How does workshop brain MES create a new blue ocean? STEP eMES takes you into the digital factory

- Views:

- Time of issue:2022-10-14 00:00

How does workshop brain MES create a new blue ocean? STEP eMES takes you into the digital factory

- Views:

- Time of issue:2022-10-14 00:00

01 The solution to the supply chain crisis

With the pandemic of the new crown epidemic, the shortage of semiconductor chips and the war in Ukraine in recent years, coupled with the alternate impact of scheduled and fixed-point power cuts in the past two years, the manufacturing supply chain has been greatly impacted. In 2021, social media mentions of the supply chain reached 25,636 times, a 13-fold increase from 2019. The world order that enabled globalization and those resilient, efficient supply chains are falling apart, and everyone is looking for supply chain security within the region.

Therefore, it is a good choice for companies to use technology to reconfigure the supply chain and provide new efficiencies through intelligent production. In recent years, domestic intelligent manufacturing and industrial cloud platforms have developed rapidly. It is optimistically predicted that by 2035, the supply chain will be fully digitized and automated. Companies should therefore focus on the convergence of technologies to reshape supply chains to be lean and self-sufficient—but how?

To answer this question, let's imagine a scene: in a busy auto parts production workshop, the automated production line is running in an orderly manner. The planner releases the production tasks from ERP, and the production supervisor specifies the workshop operation plan according to constraints such as production capacity. But before that, the process designer released the process management to the manufacturing department, and then the workshop operator controlled the equipment to start the production task, the parts were assembled one by one and sent off the production line, and the data was fed back to the planner after the production was completed. The whole process is efficient, accurate, and most importantly, less staff-intensive than traditional workshops. What realizes all this is the most important one in the current intelligent manufacturing software——MES.

02 A market full of competition

As the brain of the workshop, MES is located in the industrial control system at the bottom of the plan management system (ERP). It provides operators/managers with plan execution, tracking and monitoring of all resources (people, equipment, materials, customer needs, etc.) current status.

Driven by the national intelligent manufacturing strategy, the growth rate of the overall MES market has grown significantly in recent years; in 2017, 2018, and 2019, MES has grown rapidly. One of the reasons is that the restart of petrochemical, chemical, metallurgical, tobacco and other industry projects has a significant impact on the overall market. market contribution. However, as the growth rate of traditional industries will slow down in the next few years, and the MES market will become more mature, its growth will stabilize within a certain range.

In most intelligent manufacturing projects, MES will be used, and MES system can also be implemented as a project alone. Among the MES projects in the past few years, nearly 30% belong to intelligent manufacturing projects.

Because MES and even the entire field of intelligent manufacturing is an emerging industry and its development is in its infancy, each MES system has its own unique application and design. Therefore, in 2019, there are hundreds of MES suppliers in China, the concentration of suppliers is relatively low, and the brands are relatively scattered. Many foreign-funded manufacturers entered China's smart manufacturing market with their long-term accumulation in the field of industrial automation and gradually became leading manufacturers, but none of them accounted for more than 10%.

Other suppliers include some manufacturing manufacturers. These manufacturers were originally MES customers, but due to their high level of IT technology, they will independently develop MES software that is more suitable for their own business processes according to the business conditions of their factories. At the same time, gradually promote its self-developed MES products.

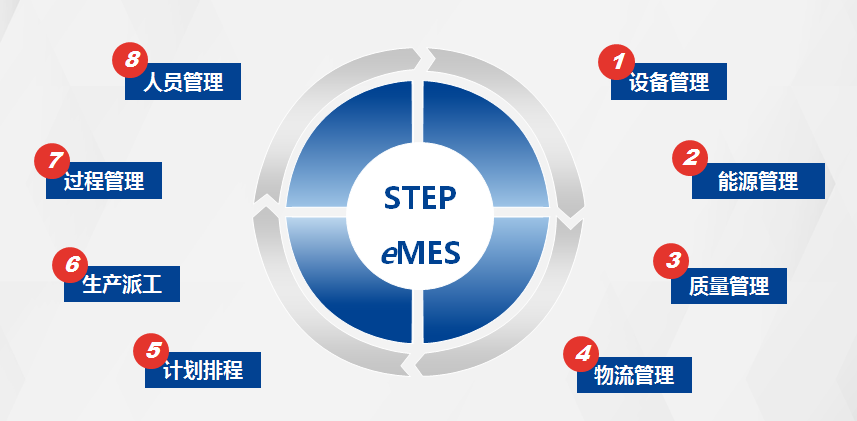

Taking STEP as an example, as a veteran automation manufacturer, it has also responded to the general trend of intelligent manufacturing in recent years, and has begun to develop intelligent manufacturing-related software systems. On September 28, 2022, STEP released a new generation of workshop manufacturing management system - eMES. E stands for STEP's creative concept for the new generation system, that is, evolutional. STEP wants to use this to convey a message, that is, compared with traditional MES, which can only realize the effect of production informatization, this STEPeMES system actually needs to go to a higher level-production intelligence.

The eMES system has eight core functions, of which the two most prominent functions are equipment management and energy management, which can realize equipment energy consumption difference analysis and energy consumption improvement, preventive maintenance, equipment ledger management, equipment real-time monitoring, etc. eMES has been fully verified in the STEP factory until it is mature, and will be integrated into the overall solution of intelligent manufacturing to provide customers.

The reason why these functions can be achieved is because eMES connects links such as SCM, CRM, ERP, PLM, and WMS. Specifically:

1. The production order data required for eMES planning and scheduling will be obtained from ERP in real time through system interaction, providing a complete data source for eMES subsequent production and operation management;

2. The material requirement planning data generated by eMES scheduling is synchronized with WMS to guide logistics operators to distribute materials to ensure the continuity of production;

3. Through the synchronization of the PLM system and eMES, the company can realize the life cycle control from product development to product realization. PLM completes the process BOM data support required by eMES, and at the same time uses eMES to complete the information verification and data feedback of PLM, so as to Contribute to the technical perfection and improvement of the company's technical department;

4. In such an ingenious structure, eMES can seamlessly connect ERP, PLM, BI and many other systems through the existence of OPEN API, providing the necessary technical support for the high degree of synergy of STEP digitization.

A major pain point of industrial intelligent manufacturing has always been the difficulty of connecting various links. The idea of STEPeMES is to connect through OPEN API to complete the seamless connection between multiple systems, avoiding data import and export or data docking. Occurrence of various BUGs or other adverse situations. Secondly, the existence of OPEN API can prevent other systems from being directly connected to the ERP system, so that it will not be damaged, thereby reducing the risk of failure. Finally, OPEN API can complete the high degree of coordination among many STEP systems and realize real-time data synchronization between different systems. Reduce the work pressure and work intensity of employees.

In addition, STEP's eMES system can not only realize the informatization and readability of workshop production, but also perform quality inspection and real-time feedback under AI visual inspection, so that the automatic operation of the entire workshop is more intelligent rather than "mentally retarded". "Mechanization". This is also a major drawback of traditional so-called automated production. Moreover, STEP also pays special attention to the energy consumption management of equipment and real-time monitoring of equipment, which reduces the loss of equipment operation. Of course, all of this operates under the visualized data platform, which truly realizes the controllable "workshop brain" operation.

some opinions

Generally speaking, MES, as an intelligent manufacturing software system at the front line of production, has been widely used in petrochemical, metallurgical and other process automation industries for a long time in the past. At present, MES has a high penetration rate in these process automation industries. Room for growth is limited. However, discrete automation industries such as electronic manufacturing, lithium batteries, and home appliances have developed rapidly in recent years, which will be the main growth point of MES in the future and the focus of competition among various related companies. In addition, the automotive industry has a relatively high degree of automation and has generally applied MES systems. Some competitive companies in this industry can continue to tap market potential and win the market by relying on more detailed workshop solutions and more intelligent and convenient operating systems.

It is expected that in the future, as the pace of transformation and upgrading of China's manufacturing industry will become faster and faster, the requirements of various manufacturing companies to improve the efficiency and security of the supply chain will become more and more urgent. From now on, gradually carrying out localization substitution is a "blue ocean market" that should be firmly grasped for STEP and other manufacturers.

Source of this article: Rui Industry

Scan the QR code to read on your phone