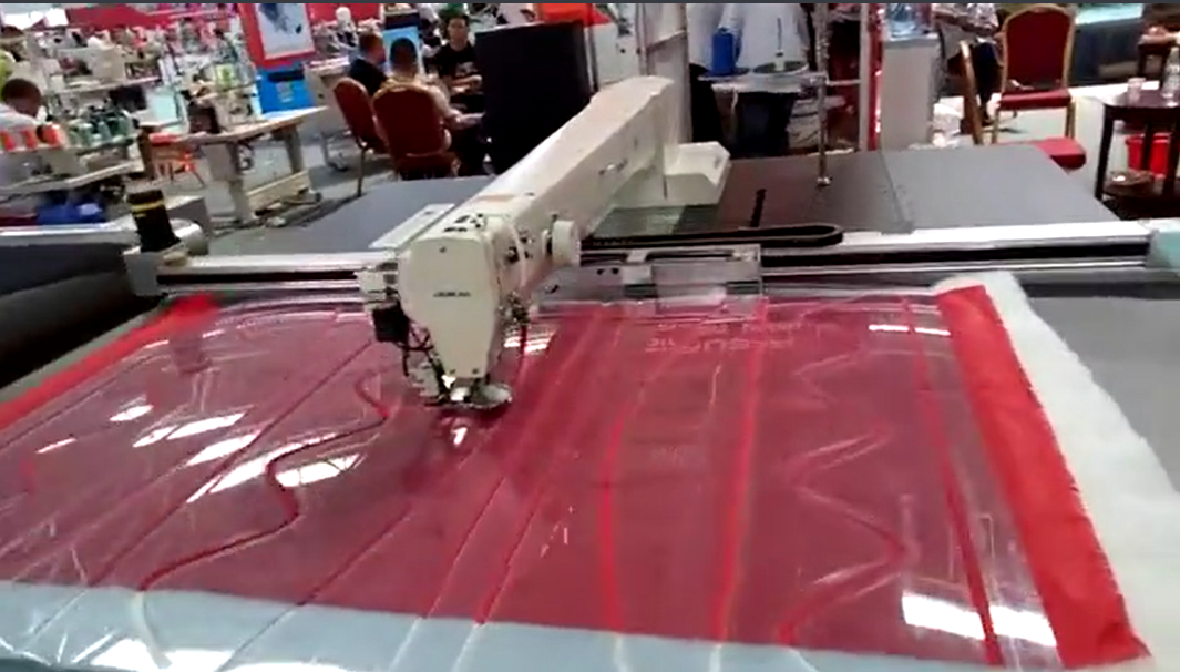

A stencil machine is a type of general-purpose sewing equipment that has the functions of a flat sewing machine and part of an embroidery machine. The worker first makes various slots on the PVC or acrylic board as needed for the garment size, and then fixes them on the stencil machine. When sewing, the slots made in front are the trajectory of the thread, making sewing more accurate and fast. This not only improves efficiency, but also reduces the rate of defective products and the degree of reliance on professionals.

According to the person in charge of the control system of the template machine of ZWX (a member of the New Times Group), the fully automated template machine has incomparable advantages over traditional sewing equipment. The template machine can undertake most of the sewing process, its sewing quality is high and can be continuously repeated; it is easy and fast to prepare the template and operate by pressing the button; one worker with no professional skills required can operate multiple machines, which is suitable for flowing operations. With the popularity of automation equipment, the textile industry will also move from automated inline machines to the trend of smart factories in the future.

For the template machine market, ZWX has launched MTC500 series template machine control system. It provides multi-axis control, according to different needs can be configured with stepper and servo drives, support all kinds of mainstream spindle motors on the market, processing speed up to 3600 rpm, the system runs smoothly, the machine processing smoothly, mainly used in clothing, home textiles, car cushions and other sewing processing equipment.

Application cases of MTC500 template machine

MTC500 series template machine control system features

System adopts dual CPU control mode, two CPUs are responsible for application layer data parsing and motion control algorithm, which makes the system movement smooth and efficient;

Pulse frequency up to 4 megabytes, high machining and positioning accuracy;

The spindle servo is integrated into the system, and the spindle is controlled and monitored through the internal bus, truly realizing fast, accurate and stable spindle processing;

Laser and brush functions are pre-processed to ensure that all kinds of trajectory changes will be smooth and smooth acceleration and deceleration transitions to avoid overshoot or missed machining.

The system adopts one-button operation, the equipment will work automatically when the start button is pressed, and any abnormality in the process will automatically alarm and stop;

The system has automatic template identification function, which can reduce the process and workers, significantly improve the efficiency and conform to the standardized operation process.